Coiler for metallic rolled or drawn wires and/or rods

A technology of winding device and metal wire, which is applied in the directions of transportation and packaging, transportation of filamentous materials, thin material processing, etc., can solve the problems of downtime of winding equipment production line, production interruption, large wire flexibility, etc., and achieve fast hooking. material effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

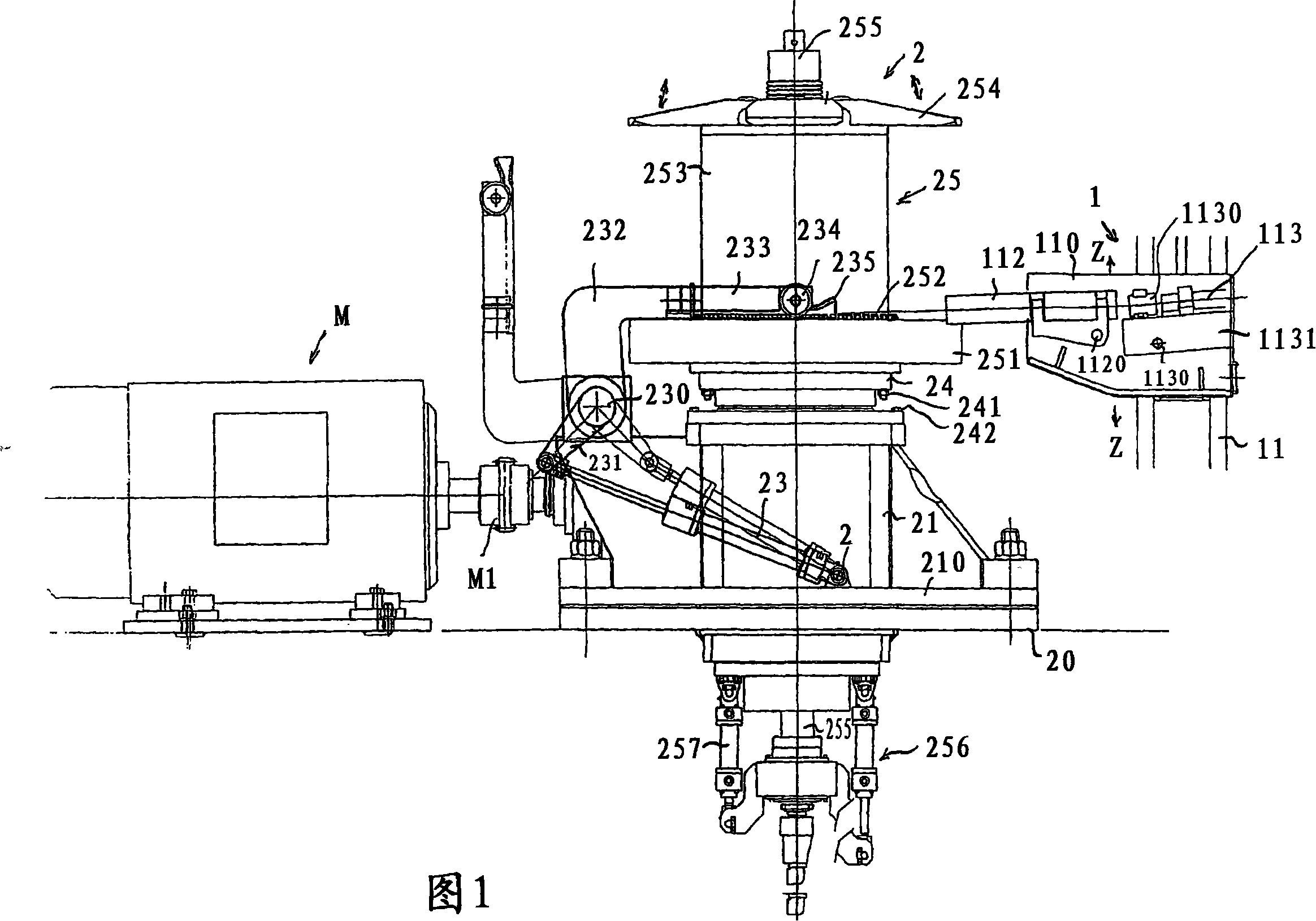

