Hydrogen generation device, operation method thereof, and fuel cell system

A technology for generating devices and fuels, which is applied to fuel cells, fuel cell additives, fuel cell heat exchange, etc., and can solve the problems of ineffective hydrogen generation devices, poor economy, and reduced hydrogen generation efficiency, and achieves start-up time and Start-up characteristics, high reliability and economy, stable effect of modified reaction characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

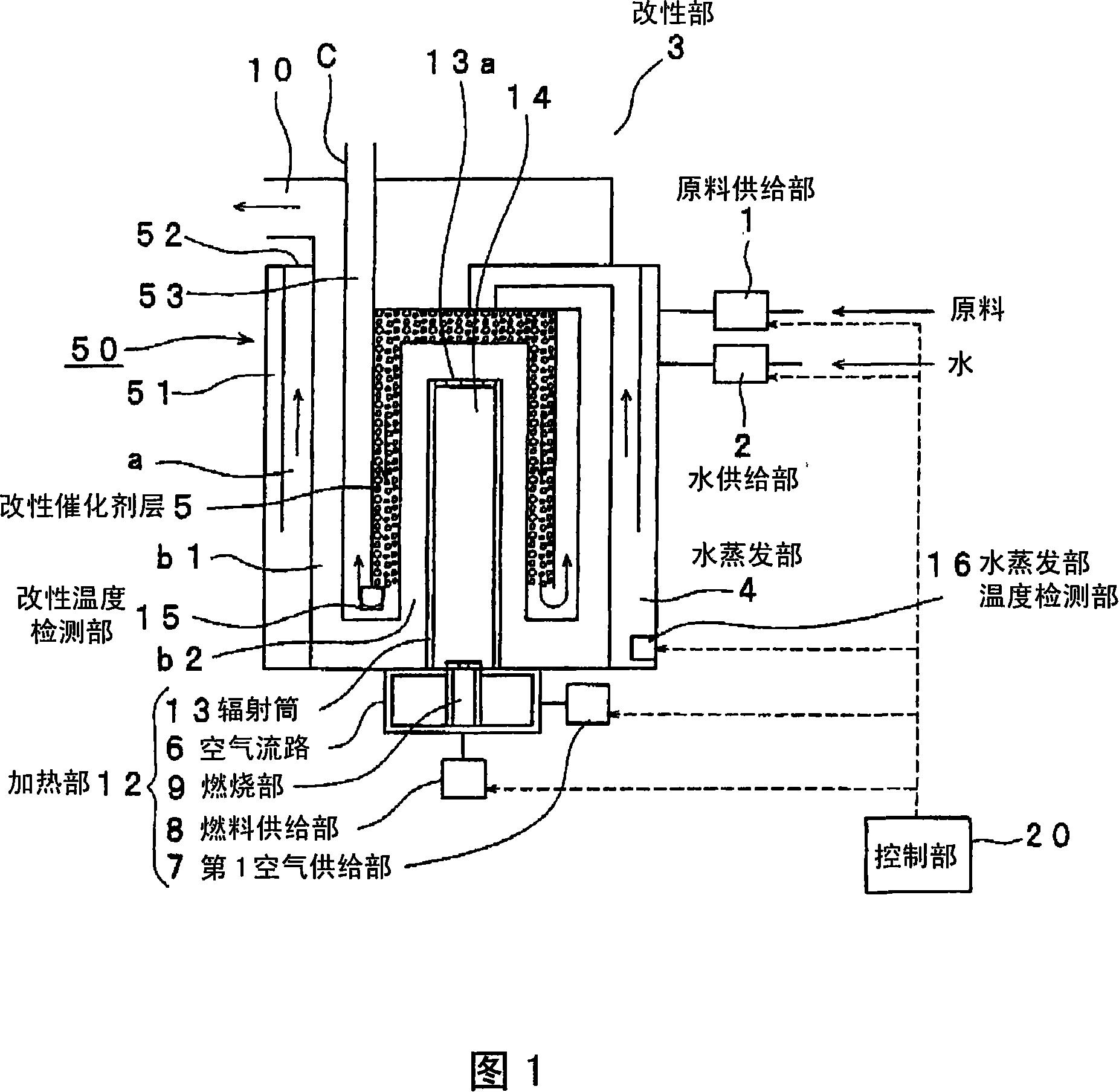

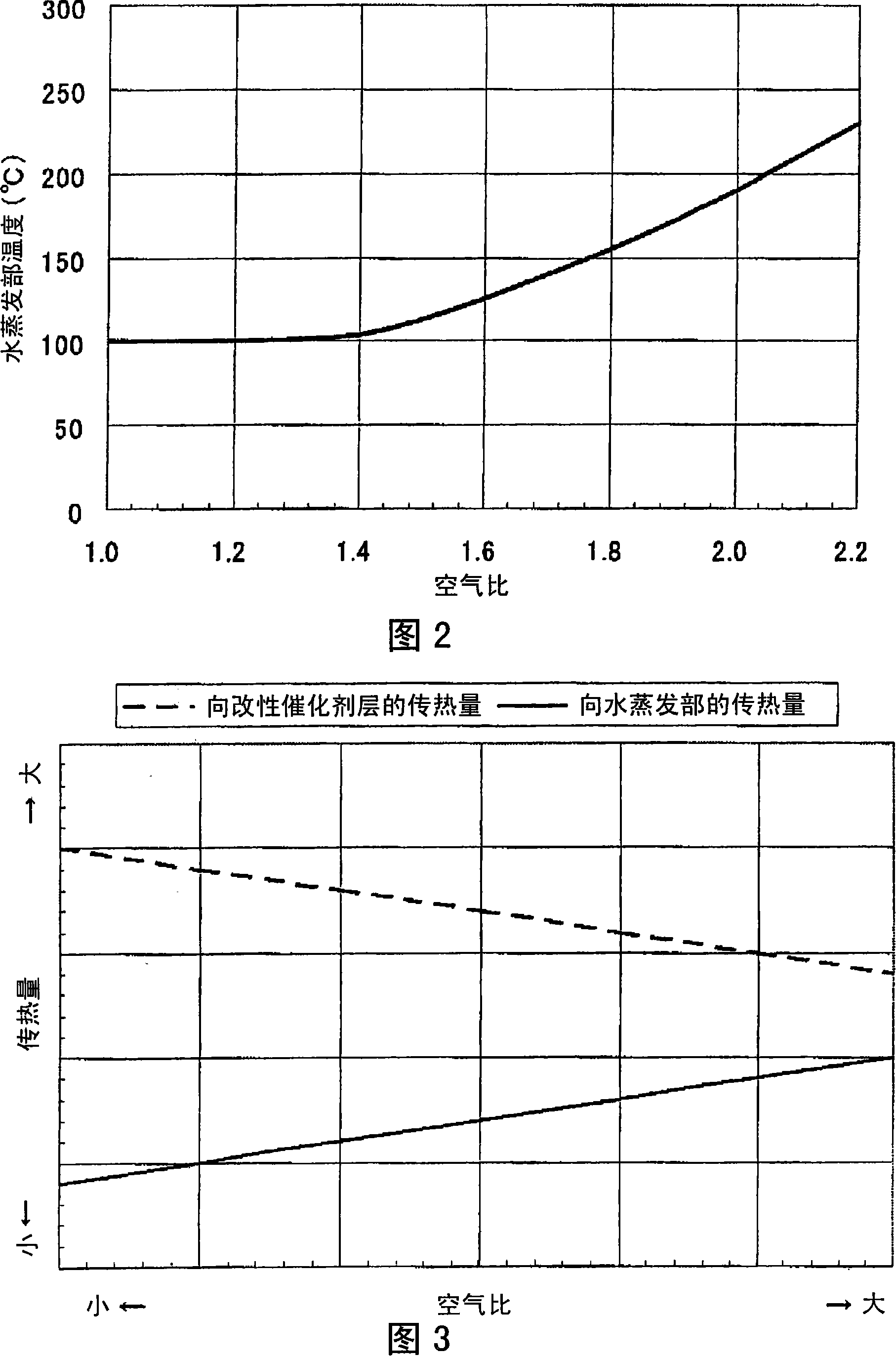

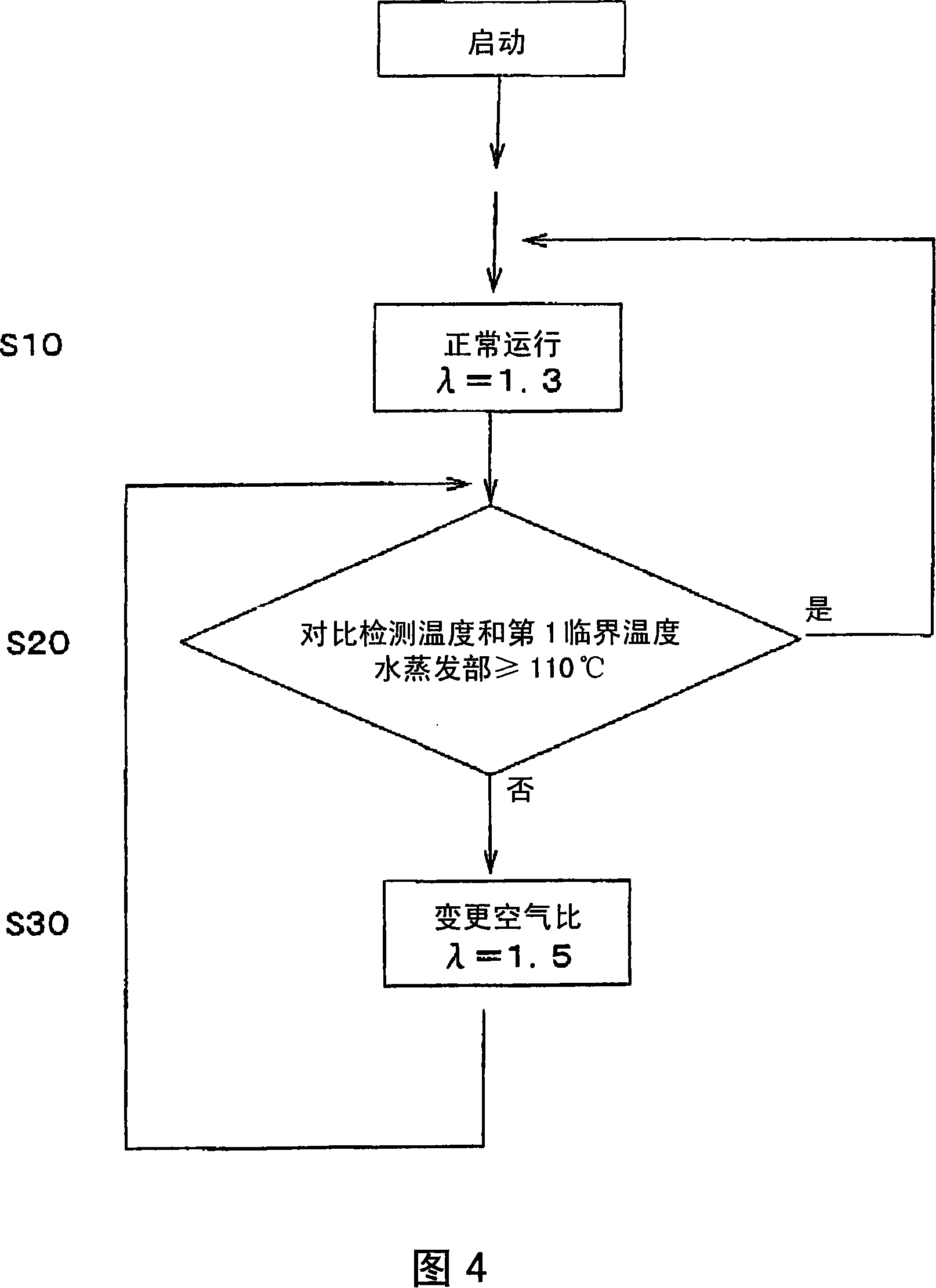

[0040] 1 is a schematic cross-sectional view showing the configuration of a hydrogen generator according to Embodiment 1 of the present invention, and particularly shows in detail the configuration of a reforming unit which is a main component of the hydrogen generator. As shown in FIG. 1 , the hydrogen generator is composed of a cylindrical body 50 with its upper end and lower end closed, and is equipped with a reforming device for steam reforming a raw material containing at least an organic compound composed of carbon and hydrogen to generate a hydrogen-containing gas. Section 3; water