Instant heating type steam boiler

A steam boiler and instantaneous heating technology, applied in the direction of instantaneous steam boiler, steam boiler, steam generation, etc., can solve problems such as pipe blockage, and achieve the effect of reducing manufacturing cost, preventing precipitation or oxidation, and simple mold structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

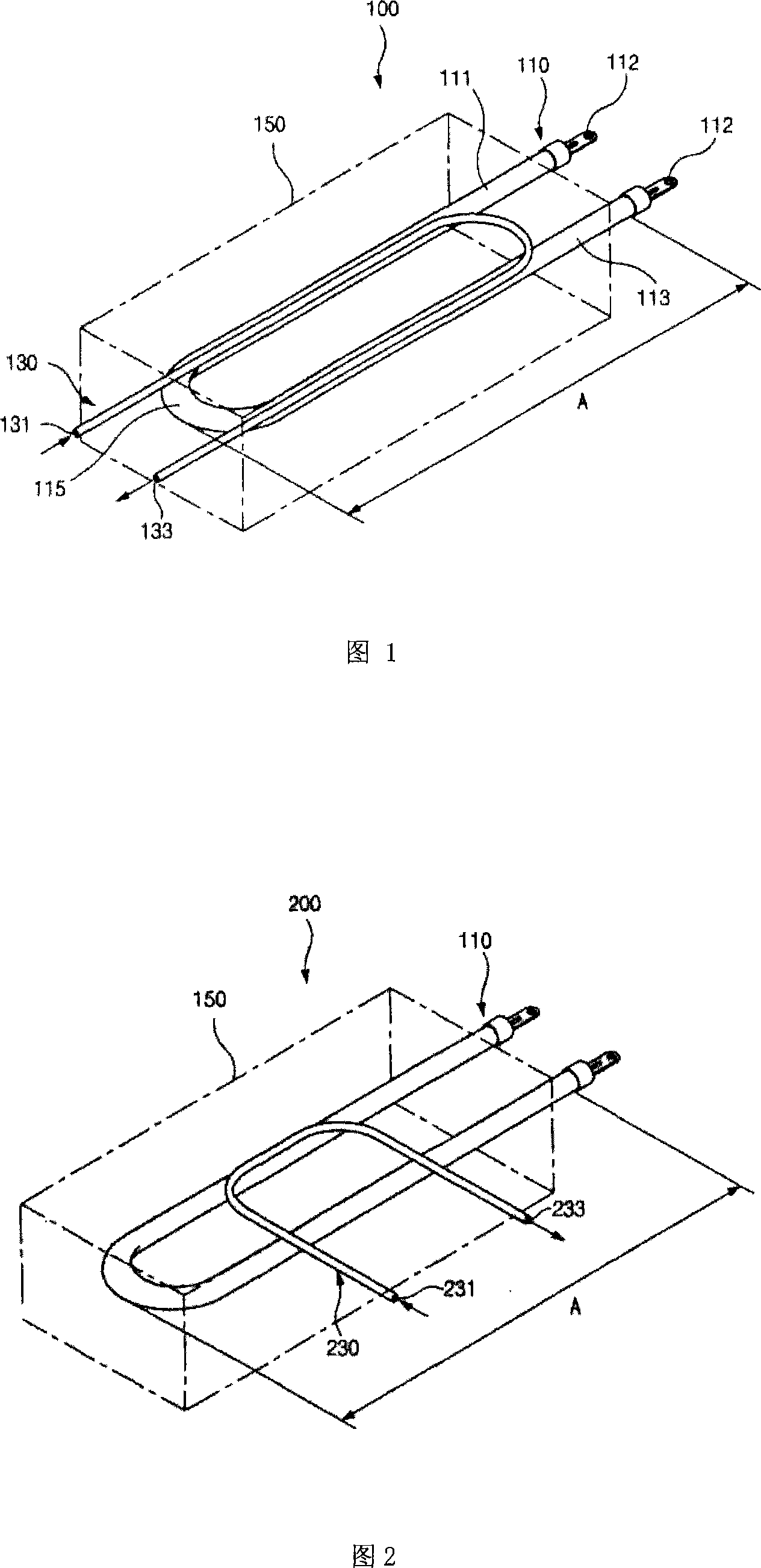

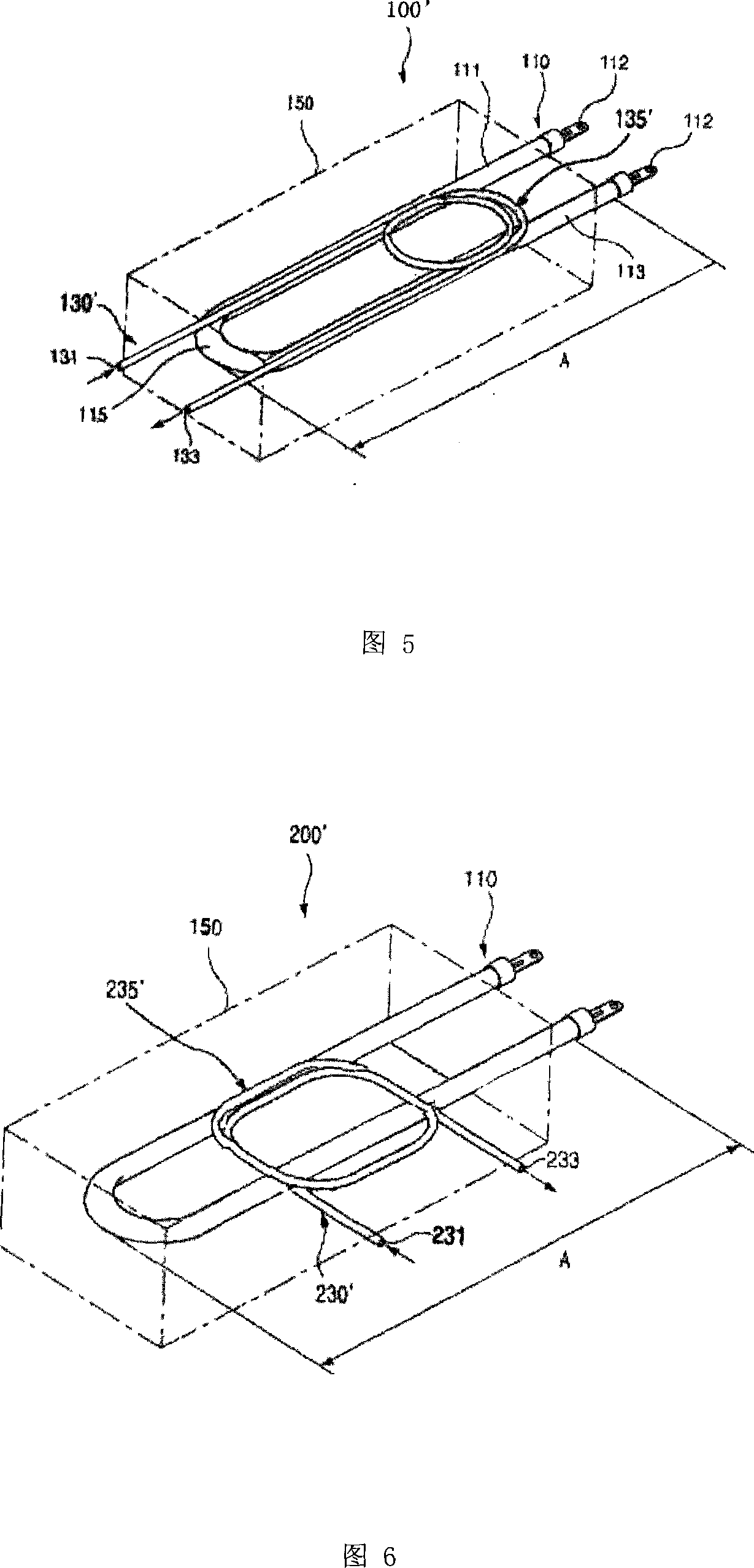

[0026] As shown in FIG. 1, the instant heating type steam boiler implemented according to this embodiment includes: a U-shaped electric heater 110, a water pipe 130 and a main body 150. Among them, a part of the electric heater 110 and a part of the water pipe 130 are buried in the main body 150. Because the water pipe 130 is arranged inside the main body 150, there is no need to manufacture the model required for the complicated pipe structure in the prior art.

[0027] The electric heater 110 adopts a U-shaped structure. The electric heater 110 includes a first straight portion 111, a second straight portion 113 parallel to the first straight portion, and an arc-shaped semicircular portion 115. One end of the first straight portion 111 and one end of the second straight portion 113 are connected by an arc-shaped semicircular portion 115, and the other end of the first straight portion 111 and the other end of the second straight portion 113 are both provided Connect terminal 112...

