Electrostatic discharge detection device and method

An electrostatic discharge test and electrostatic technology, which is applied in the direction of measuring devices, measuring electricity, measuring electrical variables, etc., can solve problems such as product malfunction, labor consumption and testing man-hours, and inability to directly find problems with electronic components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

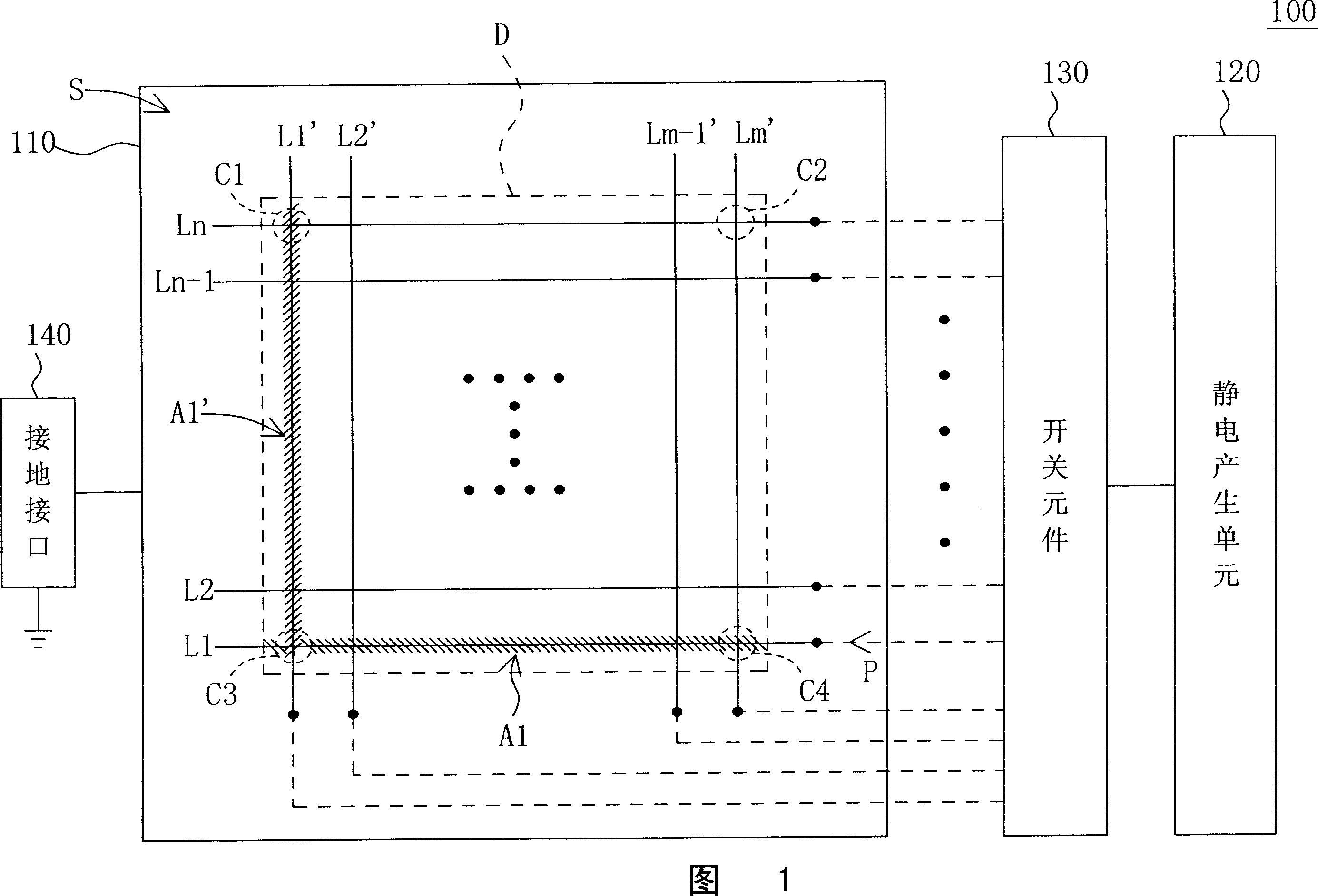

[0015] Please refer to FIG. 1 , which is a schematic diagram of an electrostatic discharge testing device according to a first embodiment of the present invention. The electrostatic discharge testing device 100 includes a testing platform 110 , a static electricity generating unit 120 , a switch element 130 , and a grounding interface 140 , wherein the testing platform 110 is provided with a plurality of wires.

[0016] The above-mentioned test platform 110 is coupled with the ground interface 140 so that the test platform 100 is grounded, that is, the test platform 110 can introduce its accumulated electrostatic charge into the ground terminal through the ground interface 140, so as to avoid the test platform 110 from being repeatedly input by static electricity. Pulse P and accumulate too much static electricity, resulting in the user may be endangered.

