Straight liquid type writing item component and pen with the same

A direct liquid type, component technology, applied in writing instruments, ink pens with ink storage tubes in the pen, ball-point pens, etc. The effect of long service life, accelerated breadth development and popularization, and low synthesis cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

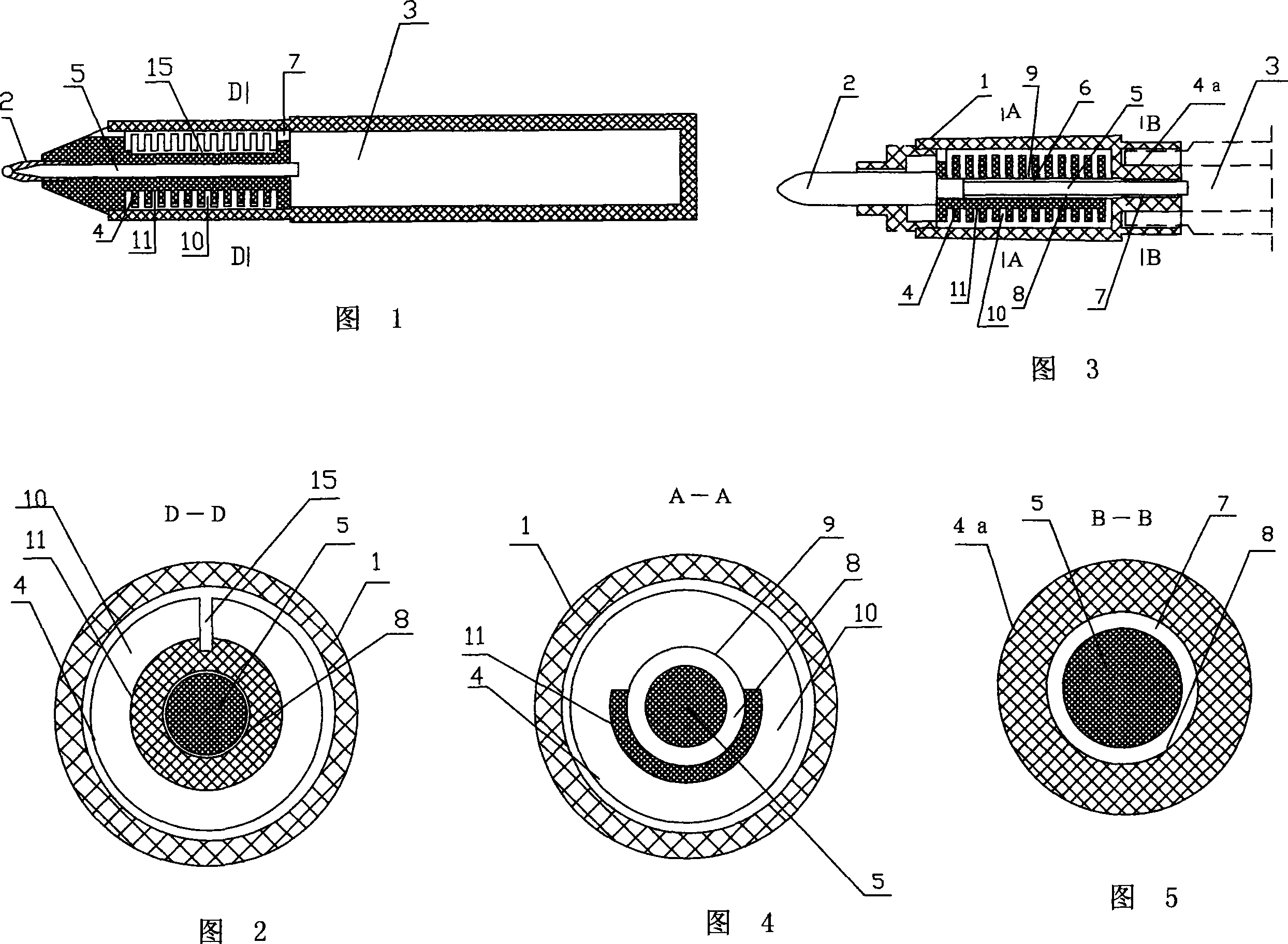

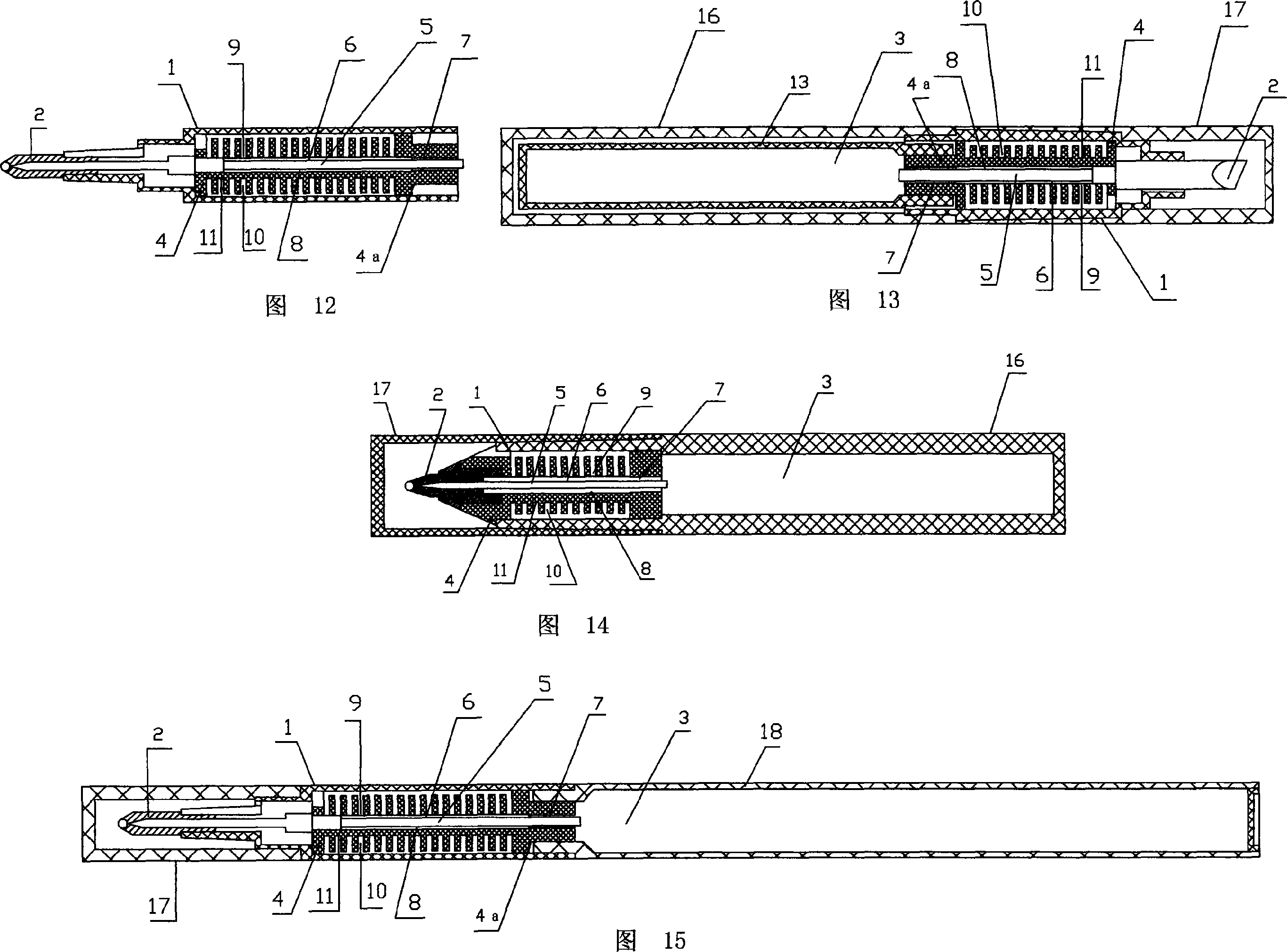

[0039] As shown in Fig. 3, Fig. 4 and Fig. 5, the direct liquid type writing item assembly consists of a pen item 1 and a nib 2 arranged at the front end of the pen item 1. The ink chamber 3 located at the rear end of the pen item 1; the water diversion part 5 extending axially between the above-mentioned nib 2 and the ink chamber 3 is arranged, and several ring grooves 10 and the bottom surface of the ring groove are arranged on the inner and outer peripheral parts of the pen item 1 11 water reservoirs (4); the central part of the pen item 1 water reservoir 4 is provided with a central hole 8 that can pass through the water diversion part 5, between the water diversion part 5 outer surface and the central hole 8 inner surface of the pen item 1 A valve channel 7 is provided between them; a notch 9 directly connected with the central hole 8 is formed on the bottom surface 11 of the annular groove 10 of the water reservoir 4; a transition channel 6 is provided on the side of the ...

