Nickel-saving type cobalt-free martensite aging ultrahigh strength steel

An ultra-high-strength steel and martensite technology, which is applied in the field of nickel-saving cobalt-free maraging ultra-high-strength steel, can solve problems such as unachievable, and achieve the effects of low cost, resource saving and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

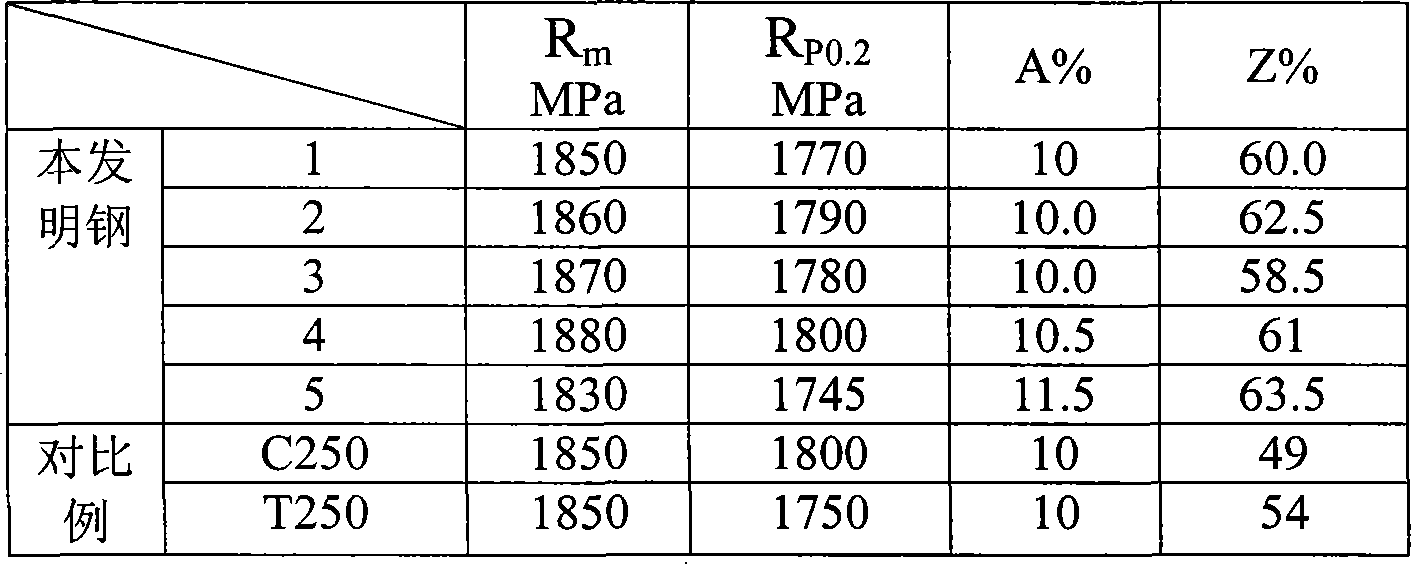

[0035] According to the chemical composition range of the cobalt-free and nickel-free maraging steel of the present invention, 3 furnaces of the steel of the present invention were smelted on a 20 kg vacuum induction furnace, and its specific chemical composition is shown in Table 1.

[0036] 3 After furnace steel is smelted and cast into ingots, it is subjected to homogenization heat treatment, forged into mechanical performance samples, and then subjected to solid solution and aging treatment. Its specific process parameters are as follows:

[0037] The homogenization heat treatment temperature of the steel ingot is 1200°C for 6 hours.

[0038] Thermal processing Heating temperature 1150-1180 ℃, heating time 1 hour.

[0039] Solid solution temperature 830~900℃, heating time 1 hour, air cooling

[0040] The aging temperature is 500°C and the time is 5 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com