Steel cable traction wavy baffle edge belt conveyer

A wire rope and conveyor technology, applied in the field of machinery, can solve problems affecting equipment maintenance, slumping material scattering, shutdown and production shutdown, etc., to achieve the effects of reducing the phenomenon of slumping material scattering, large lifting angle, and increased cargo capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

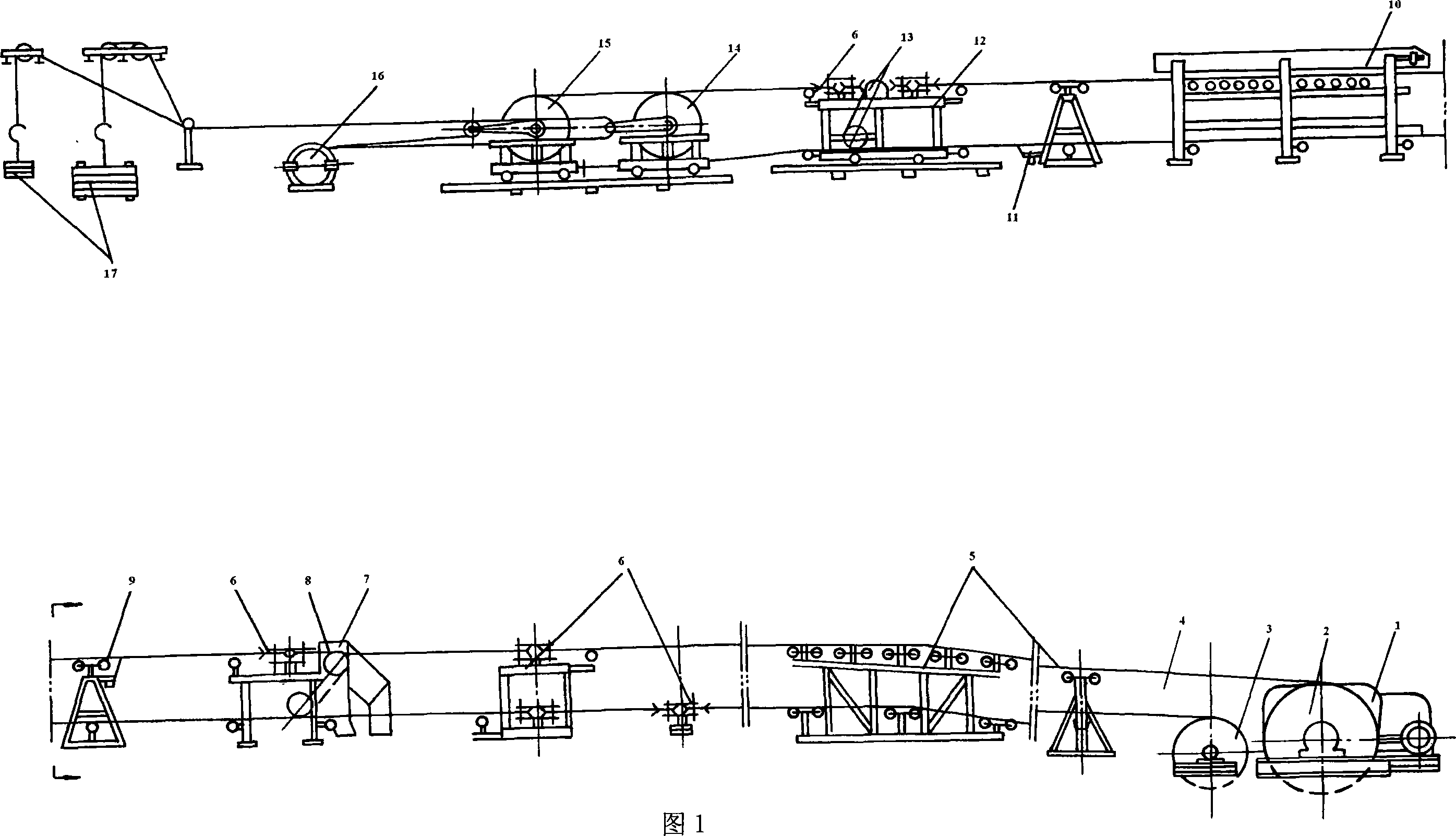

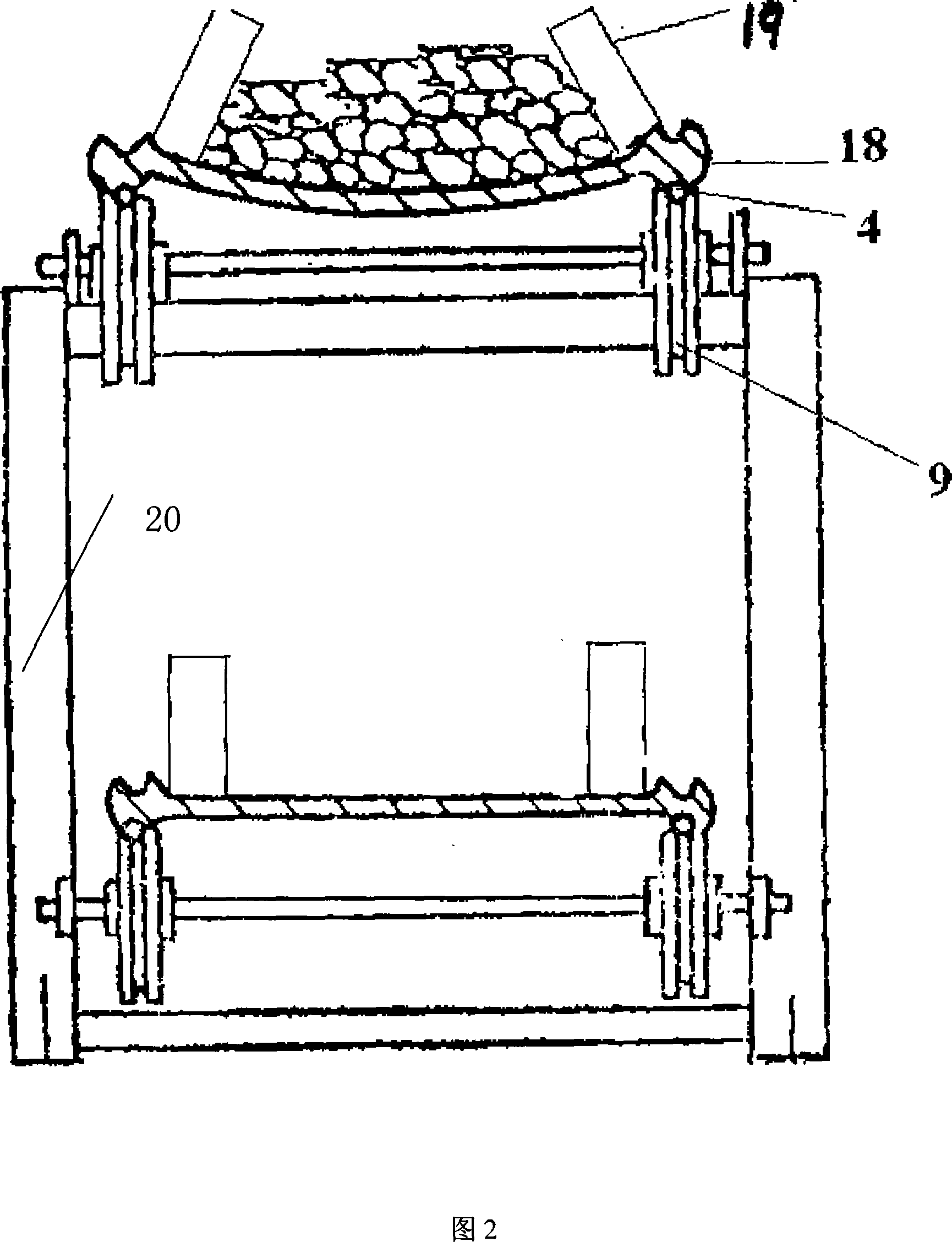