Embodiment 2

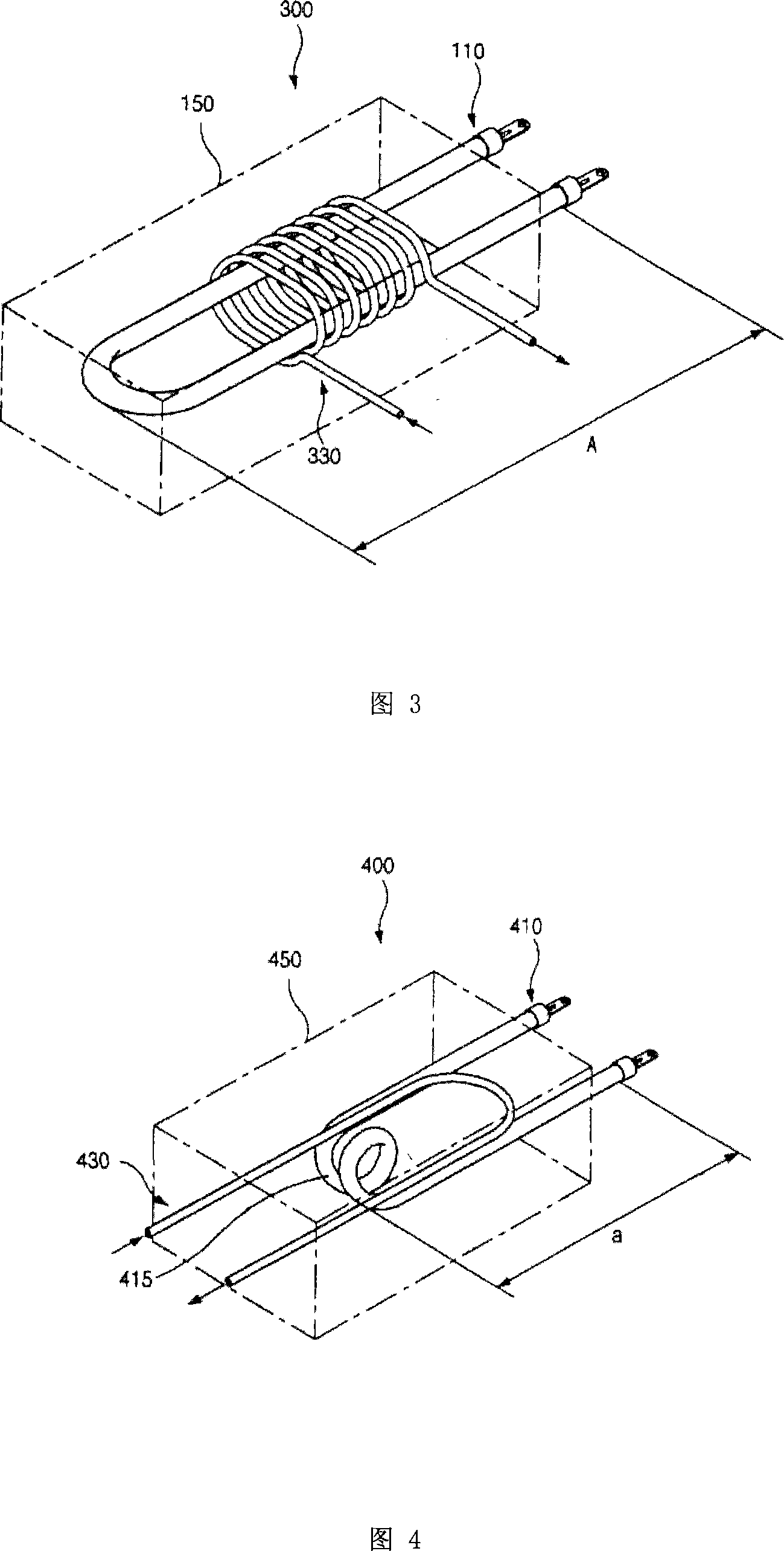

[0033] As shown in Figure 2, the instant heating steam boiler 200 according to this embodiment is similar in structure and function to the instant heating steam boiler 100 in the first embodiment, the difference is: the instant heating steam boiler 200 The water pipe 230 and the electric heater 110 are arranged perpendicular to each other. Therefore, the interval between the water inlet 231 and the steam discharge port 233 can be adjusted, and the arrangement range can be increased during product design.

Embodiment 3

[0035] As shown in Figure 3, the instantaneous heating steam boiler 300 according to this embodiment is similar in structure and function to the instantaneous heating steam boiler 200 in the second embodiment, the difference is: the instant heating steam boiler 300 The water pipe 330 adopts a coil winding arrangement, and the electric heater 110 is arranged inside the coil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com