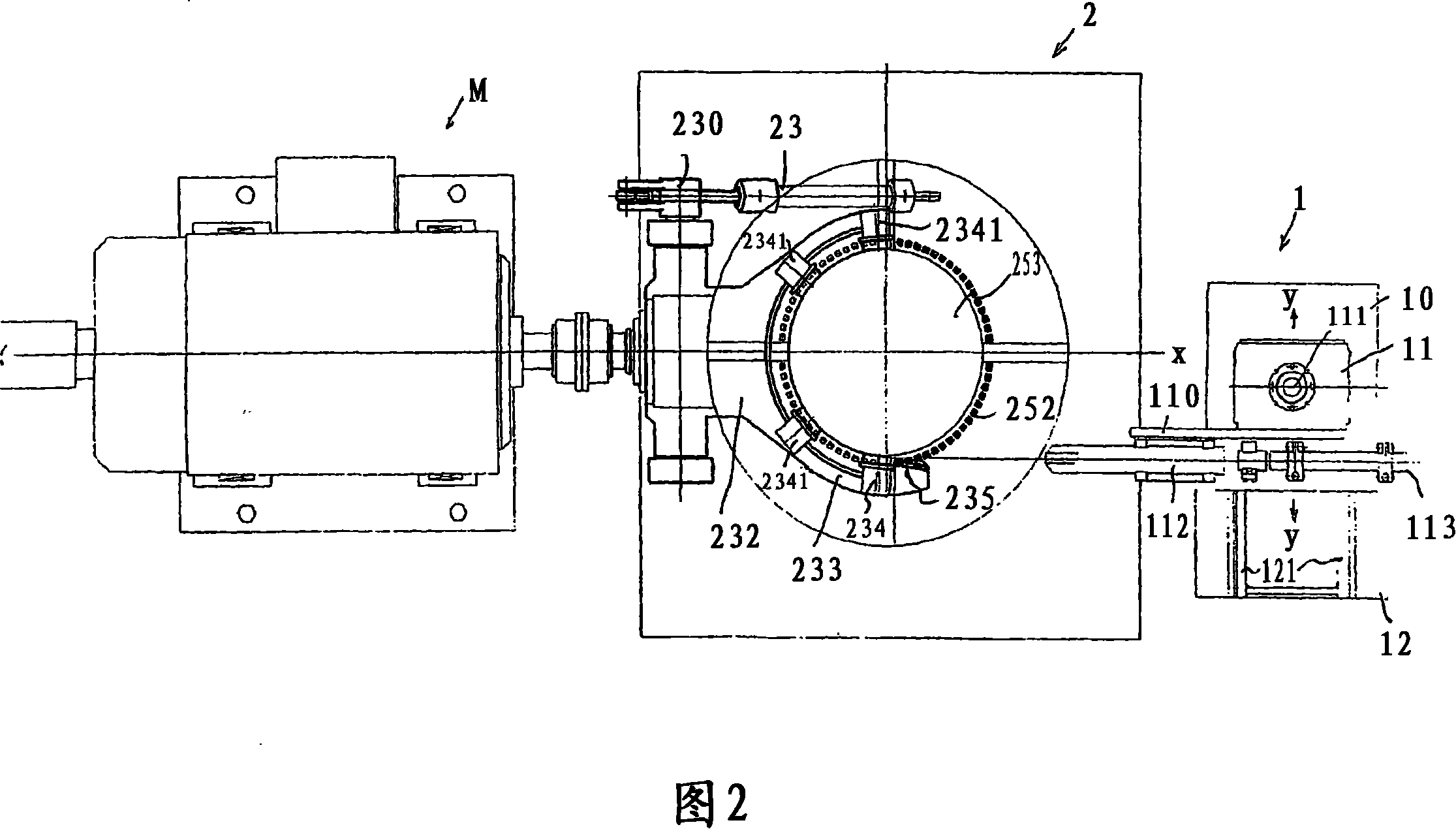

[0051] As can be seen from the figure, the take-up unit includes a winding device (2) associated with an electric device (M, M1), which is used to make the mandrel (25) of the winding device and A semi-circular hold-down device in the form of an open clamp (233) with hold-down rollers (234, 2341) on an arm (232) rotates, the arm being hinged ( 230) is hinged and driven by a return rod (231), wherein the piston (23) is hinged on the base (20) of the winding device (2).

