A beverage formulation and method of making such beverage that is derived from extract from coffee cherry husks and coffee cherry pulp

A coffee husk and extract technology, applied in coffee extraction, coffee, food science and other directions, can solve the problem that coffee berries cannot be directly eaten by humans

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

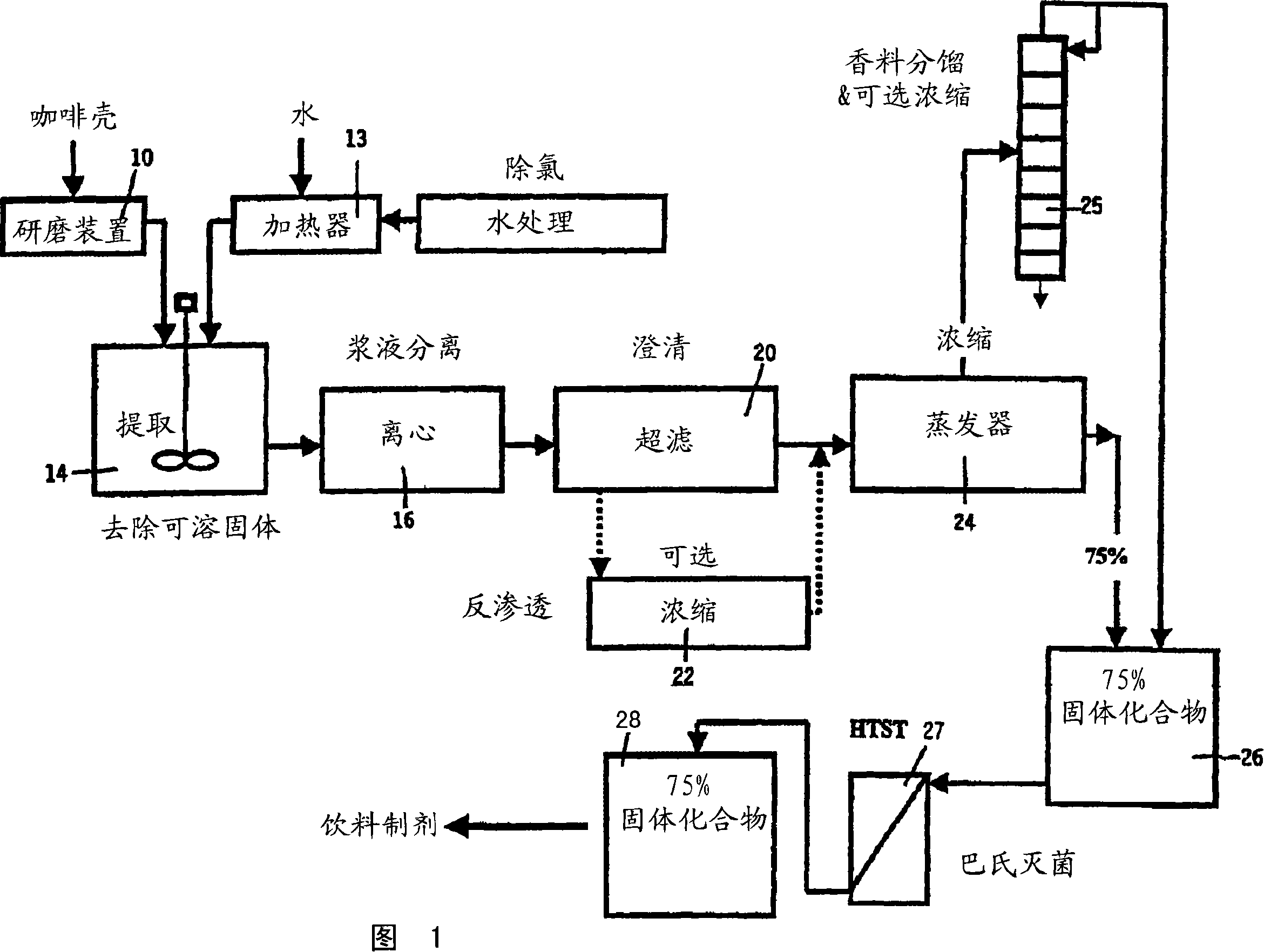

Method used

Image

Examples

Embodiment 1

[0054] About 500 kg of coffee husks (Mundo Novo species) were extracted with about 2500 kg of hot drinking water at 75° C. in countercurrent in a column extractor. Recover about 2000kg soluble solid content and be the extract solution of 6.3 ° Brix. The extract was centrifuged at 7°C through an Alpha Laval sludge removal centrifuge to partially remove suspended soluble solids. Subsequently, the centrifuged extract was filtered through an ultrafiltration system comprising a membrane with a 200,000k Dalton cut-off (ie PC1 membrane - FP200 / FPT20). A filter is provided so that the liquid extract is collected, while the retentate on the membrane is returned to the feed tank. Add the extract to the feed tank to maintain the desired working level. When all the extract has been added, the unit is run until the level of retentate returned is reduced to a level where further pumping is not possible.

