Steel ball free simulated antitank grenade for training

A technology of simulating hands and steel balls, which is applied in the direction of practicing ammunition, weapon accessories, ammunition, etc., can solve the problems of high cost, difficult training effect, casualties, etc., and achieve the effect of simplifying structure and materials, avoiding casualties, and operating realistically

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

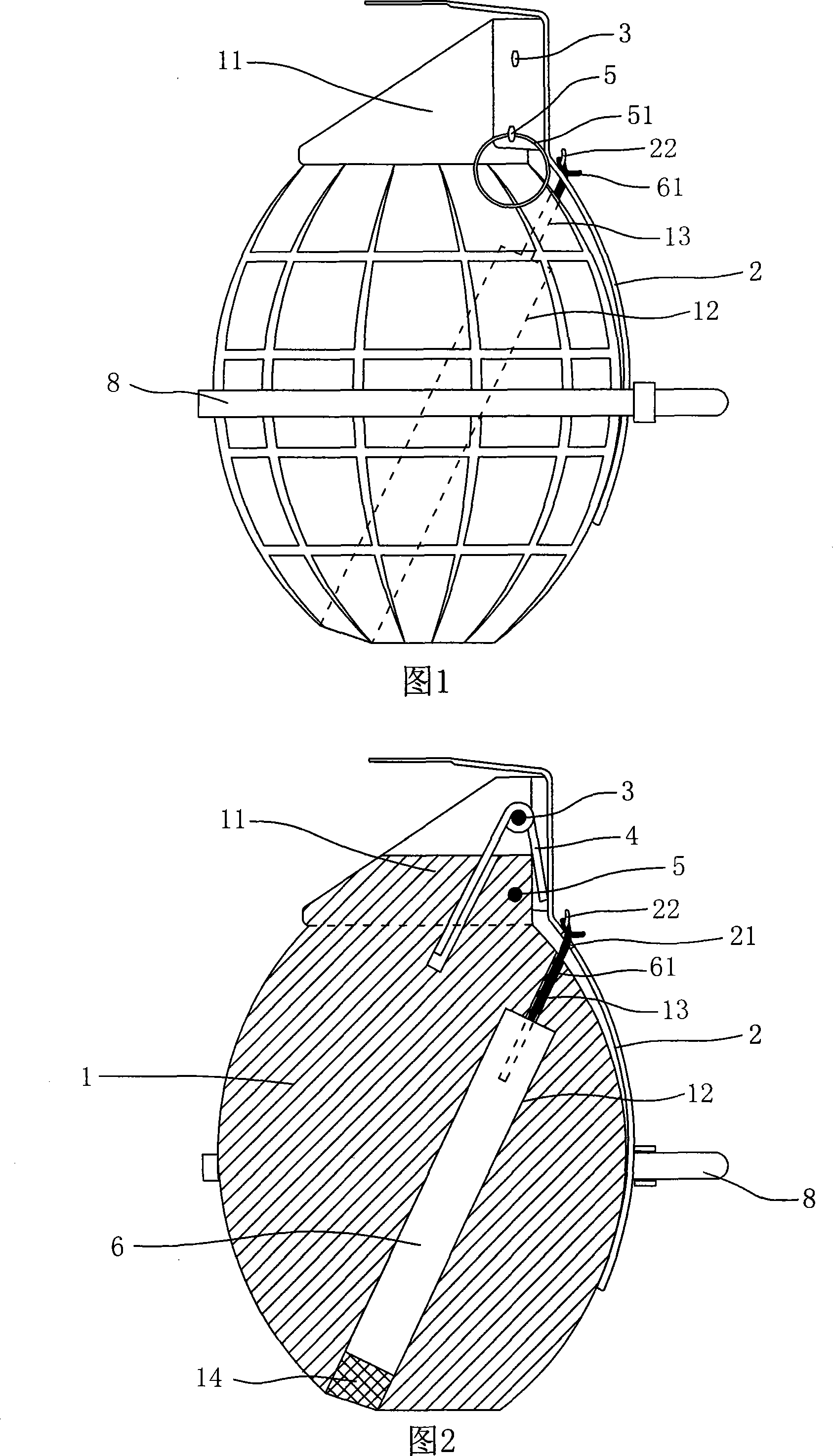

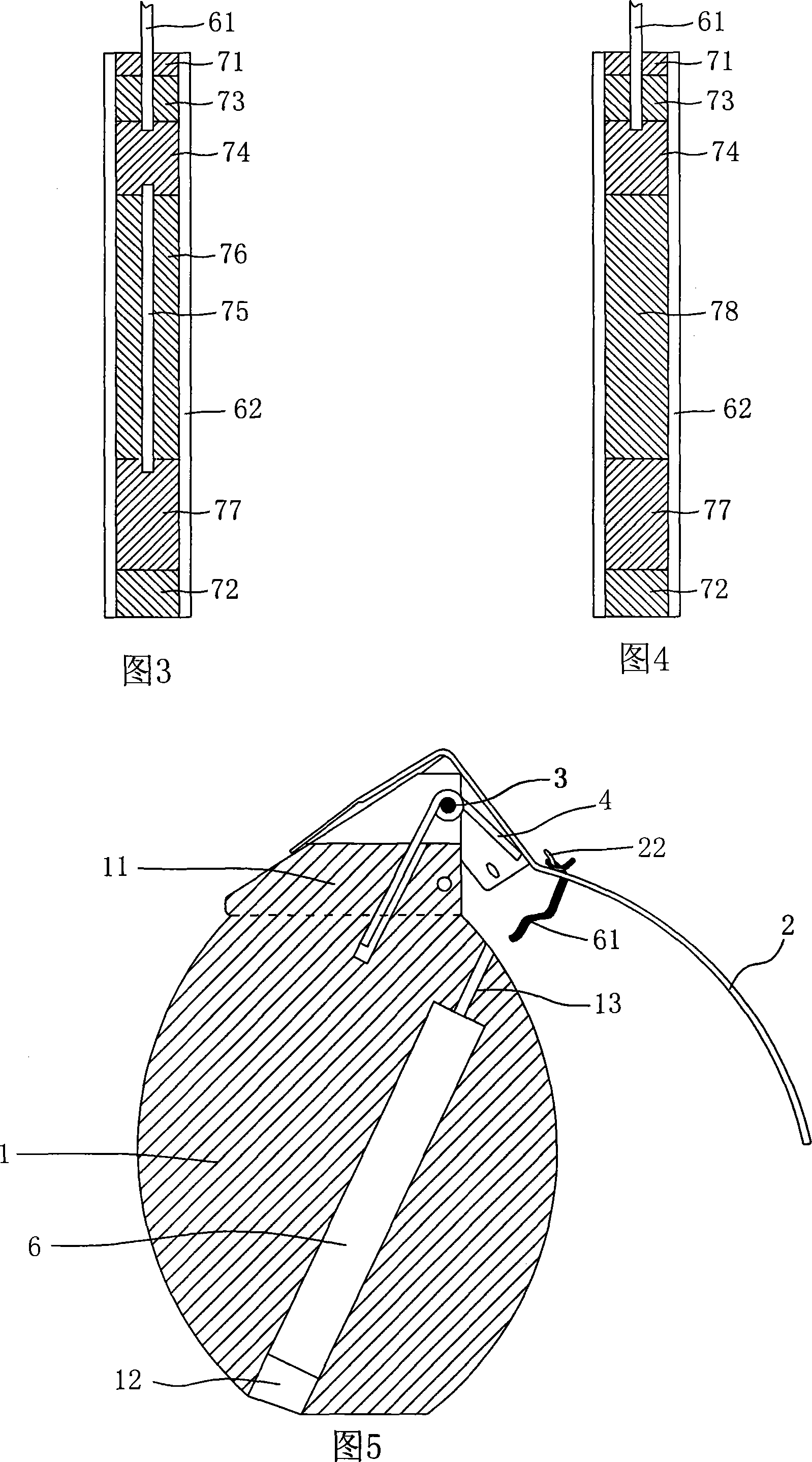

[0017] Embodiment 1: With reference to Fig. 1, Fig. 2. The top of the lightning shell 1 is connected with a mounting base 11, and the mounting base 11 is integrally formed with the lightning shell 1. The safety plate 2 is installed on the mounting seat 11 through the torsion spring shaft pin 3, the torsion spring 4 is sleeved in the middle of the shaft pin 3, and the torsion spring 4 is pressed between the lightning shell 1 and the safety plate 2 of the mounting seat. Insert safety pin 5 with pull ring 51 between mounting base 11 and safety plate 2, overcome torsion spring 4 torques by safety pin 5, make safety plate 2 hand-holding end when stand-by be close to thunder shell 1 side surface. The appearance, weight and feel of Thunder Shell 1 are basically the same as those of real guns, and it can be made of solid rubber or plastic; things. Insurance sheet 2 adopts steel plate to make.

[0018] Refer to Figure 2. Thunder shell 1 is internally provided with accommodating hol...

Embodiment 2

[0022] Embodiment 2: Refer to Fig. 4 . The difference between this embodiment and Embodiment 1 is that the delayed detonator of the sound detonation device 6 adopts a delayed detonation agent 78, and the delay detonation agent 78 is filled between the ignition agent 74 and the sound explosion agent 77, rather than the embodiment. 1 The fuse used. Delayed detonating agent 78 separates igniting agent from loud explosive agent, and after ignition agent 74 is ignited, it delays by delaying the detonating agent 78 to cause the explosion of loud explosive agent. The rest of the structure is the same as that of Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com