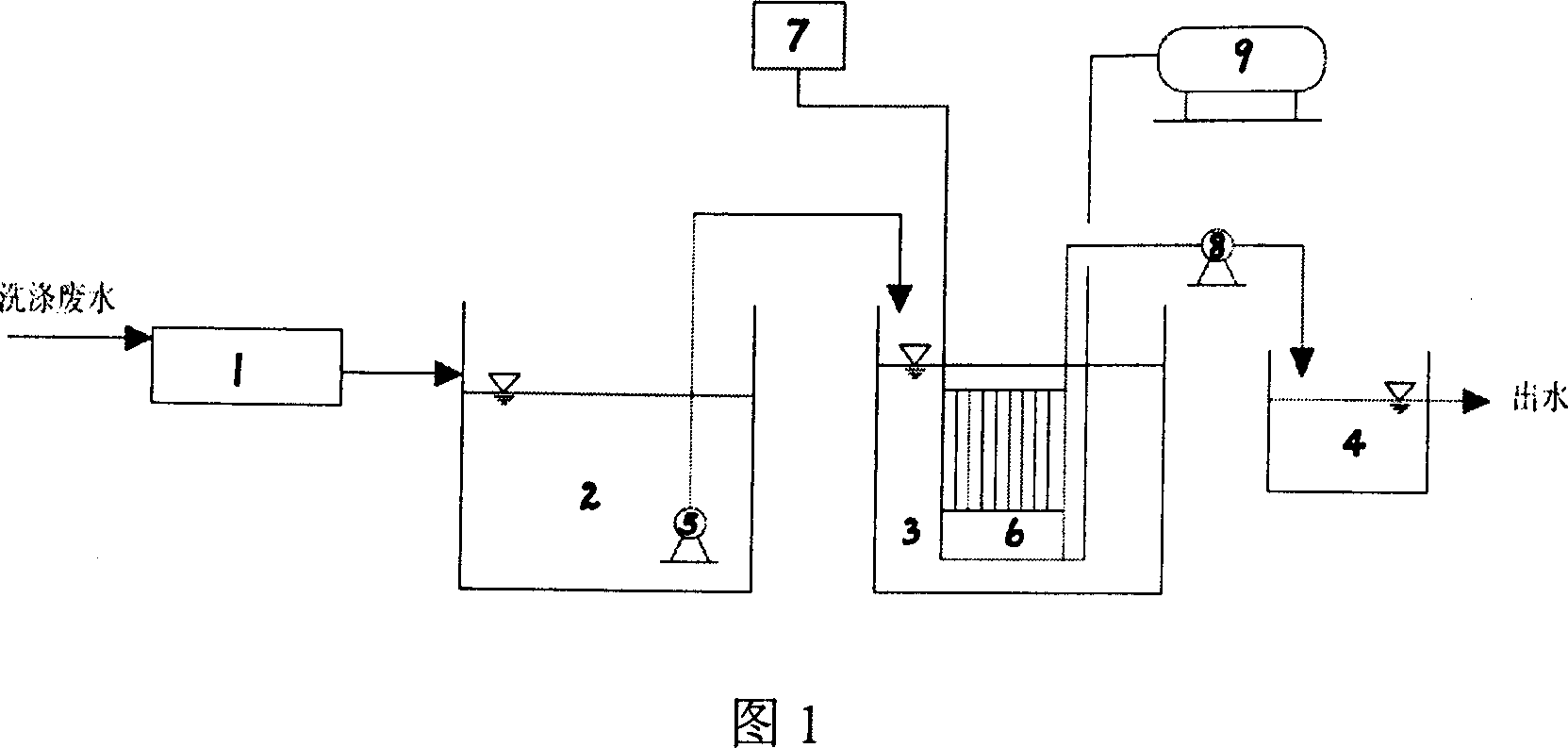

Treatment system for washing waste water

A waste water treatment system and waste water technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, aerobic process treatment, etc. Fast decay and other problems, to achieve the effect of low sludge production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Embodiment and result: the experimental treatment capacity of the present invention is by 42m 3 / day design, hydraulic retention time (HRT) = 4 ~ 6h. The processing conditions are shown in the table below. Except for the pollutants listed in Table 1, other pollution indicators have reached or exceeded the first-level standard for the maximum allowable discharge concentration of pollutants in the "Integrated Wastewater Discharge Standard" (GB8978-1996).

[0015] Table 1 Influent and effluent water quality in the test

[0016]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com