Test method of sample destroy time in tube of glass fibre reinforced plastic long-term performance test

A glass steel pipe, long-term performance technology, used in measuring devices, strength characteristics, instruments, etc., can solve problems such as inability to obtain accurate time, destroying time errors, and consuming a lot of manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] A test method for the failure time of a sample in a long-term performance test of a glass steel pipe, which includes the following steps:

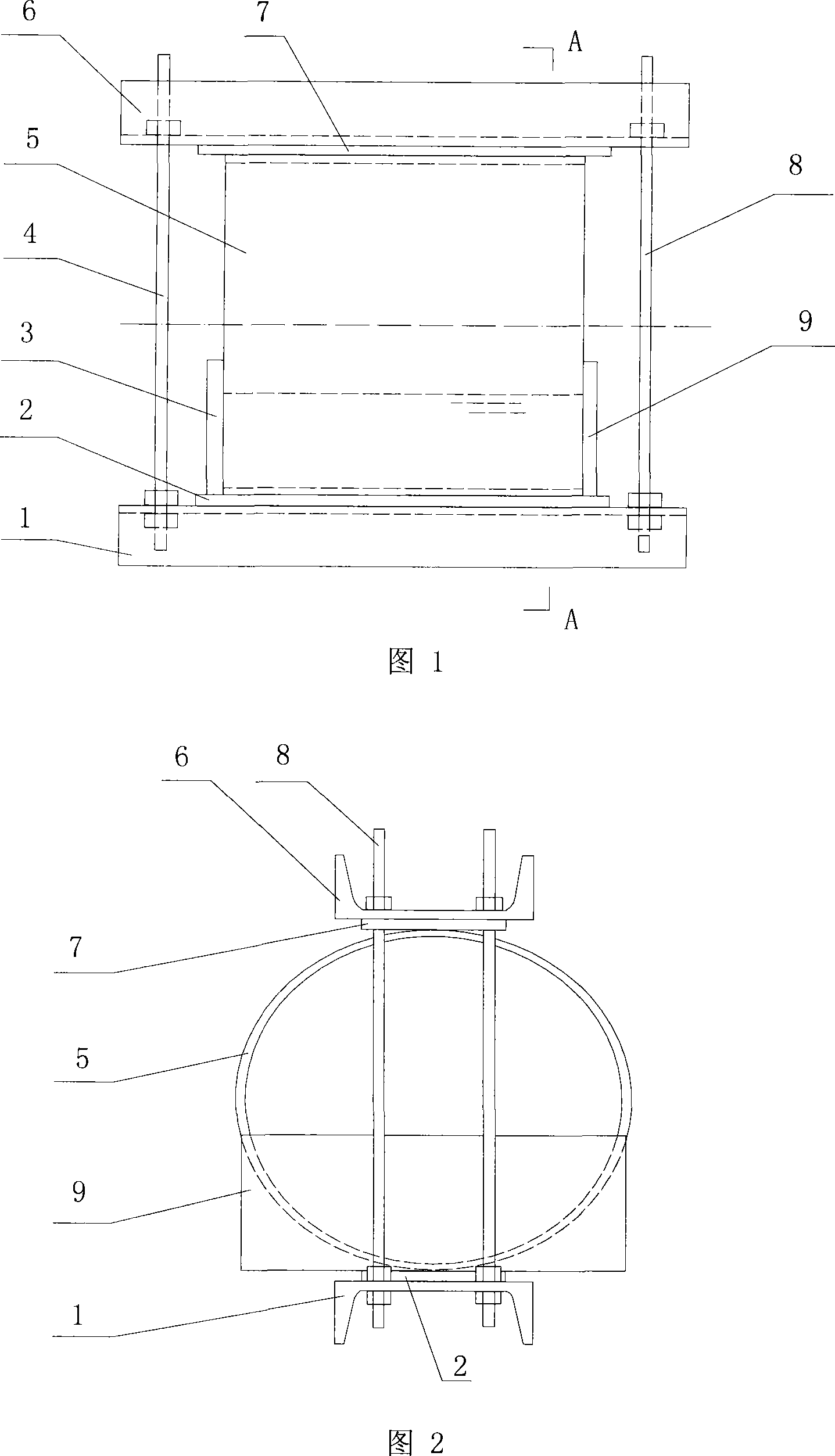

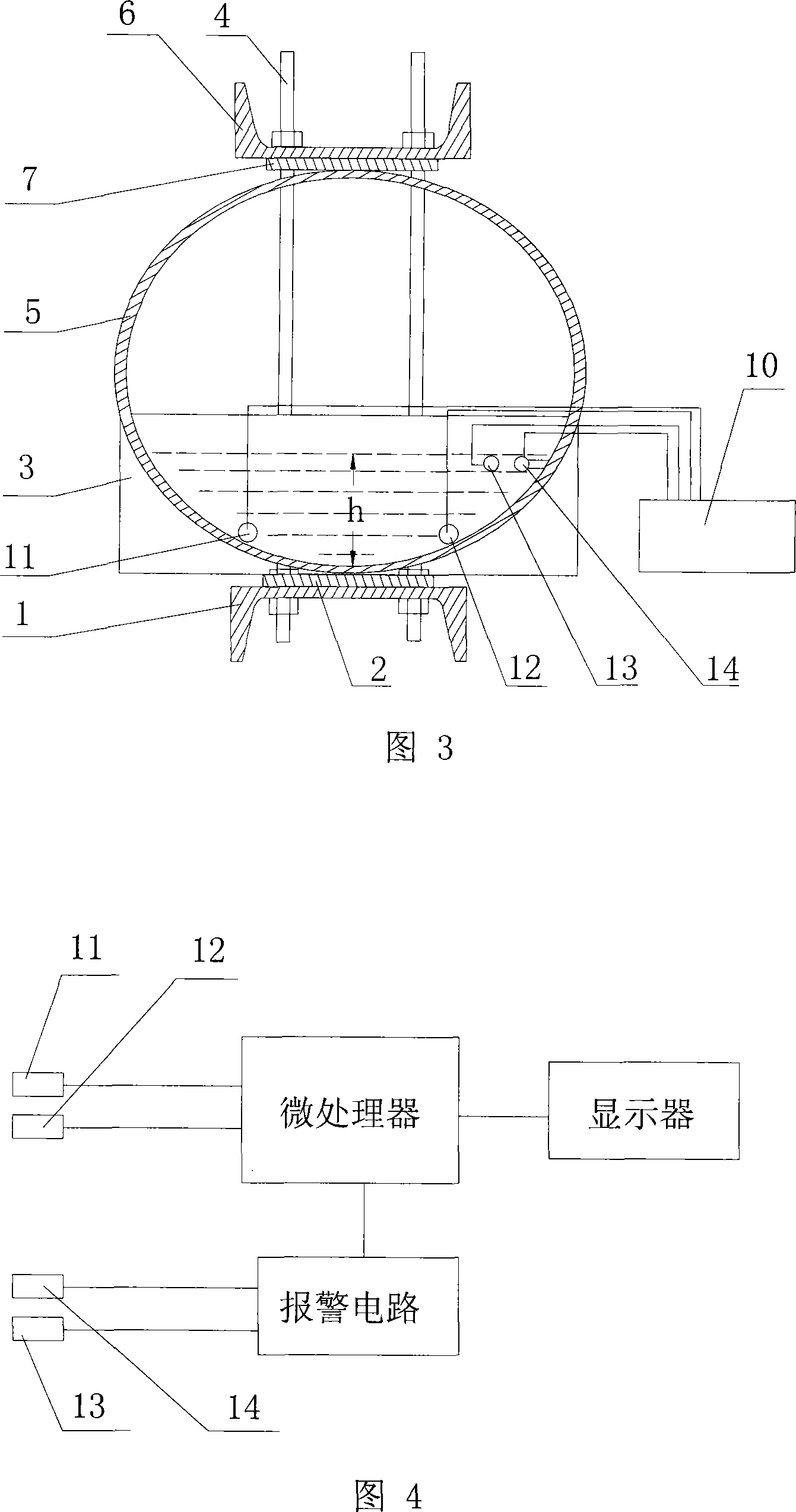

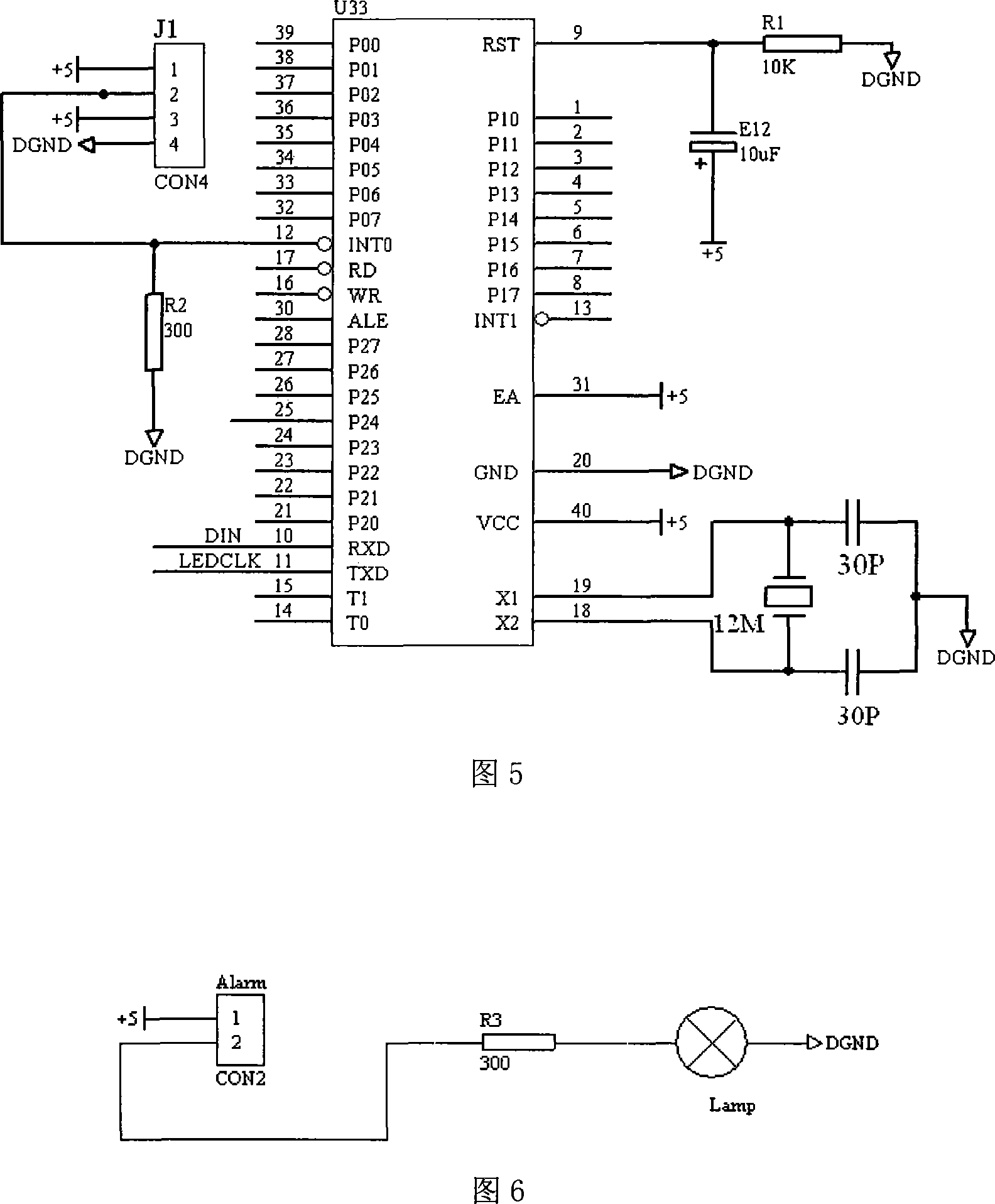

[0026] 1) Preparation of the long-term performance test device for glass steel pipes: as shown in Figure 1, Figure 2, and Figure 3, the long-term performance test device for glass steel pipes consists of a pull-down plate 1, a lower rubber pad 2, a left baffle plate 3, a left pull rod 4, and an upper pull-down plate. Plate 6, upper rubber pad 7, right tie rod 8, right baffle plate 9, and nuts;

[0027] 2) Place the lower rubber pad 2 on the pull-down plate 1, then place the glass steel pipe sample 5 to be tested on the lower rubber pad 2, place an upper rubber pad 7 on the upper end of the glass steel pipe sample 5, and place a rubber pad 7 on the upper rubber pad 7. Pull-up plate 6; the left end of pull-down plate 1 and pull-up plate 6 is fastened by left tie rod 4 and nut, the right end of pull-down plate 1 and pull-up plate 6 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com