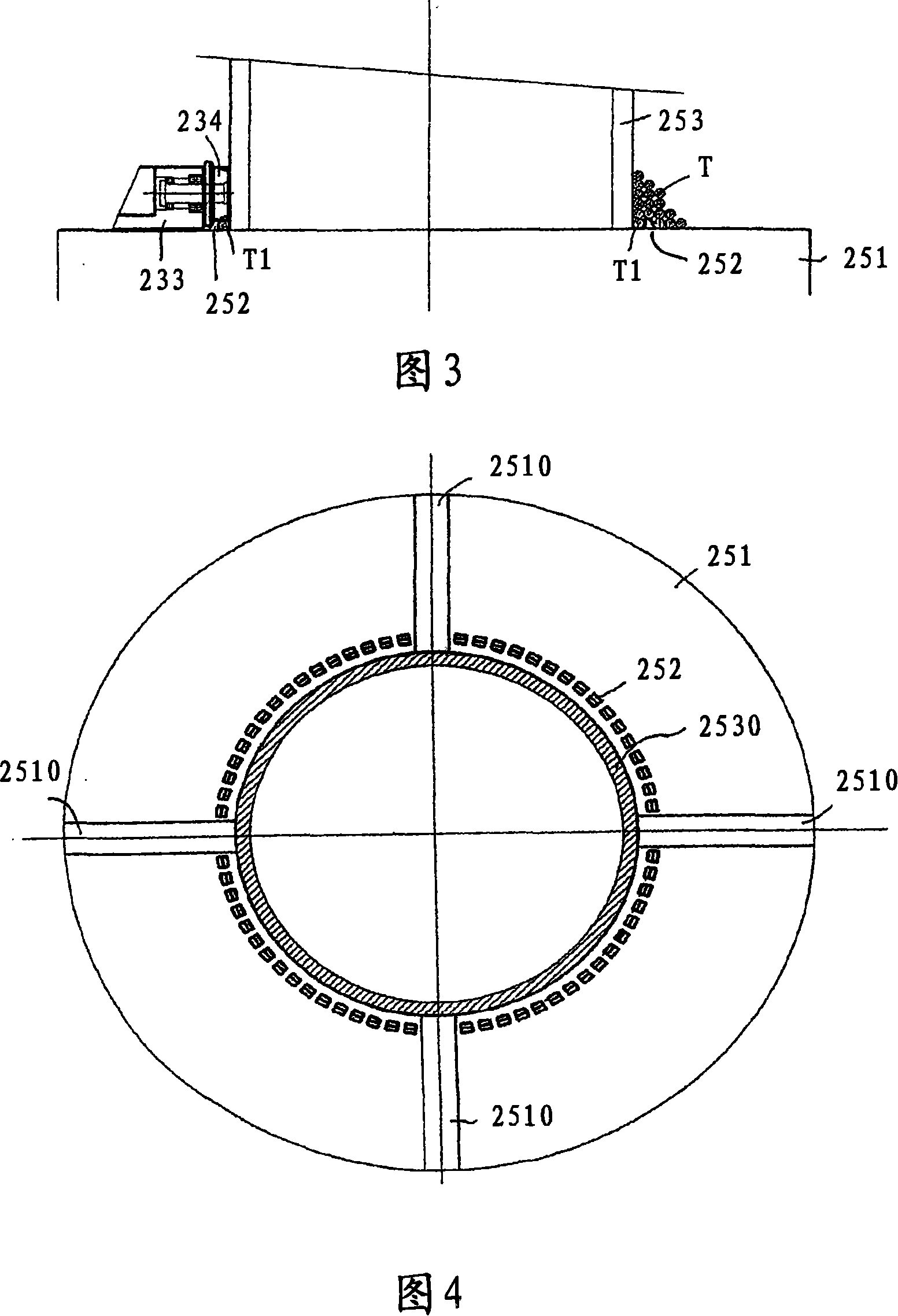

[0052] In this way, as indicated by thin lines, it consists of: the jaws (232, 233) with rollers that open towards the outside can be raised and lowered to press against the lower bottom of the winding mandrel (253). On the bottom flange (252), according to the invention, the lower bottom flange has toothed edges (252) for holding the material, so that the tongs also press on these teeth when they are lowered.

[0053] The entry of the wire is facilitated by a funnel-shaped entry on the entry side (235) of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com