Method for manufacturing inner stretching prestressed super-light structural variable girder module and components

A prestressed and tensioned technology, applied in the direction of girders, truss structures, joists, etc., can solve the problems of increasing the transportation volume and stacking materials, costing a lot of cement and steel, increasing the weight of buildings, etc. Cost, energy saving, good rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

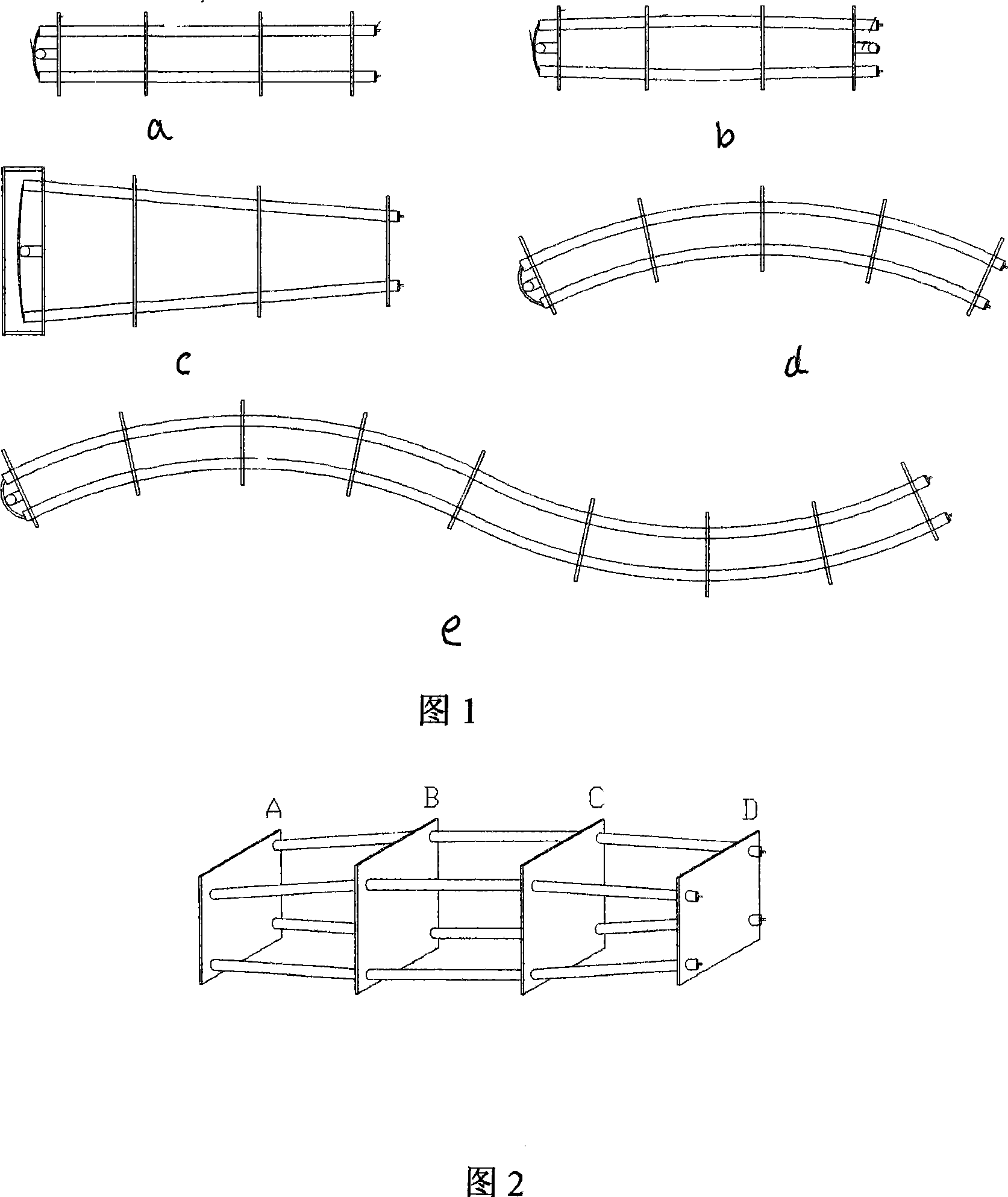

[0018] According to Figure 1 and Figure 2, wire ropes are inserted into the inner holes of the pipe fittings, the pipe fittings are connected with steel plates, and a guide piece is installed at one end of the pipe fittings. The steel wire ropes in the pipe fittings are pre-tensioned and pre-tensioned to the pre-designed tensile force. So far, after pre-tensioning to the required tension, the two ends of the rope are sealed with plugging heads, and the ultra-light structural unit is made. The ultra-light structural unit is connected with steel plates to make various beam module frames. The space of the frame is filled with structural blocks composed of lightweight fillers or pressurized plastic bottles, polyurethane and heat shrinkable film, and decorative surfaces are installed on the surface of the various beam module frames filled with fillers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com