Gravity-assisted steam flooding exploitation method for heavy laver common heavy oil reservoir

A heavy oil reservoir, auxiliary steam technology, applied in the direction of production fluid, earthwork drilling, wellbore/well components, etc., can solve the problems of low production efficiency, high drilling investment and steam injection cost, and achieve improved coverage and improved The effect of oil recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

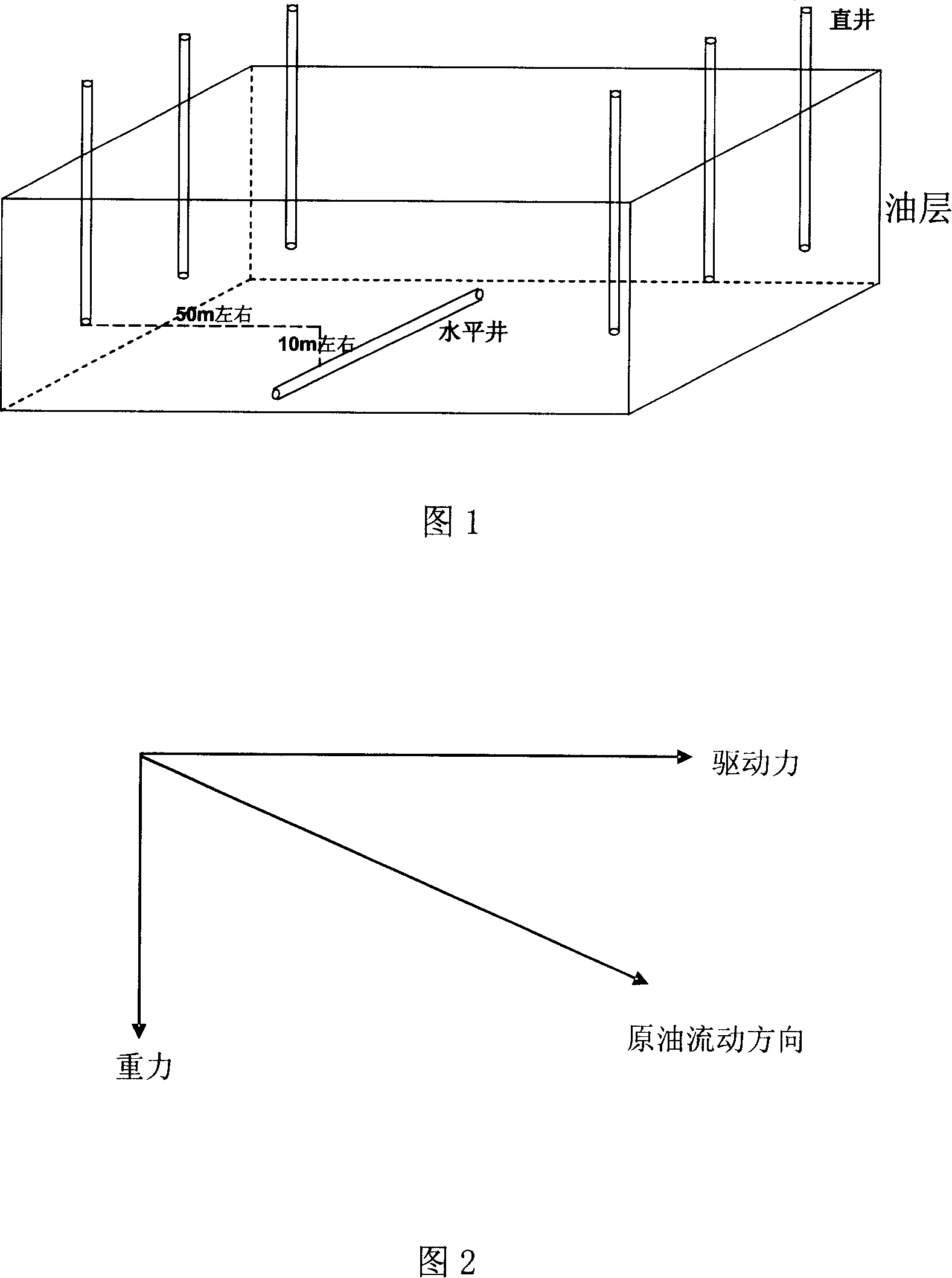

[0035] Example 1: The sand body of oil layer 6 in an oilfield is a thick massive ordinary heavy oil reservoir, the viscosity of degassed crude oil at 50°C is 2284.2mPa·s, and the average thickness of the oil layer is 38.89m. The vertical well steam huff and puff has been used in this reservoir for an average of 7 cycles, the formation pressure has dropped from the original value of 16.1MPa to 1.0MPa, and the cycle oil production and oil-gas ratio have decreased. According to the geological characteristics, crude oil properties and development status of the reservoir, gravity-assisted steam flooding technology combined with vertical wells and horizontal wells was adopted.

[0036] (1) Perform rough screening according to reservoir geological parameters and fluid characteristics;

[0037] (2) The thickness of the continuous oil layer is greater than 15m, the porosity is greater than 20%, the permeability is greater than 500md, and the ratio of vertical permeability to horizontal...

example 2

[0043] Example 2: The oil layer of the third member of the east of an oilfield is a thick block ordinary heavy oil reservoir, the viscosity of degassed crude oil at 50°C is 7478mPa·s, and the average thickness of the oil layer is 22m. The vertical well steam huff and puff has been used in this reservoir, and the average has reached 6 cycles. The formation pressure has dropped from the original value of 12.6MPa to 3.0MPa, and the cycle oil production and oil-gas ratio have decreased. According to the geological characteristics, crude oil properties and development status of the reservoir, gravity-assisted steam flooding technology combined with vertical wells and horizontal wells was adopted.

[0044] (1) Perform rough screening according to reservoir geological parameters and fluid characteristics;

[0045] (2) The thickness of the continuous oil layer is greater than 15m, the porosity is greater than 20%, the permeability is greater than 500md, and the ratio of vertical perme...

example 3

[0051] Example 3: The third member of the Shahejie Formation in an oilfield is a thick massive ordinary heavy oil reservoir, the viscosity of degassed crude oil at 50°C is 3500mPa·s, and the average thickness of the oil layer is 54m. The reservoir is buried at a depth of 1300m, the original reservoir pressure is 13.4MPa, and the original reservoir temperature is 52°C. According to the geological characteristics and crude oil properties of the reservoir, the gravity-assisted steam flooding technology of horizontal well and horizontal well combination was adopted.

[0052] (1) Perform rough screening according to reservoir geological parameters and fluid characteristics;

[0053] (2) The thickness of the continuous oil layer is greater than 15m, the porosity is greater than 20%, the permeability is greater than 500md, and the ratio of vertical permeability to horizontal permeability is greater than 0.2, which is suitable for gravity-assisted steam flooding;

[0054] (3) For und...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Permeability | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com