Outer rotor fan type fully ventilating biology safety cabinet

A technology of external rotor fans and biological safety cabinets, applied in the direction of heating methods, ventilation systems, shells or chambers, etc., can solve problems such as difficulty in negative pressure envelopment, uneven airflow, large vibration, etc., to meet high-standard technical requirements, The effect of comprehensive performance improvement and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

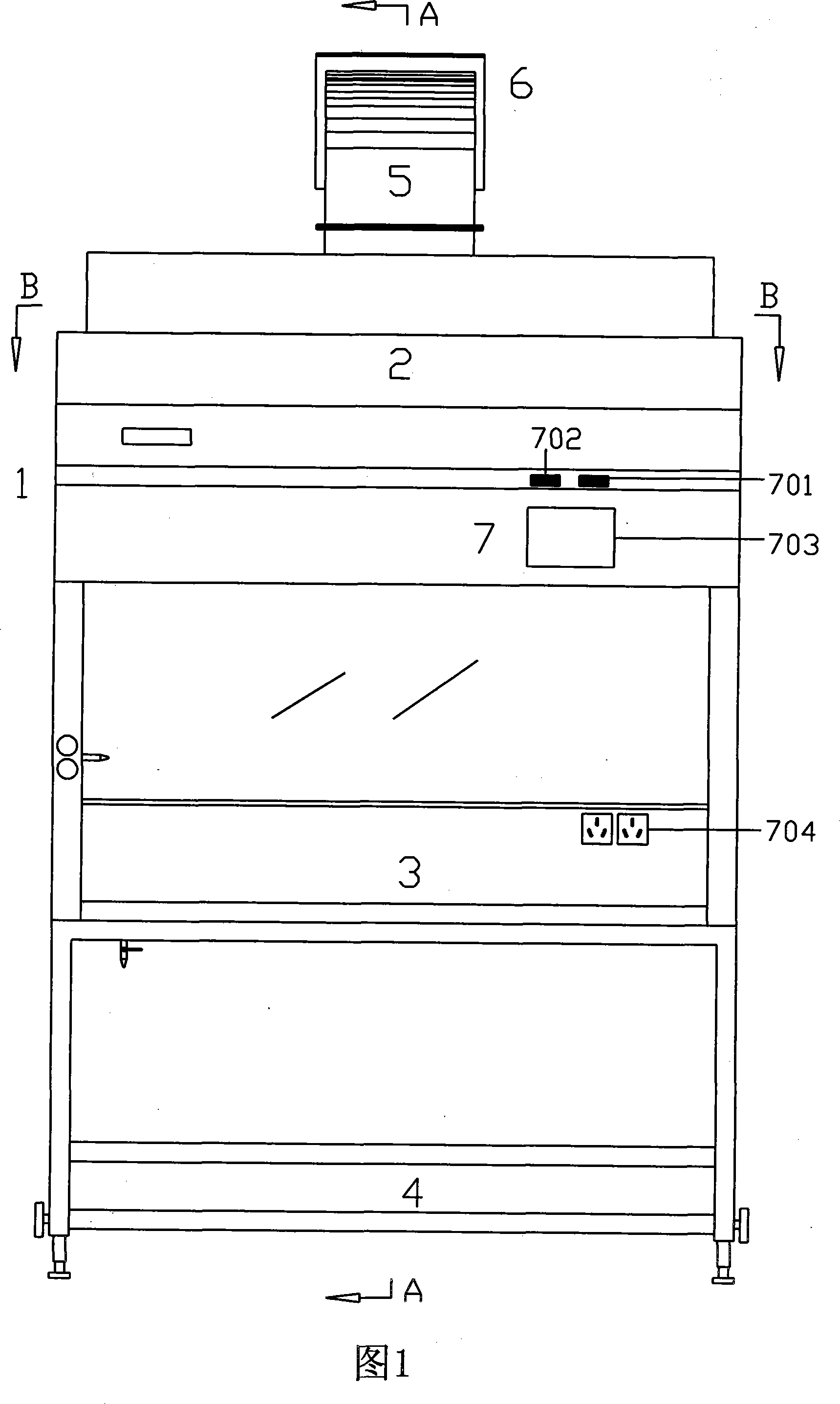

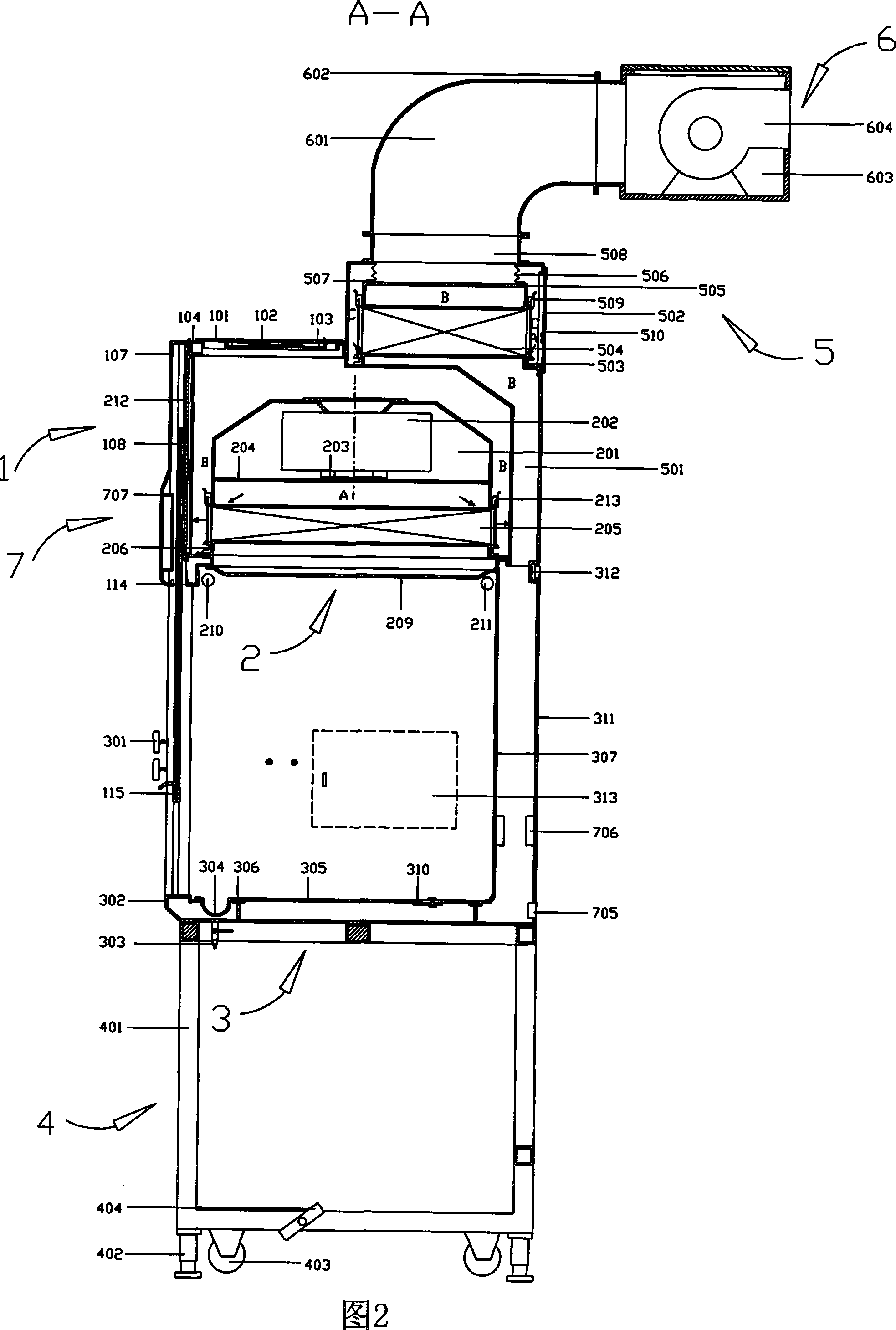

