Four layers circulating type hydraulic pressure vulcanizing machine

A vulcanizing machine and circulation technology, which is applied in the tire industry, can solve the problems of high labor intensity of operators, unreachable process conditions, and influence on product quality, and achieve the effects of small footprint, suitable for social trends, and improved economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

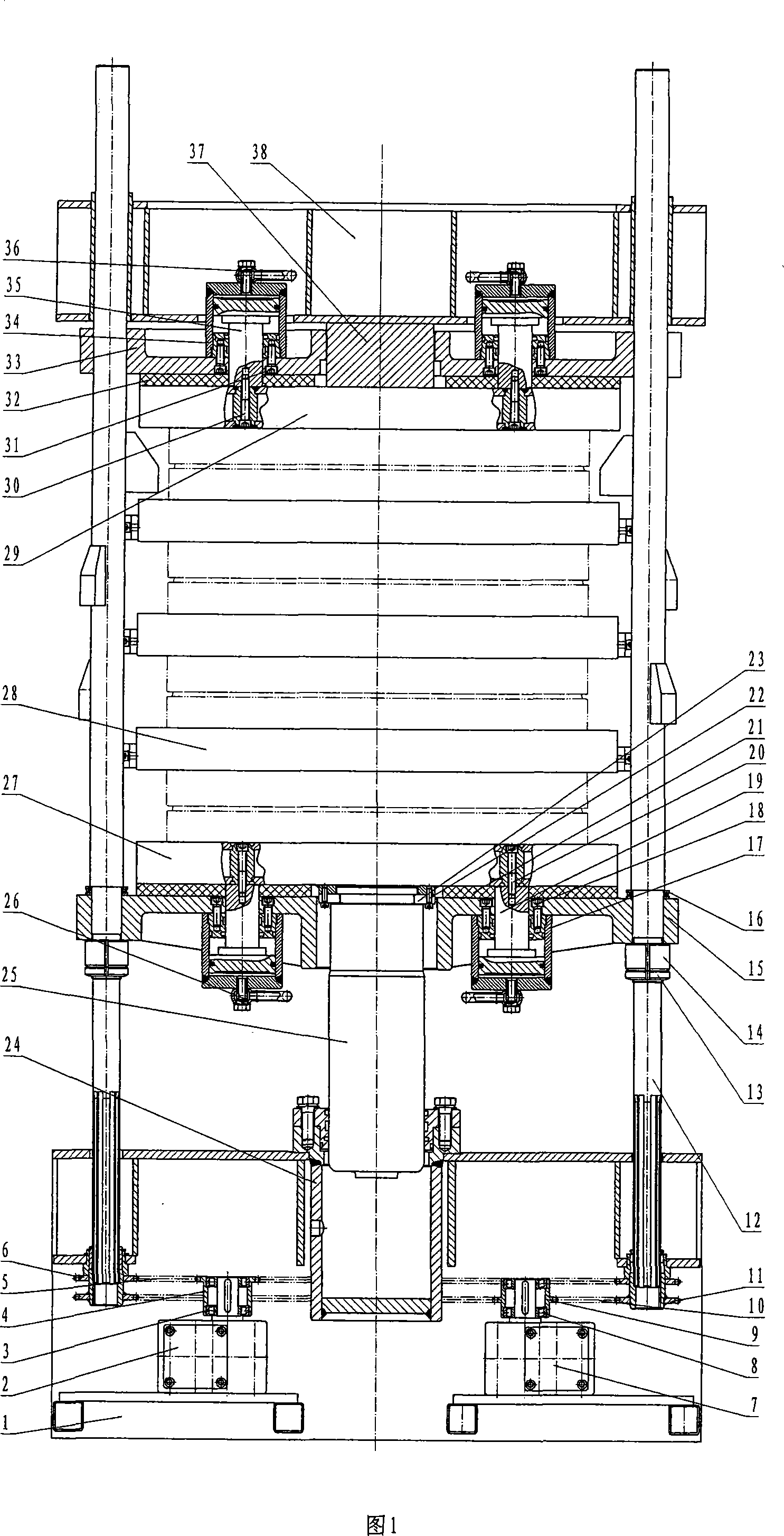

