Highly-effective energy-saving chain type concrete spraying machine

A concrete spraying machine, high-efficiency and energy-saving technology, applied in the direction of construction, building structure, building material processing, etc., can solve the problems of high operating cost, unreliable sealing, high energy consumption, etc., to reduce return air failure and shrink the sealing area , The effect of increasing the sealing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

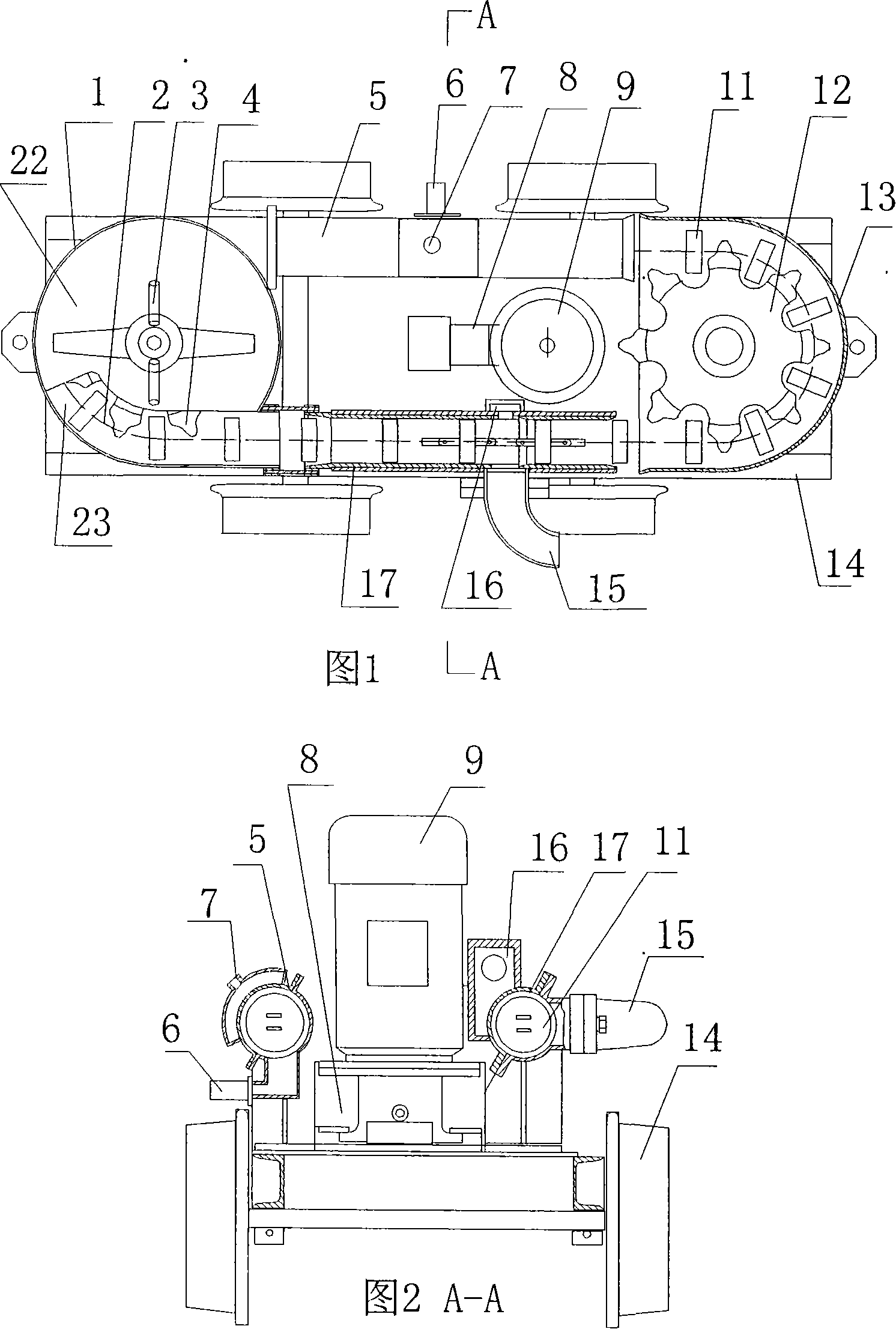