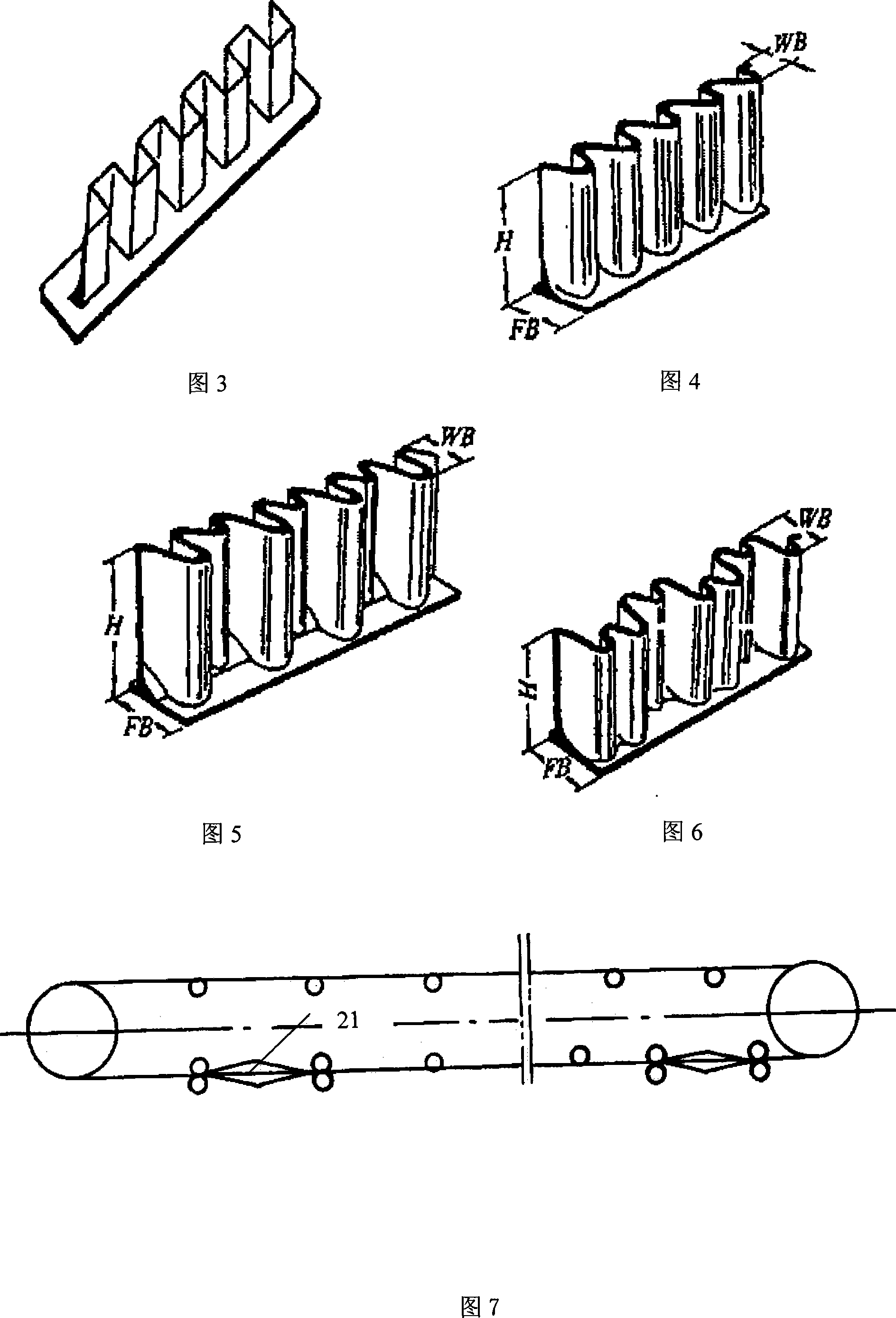

[0016] The present invention is shown in Fig. 1, Fig. 2, Fig. 7, and the present invention comprises 1, driving device; 2, driving wheel; 3, guide sheave; 4, traction wire rope; ;7. Unloading device; 8. Head reversing drum; 9. Intermediate sheave set; 10. Loading device; 11. Conveyor belt tensioner; 12. Car; 13. Tail reversing drum; 14. Wire rope Tensioning car; 15. Tensioning rope wheel; 16. Tensioning winch; 17. Tensioning weight; 18. Conveyor belt; 19. Conveyor belt rib; 20. Bracket; Conveyor belt ribs 19 are installed at both ends of the conveyor belt 18 . The conveyor belt turning mechanism 21 is arranged at both ends of the conveyor belt 18 .

[0017] Conveyor belt rib 19 shape of the present invention can have following several forms, and rectangle is shown in Fig. 3, and S shape is shown in Fig. 4, and W shape is shown in Fig. 5, and WM shape is shown in Fig. 6.

[0018] In the application of the conveyor belt turning mechanism 21 of the present invention, the follow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com