Built-in type 4 axis sport controller

A motion controller, motion control technology, applied in non-electric variable control, position/direction control, control/regulation system and other directions, can solve problems such as inability to cut, system instability, system collapse, etc., to improve real-time performance and stability performance, cost reduction, and volume reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

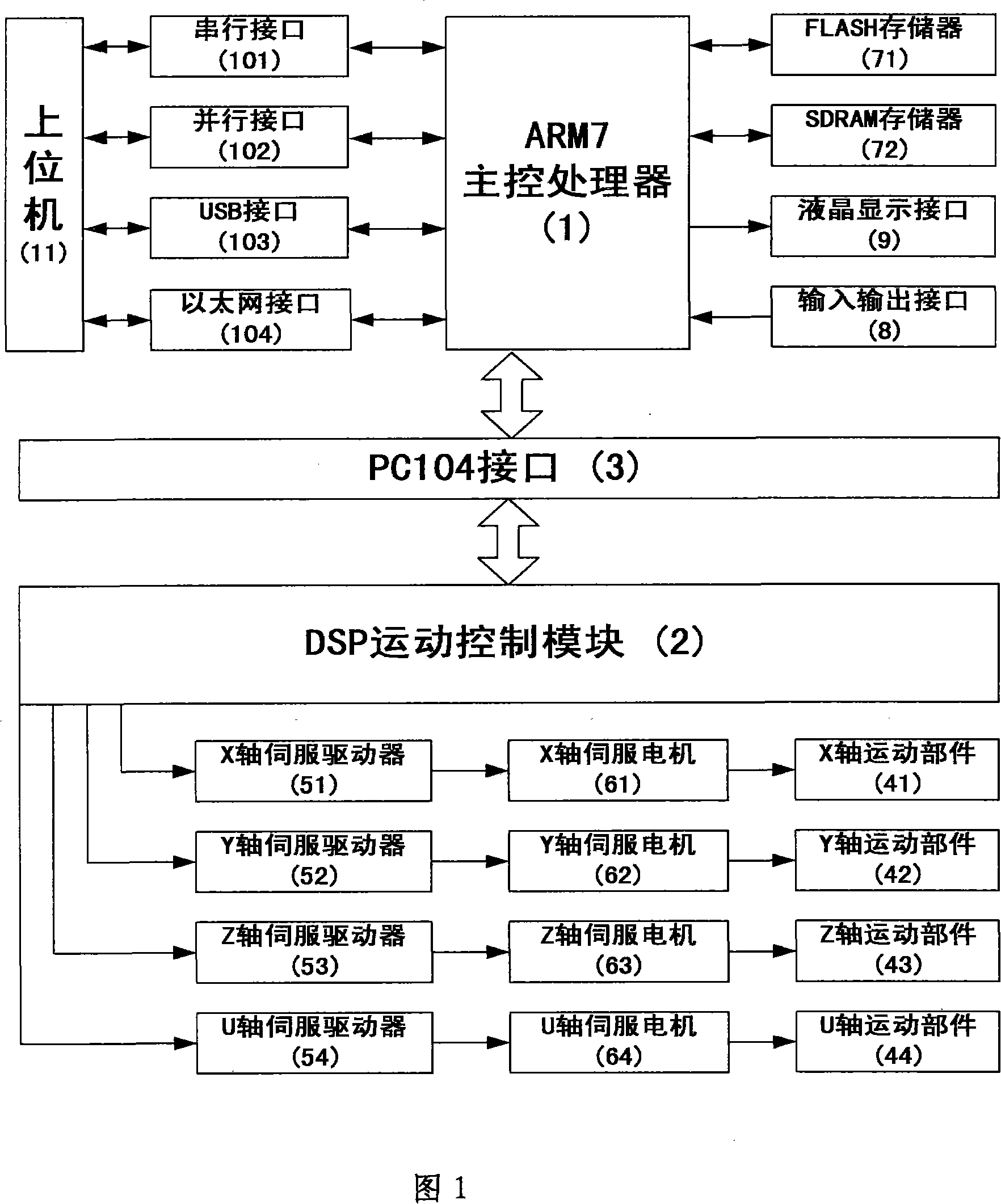

[0027] The principle block diagram of the present invention is as shown in Figure 1, comprises main controller 1 and motion control module 2, and the output end of main controller 1 is connected with motion control module 2 through output interface 3, and motion control module 2 moves with X axis respectively Part 41, Y-axis moving part 42, Z-axis moving part 43, and U-axis moving part 44 are connected.

[0028] Between the above-mentioned motion control module 2 and the X-axis moving part 41, the Y-axis moving part 42, the Z-axis moving part 43, and the U-axis moving part 44, an X-axis servo driver 51, a Y-axis servo driver 52, and a Z-axis servo driver are respectively arranged. Driver 53, U-axis servo driver 54, the output ends of motion control module 2 are respectively connected with X-axis servo driver 51, Y-axis servo driver 52, Z-axis servo driver 53, U-axis servo driver 54, X-axis servo driver 51, Y-axis servo driver Axis servo driver 52, Z-axis servo driver 53, and U...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com