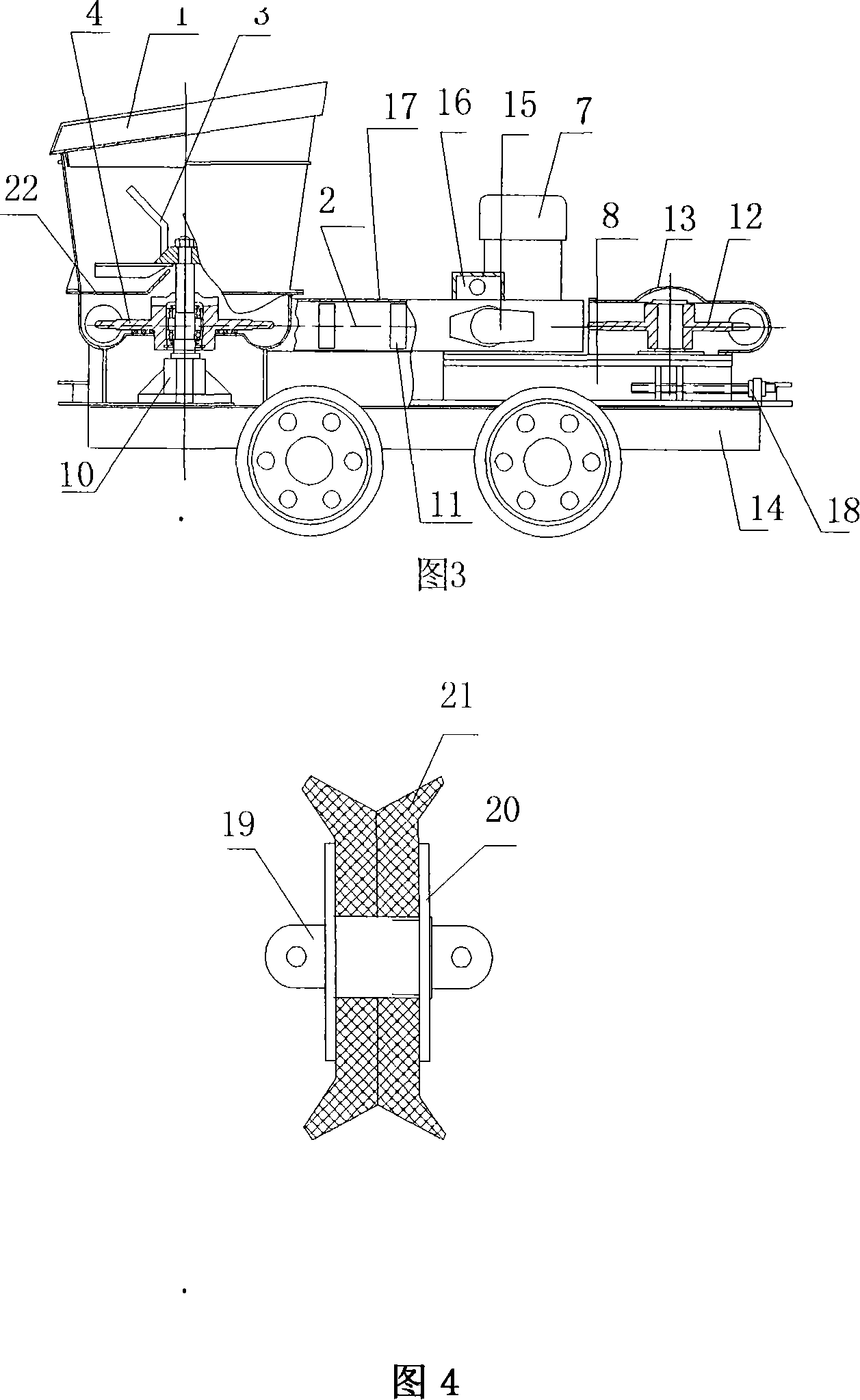

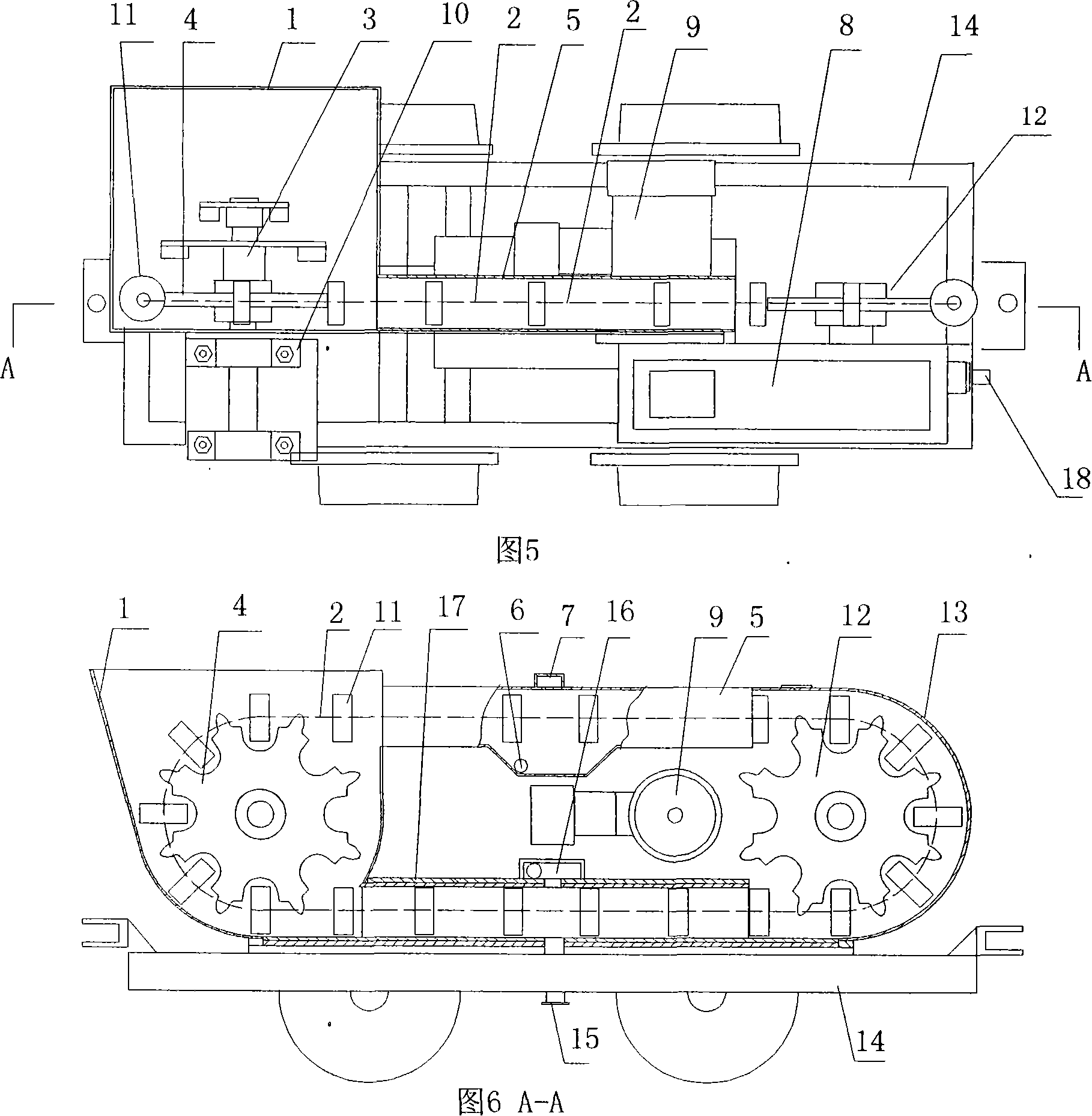

[0020] The high-efficiency and energy-saving chain concrete sprayer of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0021] As shown in the drawings, the high-efficiency energy-saving chain concrete sprayer of the present invention is composed of a chassis 14, a hopper 1, a reducer 8, a driving sprocket 12, a passive sprocket 4, a piston cylinder 17 and a series piston 11. The driving chain The power output shaft of the wheel 12 and the reducer 8 is connected horizontally on the right end of the chassis 14, the lower end of the shaft of the driven sprocket 4 is horizontally fixed on the left end of the chassis 14 through the bearing seat 10, and the passive chain of the agitator 3 is coaxially arranged. The wheel 4 is set in the hopper 1, the passive sprocket 4 and the agitator 3 are separated in the hopper 1 by a partition 22 in the upper and lower feeding spaces, and the edge of the partition 22 is provided with a fee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com