Embodiment 2

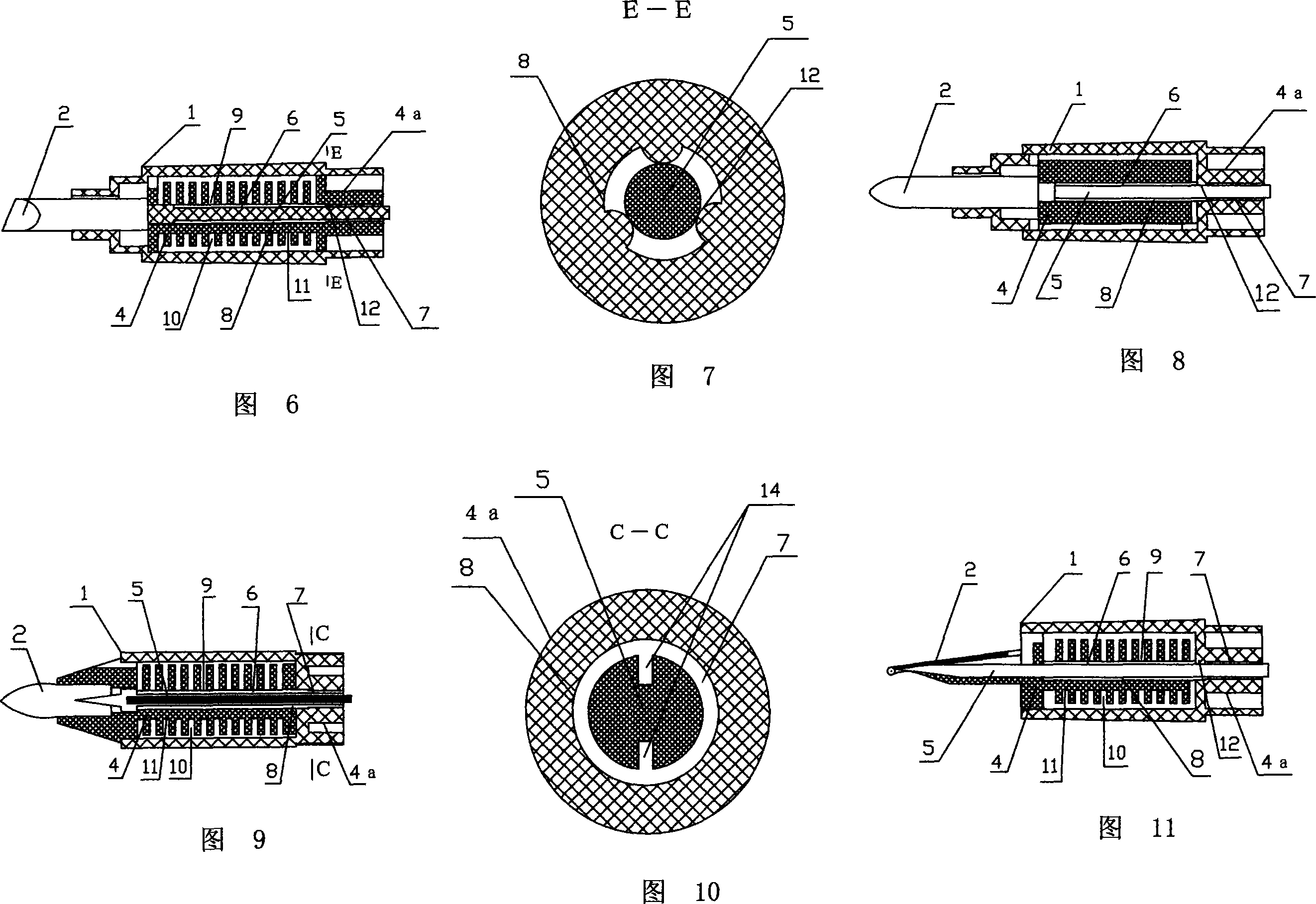

[0045] As shown in Figure 6 and Figure 7, the direct liquid type writing item assembly, compared with Figure 3 Example 1, is different in that (1) the valve channel 7 is located on the inner surface of the central hole 8 of the water reservoir 4 and the water diversion part 5 Between the outer surfaces; (two) the shape of the nib 2, the parameters of the ink outlet system and the size of the gap of the air passage 7 matched with the ink outlet system parameters; (three) the water storage at the water diversion part 5 by the ink chamber 3 one end The outer periphery of the center hole 8 of the device 4 is provided with a matching section 4a closely matched with the outlet of the ink chamber 3; Evenly distributed. (5) The nib 2 of the present embodiment is a highlighter nib; the nib 2 and the water diversion part 5 are all made of chemical fiber material of a plastic body. (6) When assembling, the water storage device 4 is first pressed in from the rear of the pen item 1, and t...

Embodiment 3

[0048] As shown in Figure 8, the direct liquid type writing item assembly, compared with Figure 3 Embodiment 1, is different in that (1) the water reservoir 4 is made of a columnar porous material, and the water reservoir 4 peripheral parts The ink storage space is replaced by the multi-porosity that communicates with each other and communicates with the center hole; (2) a convex body 12 is provided in the center hole 8 of the pen item 1, so that the gap of the air valve passage is evenly distributed.

[0049] The rest of the implementation manners are similar to those in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com