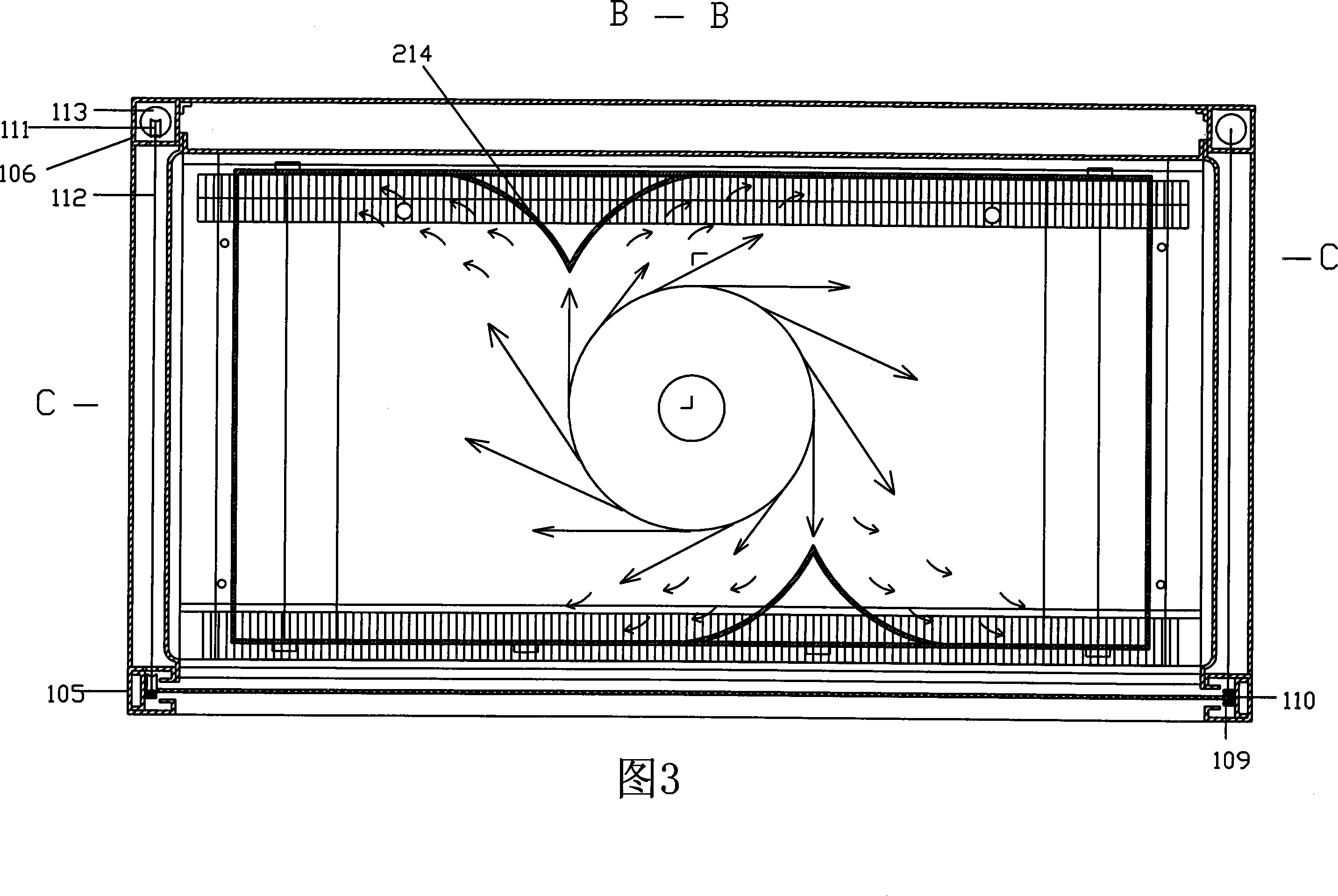

[0028] Referring to Fig. 1, Fig. 2, Fig. 3, and Fig. 4, an external rotor fan-type full-exhaust biological safety cabinet mainly consists of an upper cabinet body part 1, a purification work area part 2, an operating table part 3, and a support part 4 , negative pressure package part 5, exhaust part 6, electrical control part 7 and other components, the exhaust part 6 is an auxiliary accessory of the biological safety cabinet; the upper cabinet part 1 is installed on the bracket part 4 and fixed by hexagon socket bolts ; The upper part of the upper part of the upper cabinet part 1 is the purification work area part 2, and the upper part is equipped with a negative pressure bag part 5, the lower part of the upper part of the cabinet part 1 is the operating table part 3, and the electrical control part 7 is located in the upper part of the cabinet body 1 and the inside of the purification work area part 2, the exhaust part 6 is installed outside the upper cabinet part 1, and comm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com