[0017] The switch element 130 is respectively coupled to the wires of the test platform 110 and the static electricity ge...

no. 2 example

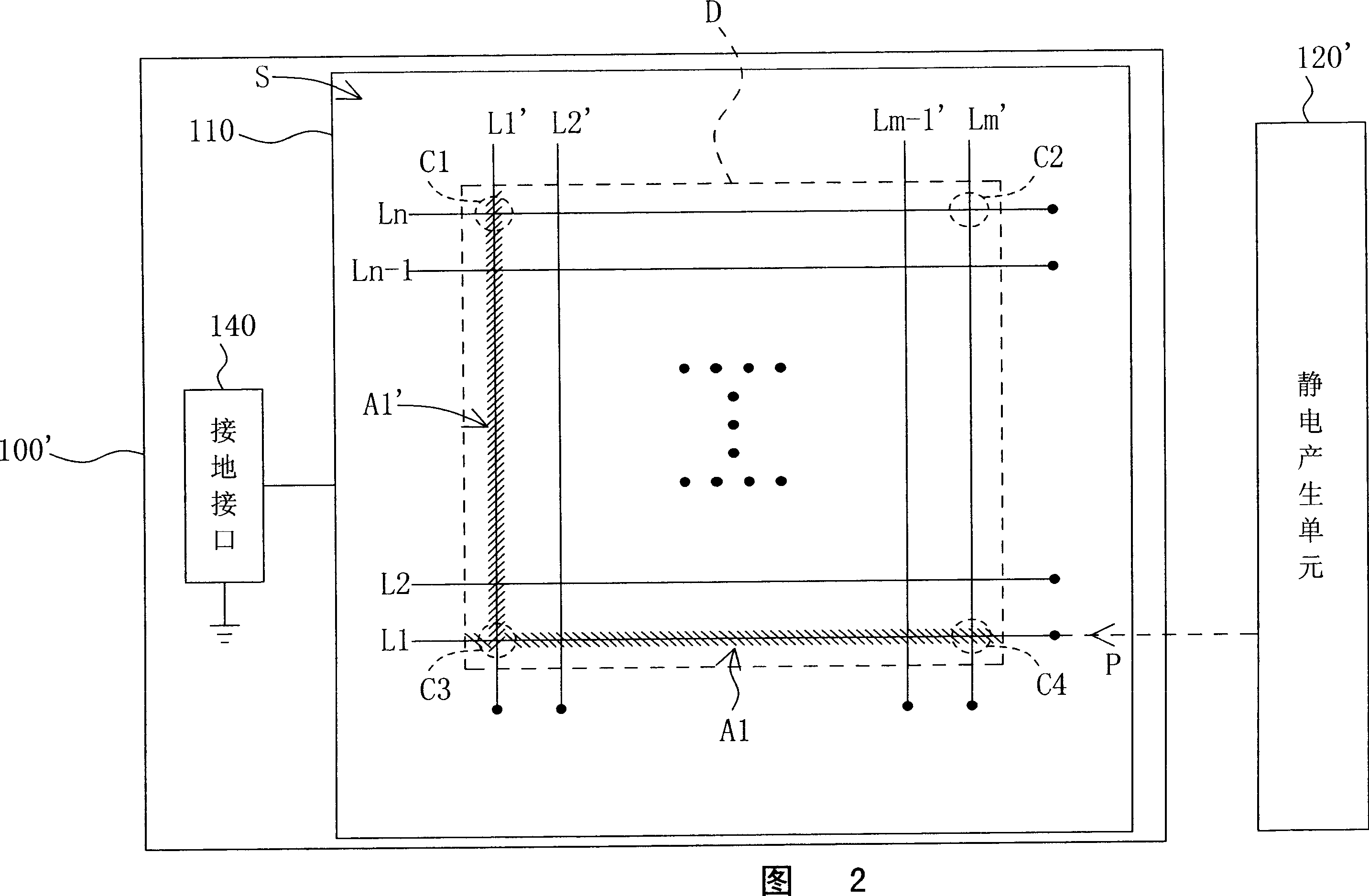

[0028] Please refer to FIG. 2 , which is a schematic diagram of an electrostatic discharge testing device and a static electricity generating unit according to a second embodiment of the present invention. This embodiment is similar to the above-mentioned first embodiment, but the ESD testing device 100' in this embodiment does not use a switching element. In this embodiment, the electrostatic generating unit 120' uses an electrostatic gun as an electrostatic discharge device. In this way, when the tester intends to perform an electrostatic discharge test, he can selectively contact the static electricity generating unit 120' with one of the wires L1-Ln and L1'-Lm', and provide an electrostatic pulse P to the wire (such as The first wire L1 of FIG. 2).