[0055] Recover about 1300kg of the extract that obtains 5.5 ° Brix. The extract wa...

Embodiment 2

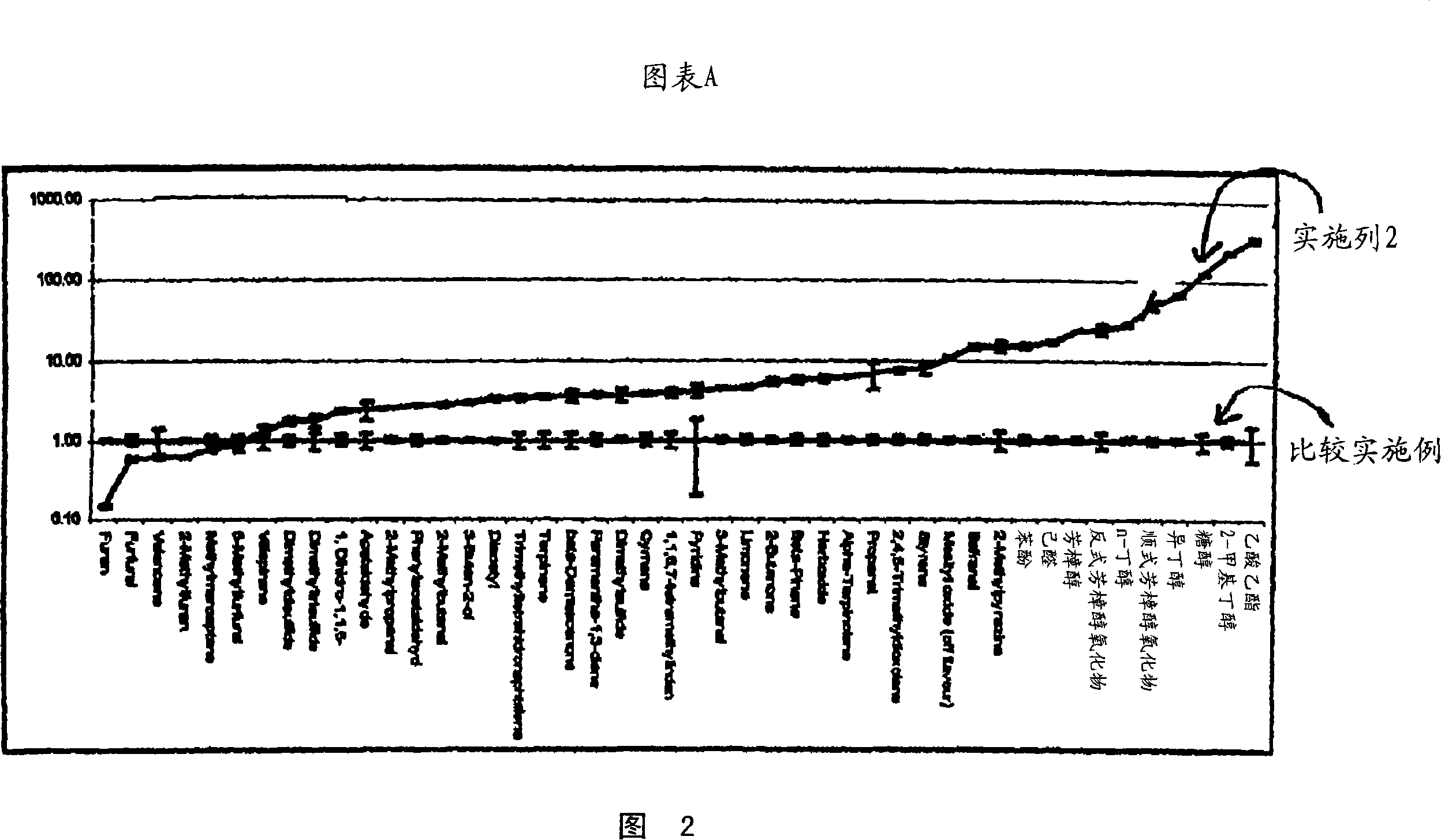

[0057] About 1300 kg of the ultrafiltration extract obtained in Example 1 was evaporated using a two-stage plate vacuum evaporator. The operating conditions are: a vacuum of about 1.75 bar and a temperature of about 55 to about 65C. The evaporator is equipped with a pre-stripping section to recover volatile components of the extract (ie fragrances) that would otherwise be lost during vacuum evaporation. Condensate containing volatile components was collected separately. The coffee berry concentrate produced by the evaporator had a Brix value of about 57.5° Brix. Table 2 below shows the analysis of the recovered perfume components.

Embodiment 3

[0059] Similar conditions were used as in Example 1, except that the coffee husk (Robusta species) was extracted. About 70 kg of Robusta extract was prepared. The extract was further ultrafiltered using the conditions in Example 02, but evaporated on a rotary pilot plant evaporator. Condensate and concentrate were collected separately. Table 2 below shows the analysis of the products, including the recovered perfume components.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com