evaporation section 4 that supplies water vapor to the reforming section 3; temperature detection section 16 for the water evaporation section that detects the temperature of the water evaporation section 4 (hereinafter referred to as the temperature detection section); fuel and air are combusted, and The heating part 12 and the control part 20 are supplied to the heating part 12 and the contr...

Embodiment approach 2

[0062] The hydrogen generator related to this embodiment has the same function as that of Embodiment 1 except that the control unit has a function of judging whether or not water has started to accumulate in the water evaporator based on a threshold value composed of a time-varying value of the detected temperature instead of the critical temperature. constitute.

[0063] For example, when the detection temperature of the water evaporator 4 is 130°C, when the time change value ΔTw of the detection temperature is -1.0 deg / min, liquid water will not accumulate even after 10 minutes, but the ΔTw is -2.0 deg / min It only takes 5 minutes for water to start accumulating. In addition, when the detection temperature is 120°C, when the time change value of the detection temperature ΔTw is -0.5deg / min, liquid water will not accumulate even after 10 minutes, but it only takes 5 minutes when the ΔTw is -1.0deg / min It started to accumulate water.

[0064] Therefore, in the operating metho...

Embodiment approach 3

[0070] In the hydrogen generator related to this embodiment, when the control unit judges that the water evaporator has started to accumulate water, the amount of liquid water is not increased by evaporating the liquid water. It has the same structure as Embodiment 1 except for the function of controlling the amount of fuel in the fuel tank.

[0071] It is assumed that a normal operation is performed with a predetermined amount of fuel, for example, 1.5 NLM. When the detected temperature of the water evaporator 4 is below the critical temperature, for example, 110° C., the control unit 20 increases the amount of fuel supplied from the fuel supply unit 8 . When city gas 13A is supplied as fuel, the predetermined value 1.5NLM is increased by 0.2NLM to become 1.7NLM. On the other hand, when the detected temperature is 110° C. or higher, the fuel amount is returned to the predetermined flow rate of 1.5 NLM.

[0072] FIG. 7 is a graph showing the temperature of the water evaporat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com