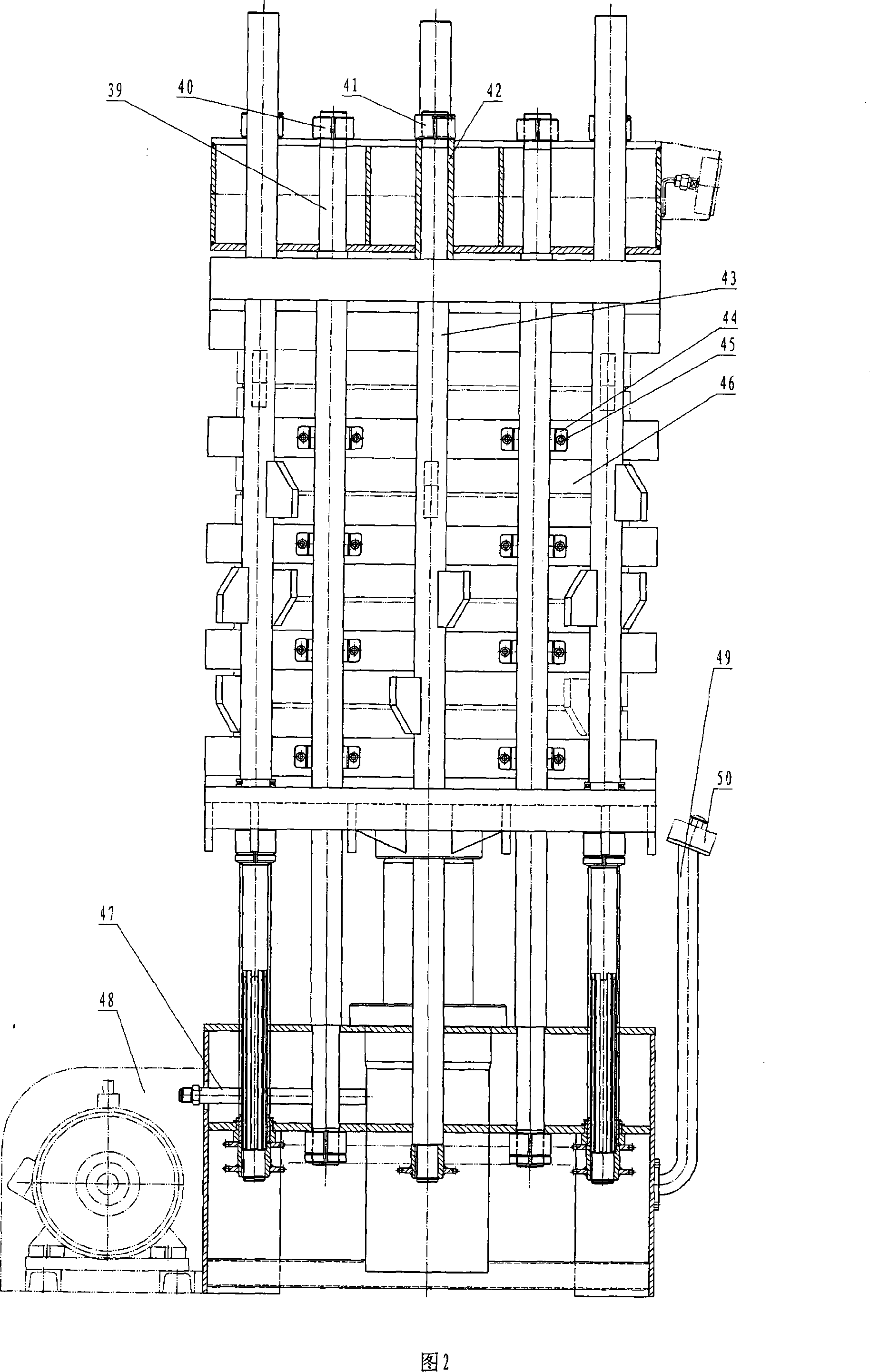

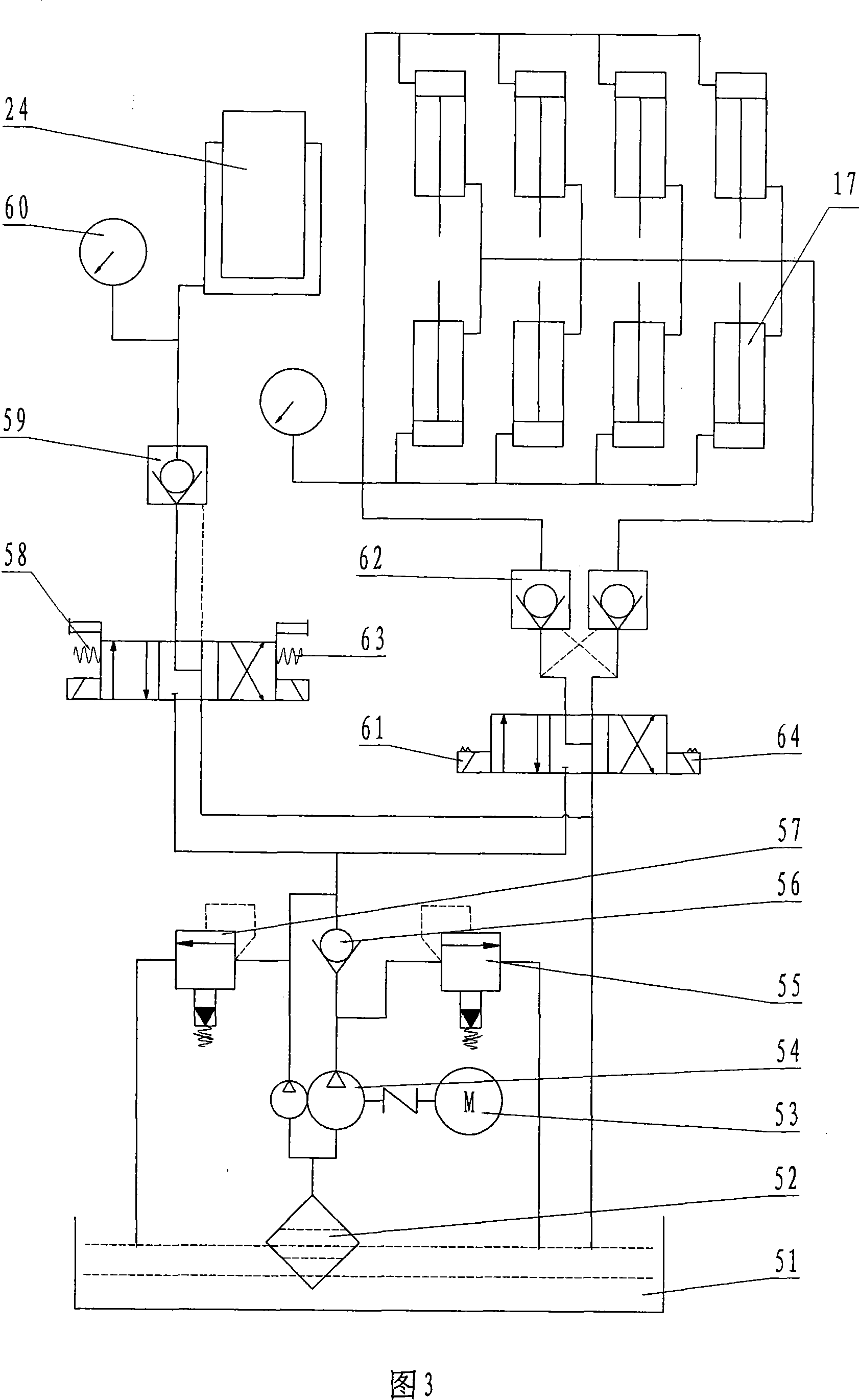

[0025] The present invention mainly consists of lower beam 1, 60°~120° two-stage swing cylinder 2, one-way bearing 3, driving sprocket 4, two-stage traction chain 5, passive sprocket 6, 120° single-stage swing cylinder 7, one-way Bearing 8, driving sprocket 9, single-stage traction chain 10, passive sprocket 11, lower pressure column 12, joint cap 13, nut 14, lifting plate 15, plane bearing 16, upper pressure attached oil cylinder 17, upper pressure attached oil cylinder Piston rod 18, hexagon socket screw 19, hexagon socket screw 20, lower heating plate 21, hexagon socket screw 22, retaining ring 23, main oil cylinder 24, plunger 25, oil inlet joint 26, lower heating plate 27, middle heat Plate 28, upper heating pole 29, hexagon socket head cap screw 30, hexagon socket cap screw 31, upper clamping heat plate 32, floating plate 33, lower pressure attac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com