Energy-saving heat-preserving internal partition plate module of building

A technology for building energy-saving and internal partition walls, which is applied to buildings, building components, building structures, etc., can solve the problems of complex structure, high cost, heavy weight, etc., and achieve the effect of good sound insulation, low cost and light weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

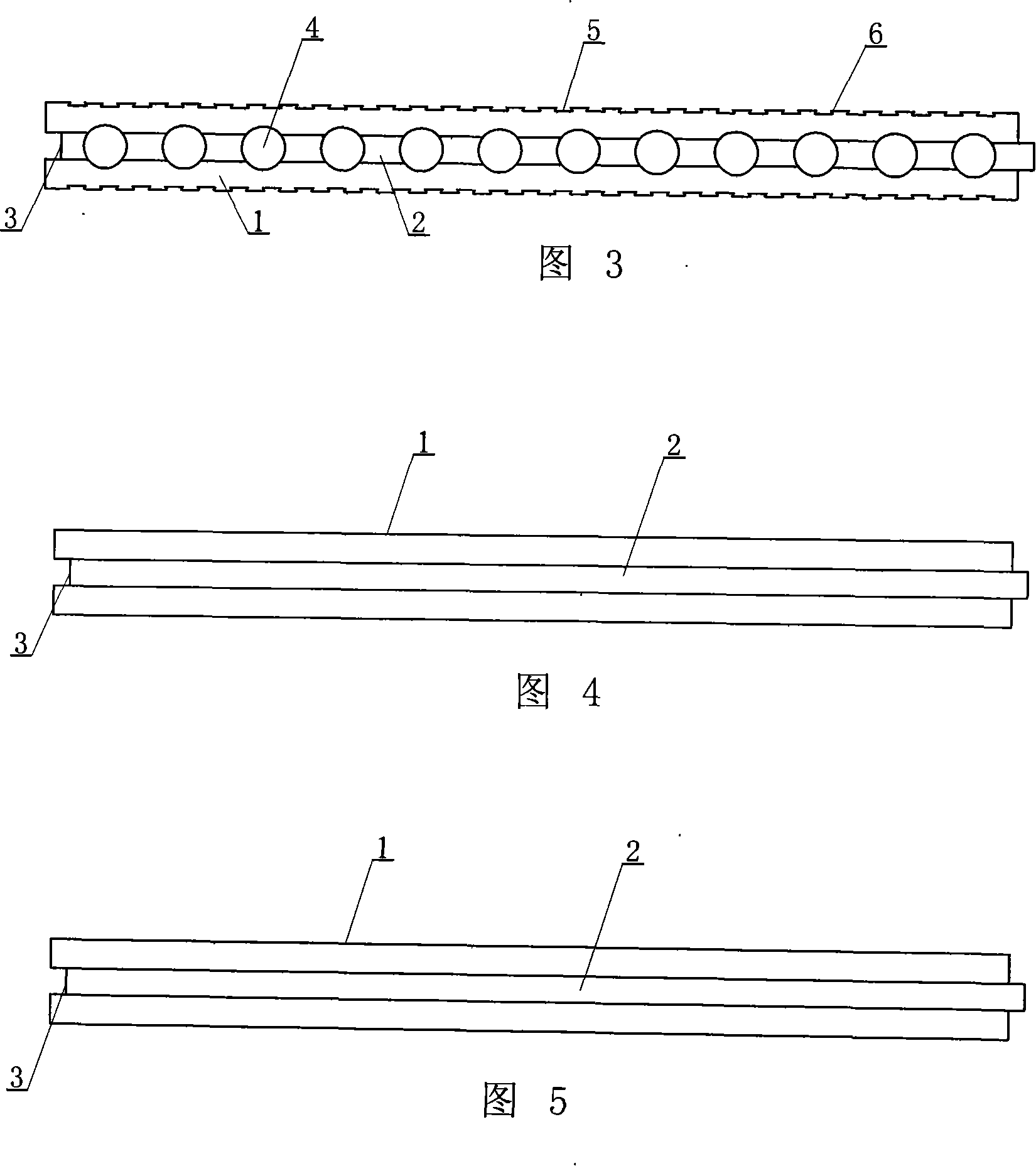

[0007] Specific Embodiment 1: This embodiment is described in conjunction with Fig. 1 to Fig. 5. This embodiment is composed of a polystyrene module 1; the two sides where the two sides of any apex angle α of the polystyrene module 1 are located The end face is provided with a tenon 2, and the polystyrene module 1 is provided with slots 3 on the two side faces of a vertex β on the same diagonal line as the arbitrary vertex α. , the socket joints 2 and slots 3 of two adjacent polystyrene modules 1 are matched, and a group of equidistant through holes 4 are arranged on the two parallel side ends of the polystyrene module 1, and the group of The through holes 4 run through the corresponding sockets 2 and slots 3. The number of through holes 4 provided on the polystyrene module 1 is 8 to 16, and the diameter Φ of the through holes 4 on the polystyrene module 1 is 30 to 30. 50mm, which can ensure a firmer connection between modules and improve the overall rigidity of the inner part...

specific Embodiment approach 2

[0008] Specific embodiment 2: This embodiment is described in conjunction with Fig. 1 to Fig. 3. The upper and lower surfaces of the polystyrene module 1 in this embodiment are respectively provided with a set of grooves, which can ensure that the module is firmly combined with the protective layer such as cement mortar on the surface. . Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0009] Specific embodiment three: This embodiment is described in conjunction with Fig. 1 to Fig. 3. A group of grooves 5 on the polystyrene module 1 of this embodiment are arranged equidistantly along the upper and lower surfaces of the polystyrene module 1, which can ensure that the module and the surface The covering cement mortar and other protective layers are firmly bonded and have good integrity. Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter φ | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com