Method of printing numerical code anti-fake label

A printing method and anti-counterfeit label technology, which is applied in the field of digital anti-counterfeit label printing, can solve the problems of being unable to combat anti-counterfeiting and anti-counterfeiting, and achieve the effect of being difficult to decipher

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

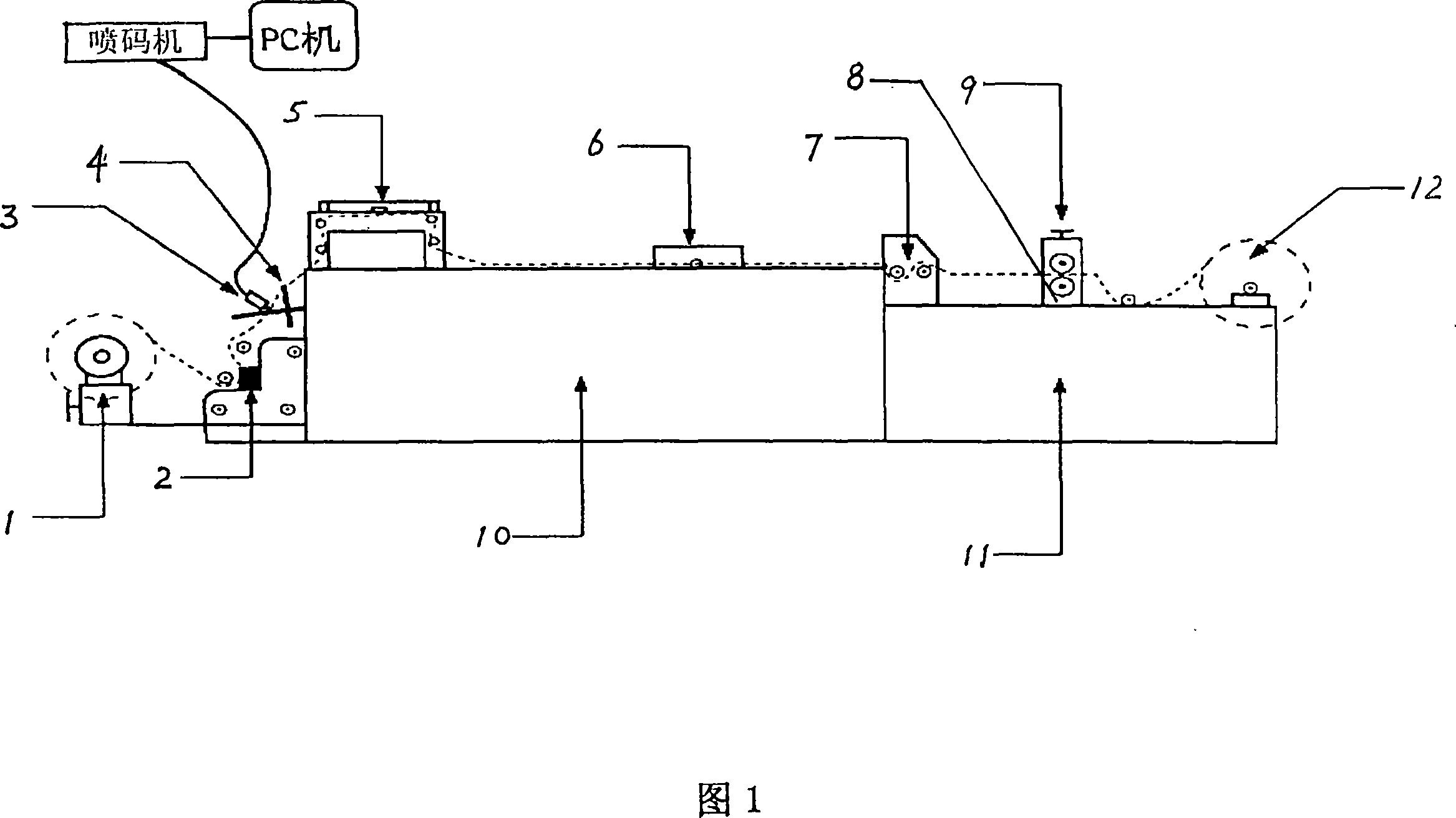

[0015] As shown in Figure 1, it is a schematic diagram of the structure of the palm-joining machine. The palm-joining machine is composed of an unwinding place 1, an EPC deviation correction device 2, an inkjet printer 3, a connecting bracket 4, a photoelectric sensor 5, a fan 6, a film guide roller 7, Rewinding traction main drive roller 8, synchronous encoder 9, main frame wallboard 10, the main engine tail wallboard 11 that has main drive motor inside and unwinding place 12 are formed.

[0016] A digital anti-counterfeiting label inkjet method is:

[0017] The first step. Modify the palm machine

[0018] On the side of the host wallboard 10 at the upper end of the EPC correction device 2, the inkjet printer 3 with a PC is installed through the connecting bracket 4, and the photoelectric printer 3 is installed on the upper end of the host wallboard 10 close to the inkjet printer 3 with the PC through the bracket. Inductor 5, a synchronous encoder 9 is installed on the windi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com