Environmental protection energy-saving smokeless furnace

An environmentally friendly, energy-saving, smokeless furnace technology, applied in the direction of combustion air/fuel supply, combustion method, solid fuel combustion, etc., can solve the problems of non-compliance with environmental protection requirements, low combustion efficiency, and discharge of a large amount of harmful gases and smoke. To achieve the effect of solving energy crisis and environmental pollution, high economic and social benefits, and stable flame

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

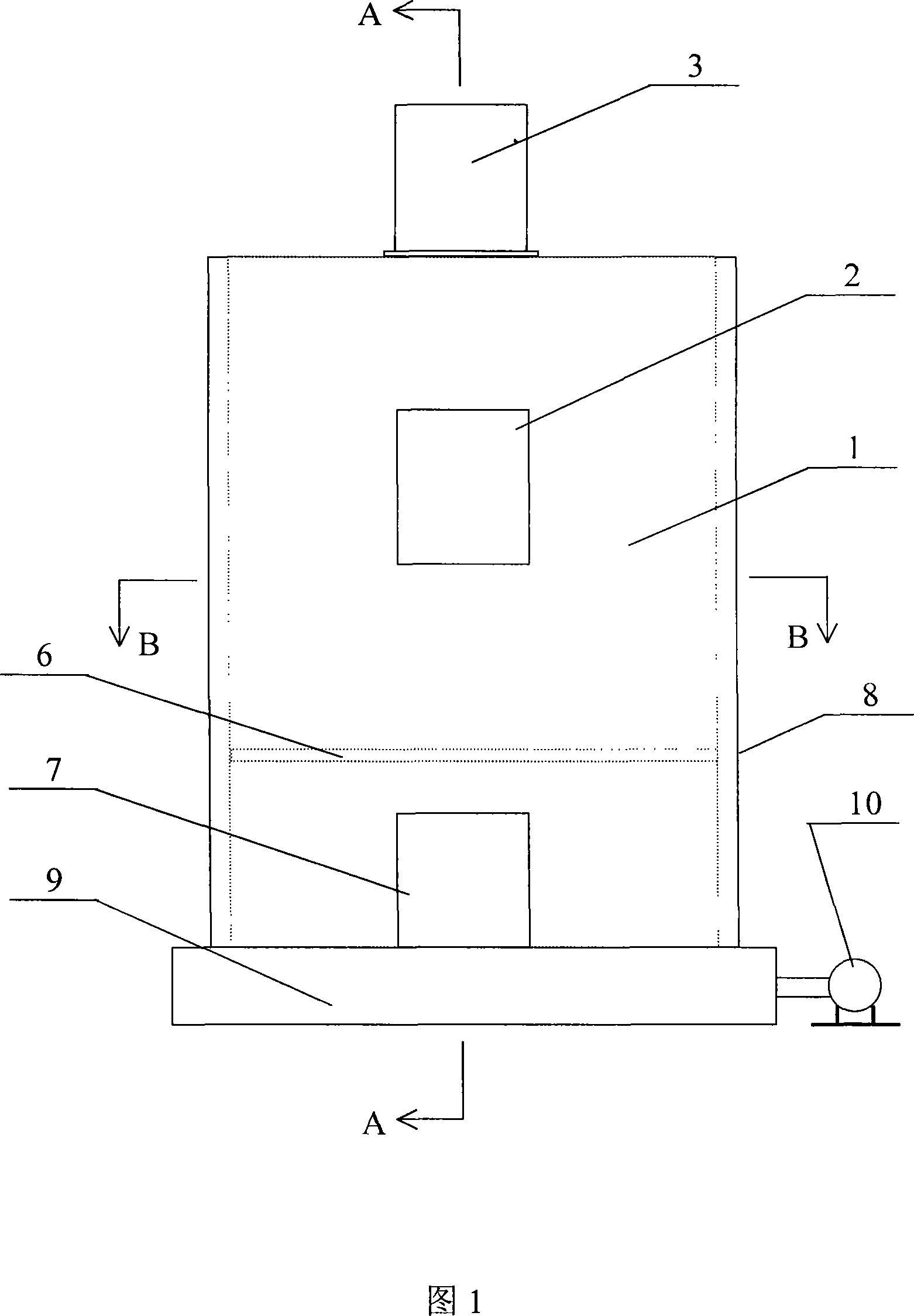

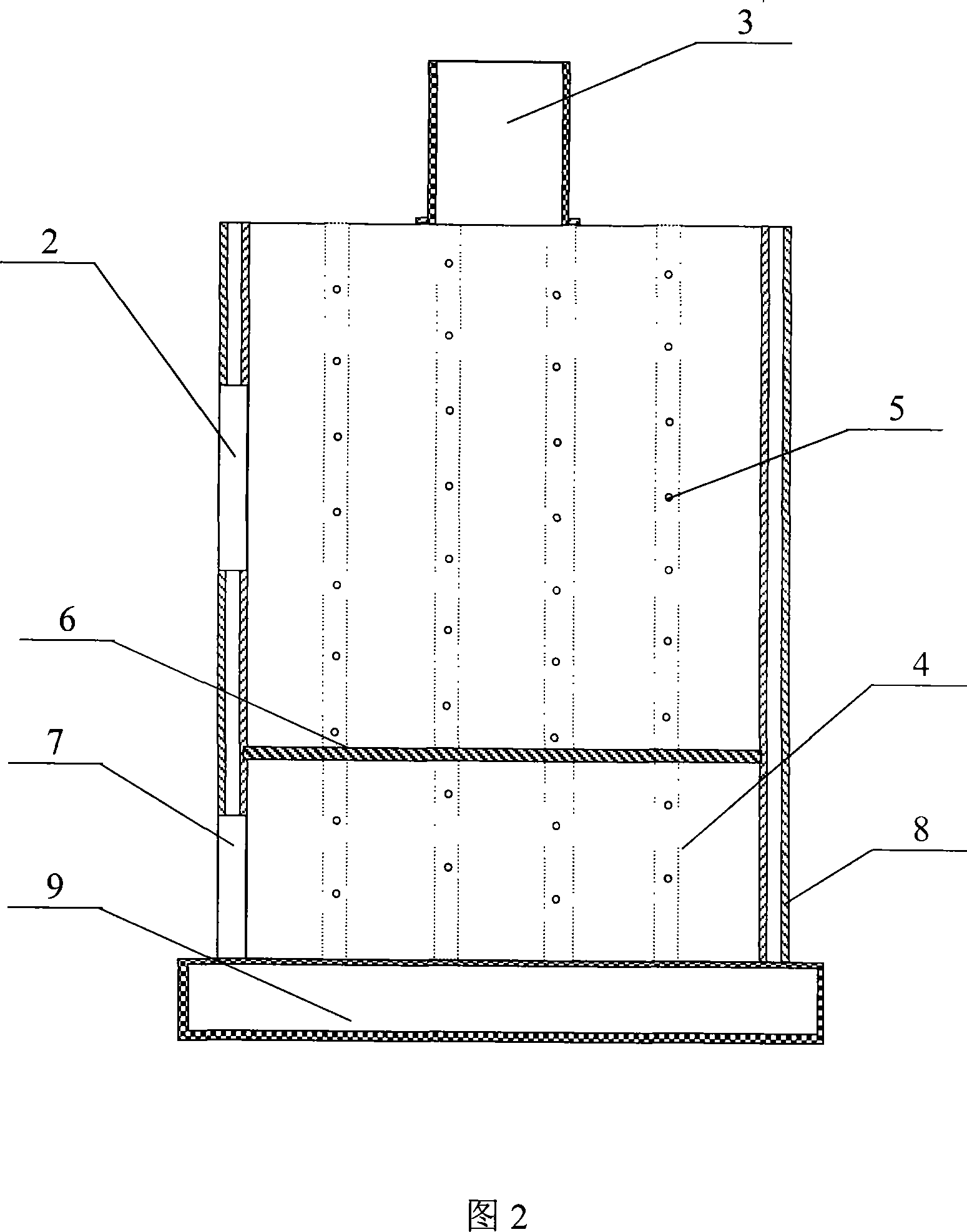

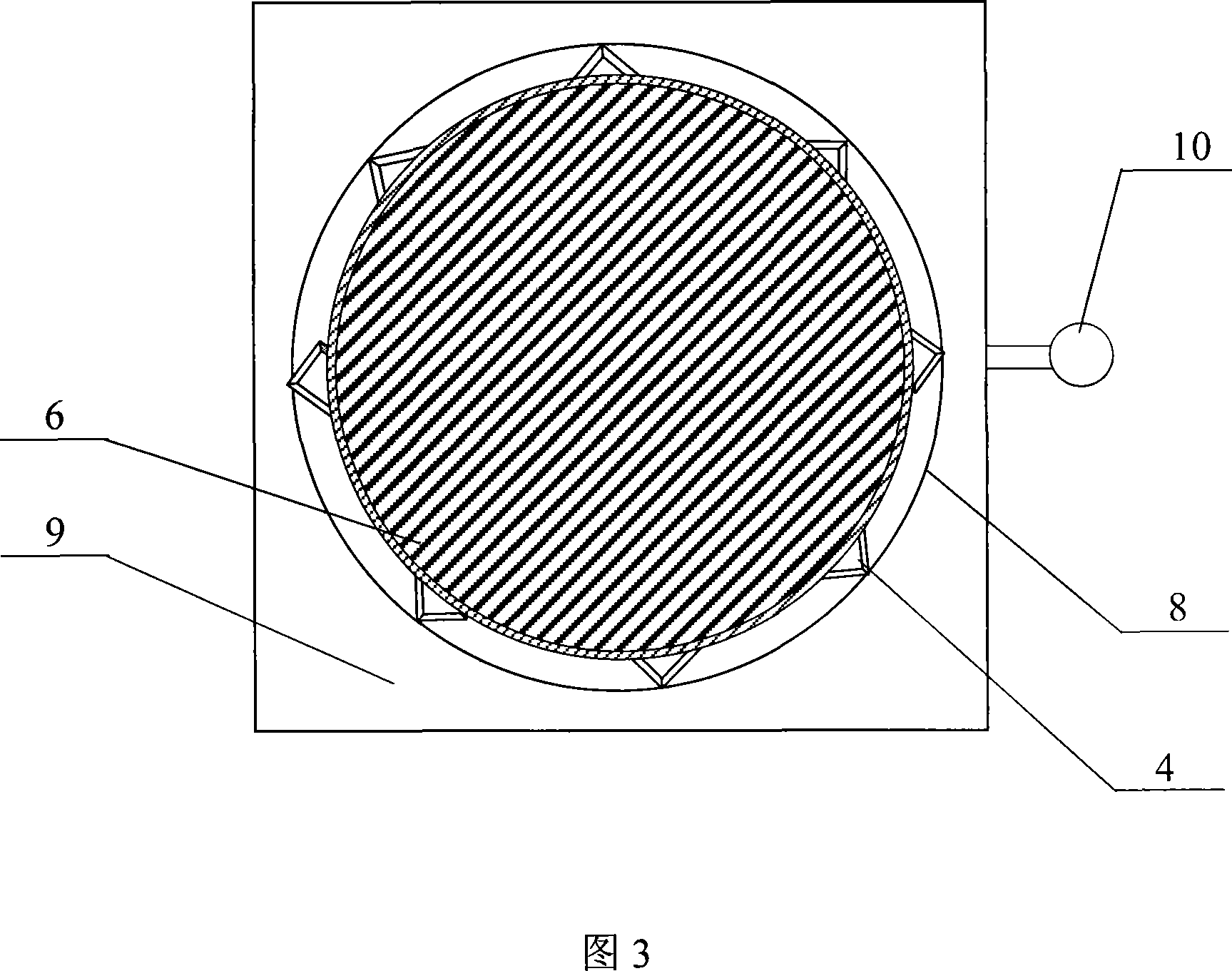

[0013] Referring to Fig. 1, Fig. 2, Fig. 3 and Fig. 4, the environment-friendly and energy-saving smokeless furnace includes: a furnace body 1, and a feed inlet 2, an ash discharge port 7 and a smoke outlet are arranged on the furnace wall of the furnace body 1 Mouth 3, furnace body 1 is connected with air box 9 that has blower 10, on the furnace wall of furnace body 1, a group of air ducts 4 are uniformly distributed along the circumference, and one end of air duct 4 communicates with air box 9; Each air duct 4 is provided with a group of air holes 5, and the air holes 5 communicate with the furnace.

[0014] The air duct 4 can be evenly distributed on the outside of the furnace wall along the perimeter of the furnace wall, and an outer cover 8 corresponding to the shape of the furnace body 1 is arranged outside the air duct 4; The inner side of the furnace wall or the air channels 4 are evenly distributed in the furnace wall along the circumference of the furnace wall. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com