Jet stream type erosion abrasion test device

A wear test, jet-type technology, applied in the field of erosion wear test device, jet-type erosion wear test device, can solve the problems of occupying a large space, not a circulation system, short test period, etc., to achieve convenient operation and simple principle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

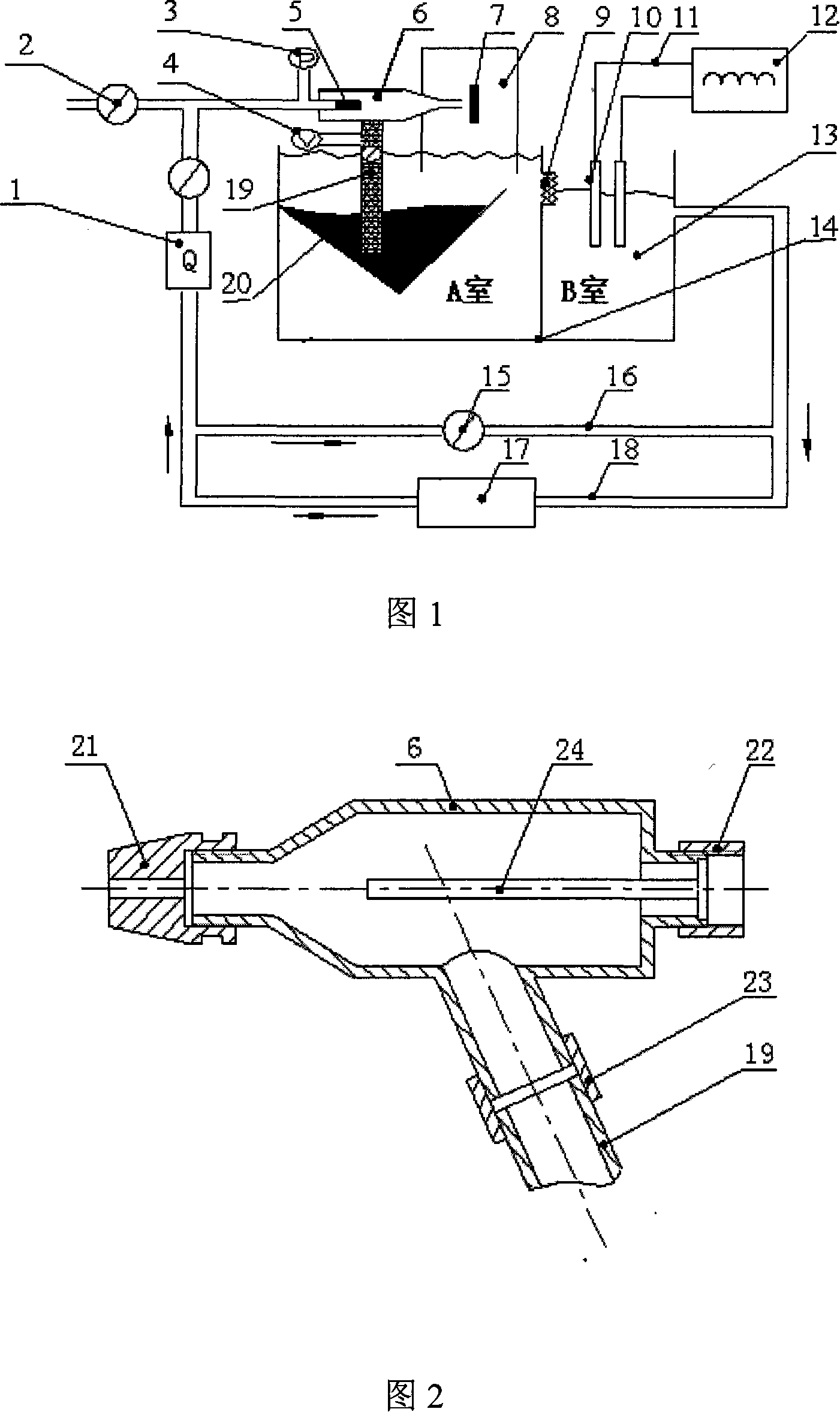

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0016] The invention is a test device for testing the erosion and wear performance of materials under the condition of erosion and wear, which can be used for the comparison test of the erosion and wear resistance of various wear-resistant materials, material selection and research on the erosion and wear mechanism.

[0017] Fig. 1 is a schematic structural diagram of an embodiment provided by the present invention. It includes a slurry control circulation circuit part composed of a centrifugal pump 17 , a pipeline 18 , a flow meter 1 , a valve 2 and a pressure gauge 3 , and the circuit can also be provided with a branch circuit composed of a bypass valve 15 and a bypass pipe 16 . One end of the pipeline 18 is fixedly connected to the nozzle 5, and the front end of the nozzle 5 extends into the sample chamber 8, and the sample 7 is fixed by a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com