Optical diaphragm structure with light scattering and concentration function

An optical film and functional technology, applied in optics, optical components, instruments, etc., can solve the problems of overall cost, working hours, environmental waste, and vulnerability to scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the above-mentioned purpose, functional features, and advantages of the present invention more clearly understood, the present invention will be described in detail below with preferred examples and accompanying drawings.

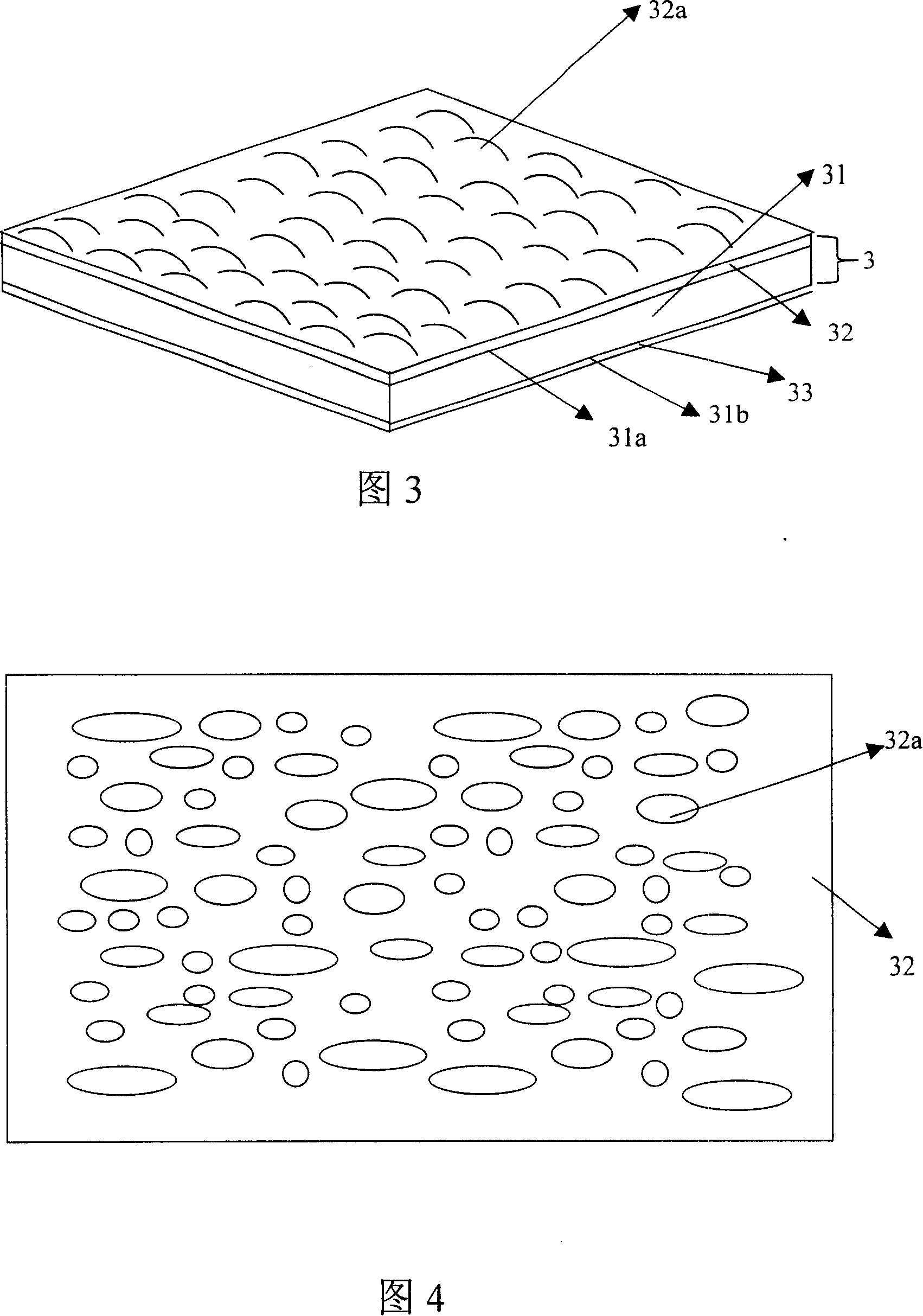

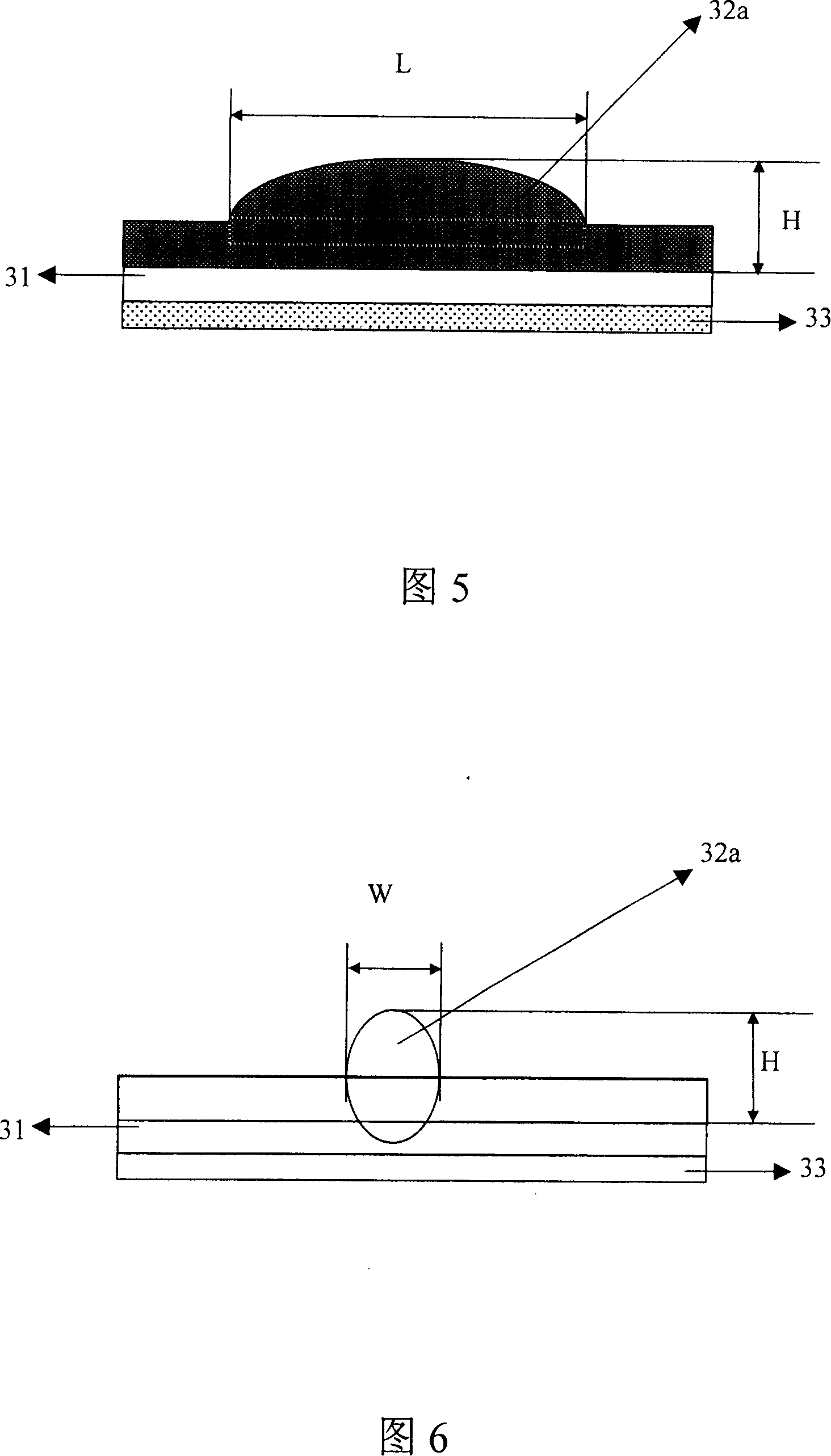

[0038] Please refer to Fig. 3 and shown in Fig. 4, the diffusion concentrating film 3 of the first embodiment of the present invention, it comprises a substrate 31, the diffusion concentrating layer 32 and an antistatic adhesive layer 33, the diffusion concentrating layer 32 It has a plurality of diffusing and concentrating units 32a.

[0039] The substrate 31 has an upper surface 31a and a lower surface 31b for light to pass through. The light-diffusing layer 32 can be formed by coating the surface of the base sheet 31 with UV-curable transparent polyester, and rolling a mold with a microstructure to form a plurality of light-diffusing units 32a. It is then produced by irradiating ultraviolet (UV) rays to produce polymerization and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com