Surface light source apparatus, optical conductor used therefor and its manufacturing method

A technology of light guide body and surface light source, applied in the field of light guide body, can solve the problem of obvious uneven brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~11、 comparative example 1~5

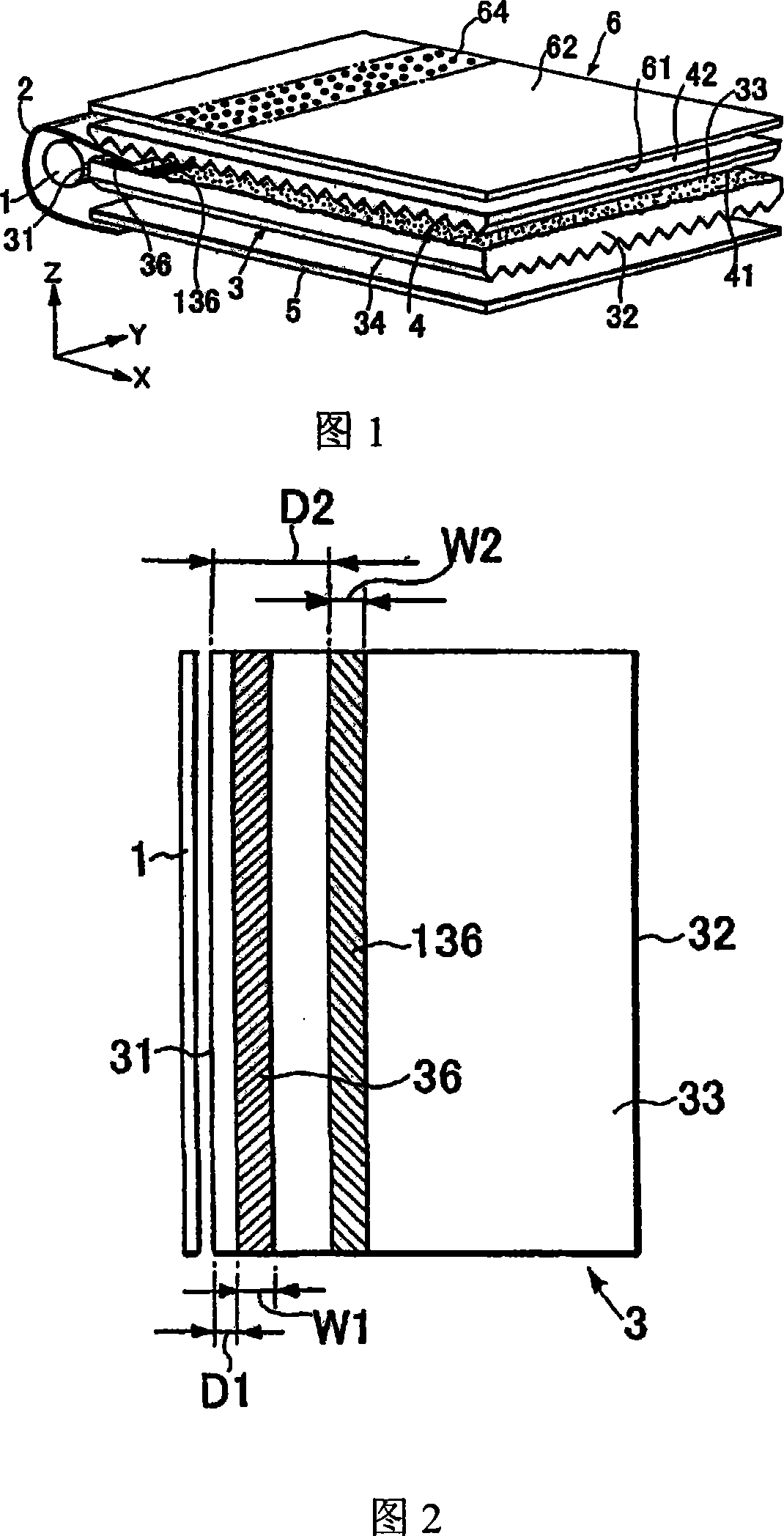

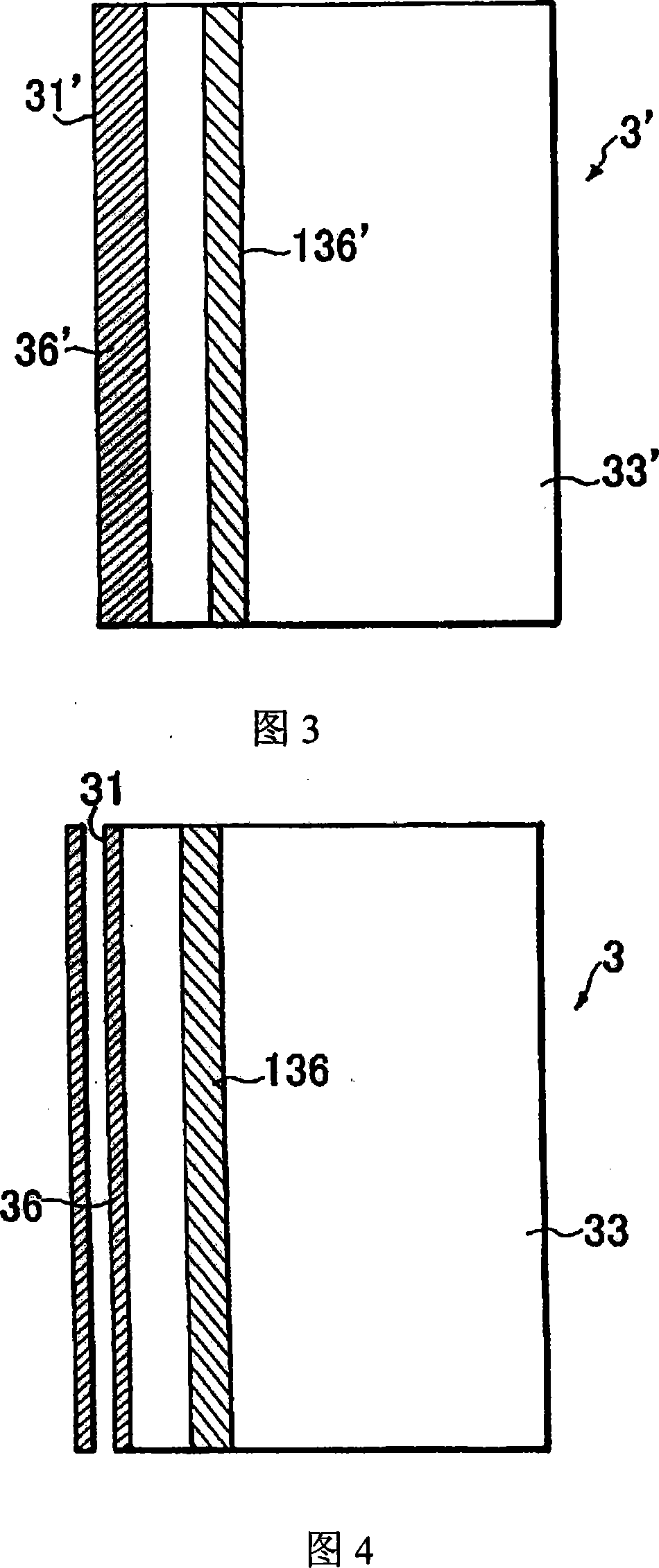

[0456] Using acrylic resin (ACRYPET (trade name) manufactured by Mitsubishi Rayon Co., Ltd.) by injection molding, a rectangular and wedge-shaped light guide material is produced. One side of the material is rough, and the other side is a prism corner. A prism column with 100 degrees, a top tip curvature radius of 15 μm, and a pitch of 50 μm. The prism column is a prism pattern continuously arranged parallel to the short side. The black ink described below was applied by screen printing to various widths (Examples 1 to 11, Comparative Examples 1 to 5) from the thicker long side on the rough surface of the light guide material on which the prism pattern was formed. A portion corresponding to the first light absorption band is formed. When the black ink was printed on a transparent acrylic plate with a thickness of 2 mm in the same manner as the visible light transmittance, the visible light transmittance of the ultraviolet curable black ink was 30%. Simultaneously, a second li...

Embodiment 8

[0472] Embodiment 8——W1=300 μm, D2=900 μm, W2=300 μm

Embodiment 9

[0473] Embodiment 9——W1=300 μm, D2=900 μm, W2=150 μm

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com