Method for purifying sea animal cultivation sewage

A technology for marine animals and aquaculture sewage, applied in chemical instruments and methods, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as aquaculture pollution, and achieve good results, simple procedures, and reduced morbidity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

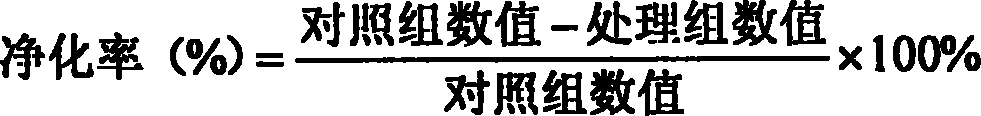

[0029] Purification effect of luxuriant membrane sponge on flounder aquaculture wastewater:

[0030] According to the inventive method, the luxuriant membrane sponge is collected in the sea area, washed with clean sea water, put into an incubator (6-10° C.) refrigerated with ice cubes, and transported back to the laboratory. Rinse the sponge three times with sand-filtered seawater at 18°C, and bind 5 sponge blocks weighing about 15g each with 0.2g polyethylene ropes to 5 polyethylene plate attachment bases washed with sand-filtered seawater and each weighing 15g. Suspended in a glass rearing tank filled with 50L flounder breeding sewage, slightly inflated, dissolved oxygen 6.2mg / l. The water temperature is 18±2°C. Change the water once every morning and evening, and suck out 25L of water from the bottom of the breeding tank each time with a siphon, and then add 25L of fish farming sewage with the siphon. After 2 days, all 5 sponges were attached to the attachment base. Afte...

Embodiment 2

[0035] The purification effect of the luxuriant membrane sponge on the aquaculture sewage in the sea cucumber pond:

[0036] A sea cucumber breeding pond was selected at the seaside of Guojiagou Village, Lvshun, Dalian City. The dams on the east and west sides are 100M long, and the dams on the north and south sides are 80M long. The height of the dams ranges from 0.5M to 3.5M from north to south. When the tide is low, the dam is exposed to the water surface, so that the sea cucumber pool is isolated from the outside water body; when the tide is high, the dam is submerged in the sea water, and the water of the sea cucumber pool is integrated with the outside sea water.

[0037] Cables are installed at a height of 3m on both sides of the east and west dykes, and a float is tied every 6 meters on the cables. Two adjacent buoys (points A and B) in the middle area of the cable, where the water depth and bottom quality are basically the same, are selected as the experimental poin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com