[0029]The difference between this embodiment and the above-mentioned first embodiment is that the static electricity generating unit 120 in the first embodiment can automatically and respectively provide static electricity pu...

no. 3 example

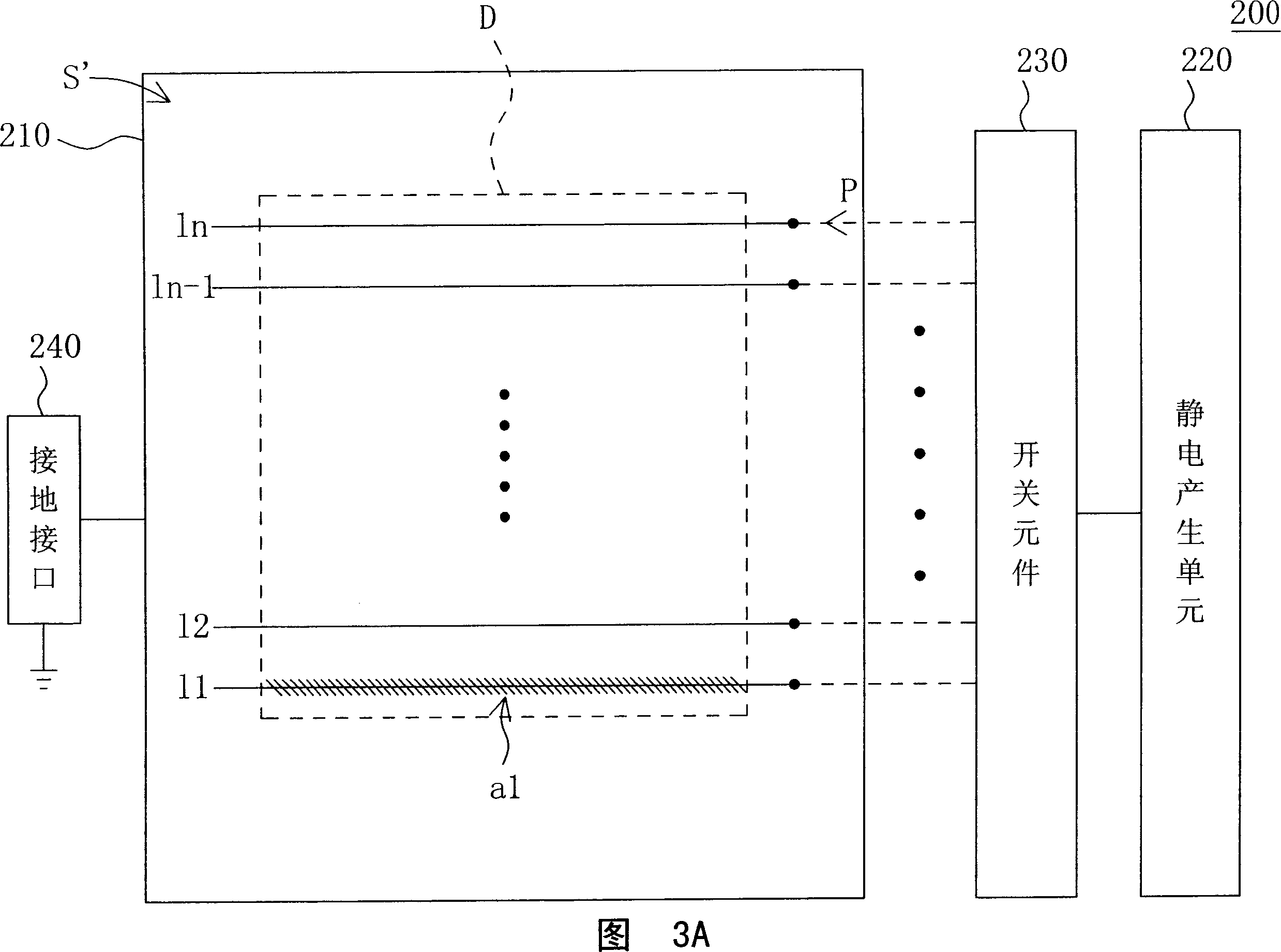

[0031] Please refer to FIGS. 3A and 3B . FIG. 3A is a schematic diagram of an electrostatic discharge testing device according to a third embodiment of the present invention, and FIG. 3B is a schematic diagram of another placement angle of the object D in FIG. 3A . The difference between the third embodiment and the first embodiment is that the test platform 210 of the electrostatic discharge testing device 200 only lays out the first horizontal wires l1˜ln.

[0032] At this time, the test of the first embodiment is performed with the placement angle of the object D shown in FIG. 3A . After testing the first conductive wires l1-ln with the electrostatic pulse P, for example, it is obtained that the area a1 corresponding to the first conductive wire l1 in the object under test D contains the test failure object. At this time, the user can rotate the object D to be tested by a preset angle, such as 90 degrees clockwise, so that the relative positions of the first wires l1-ln and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com