Selecting technology during preparing grass material

A process and raw material technology, applied in the direction of raw material separation, sieving, solid separation, etc., can solve the problems of pulp macular and pulp prone to macular, and achieve the effect of less dust spots and improved paper quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

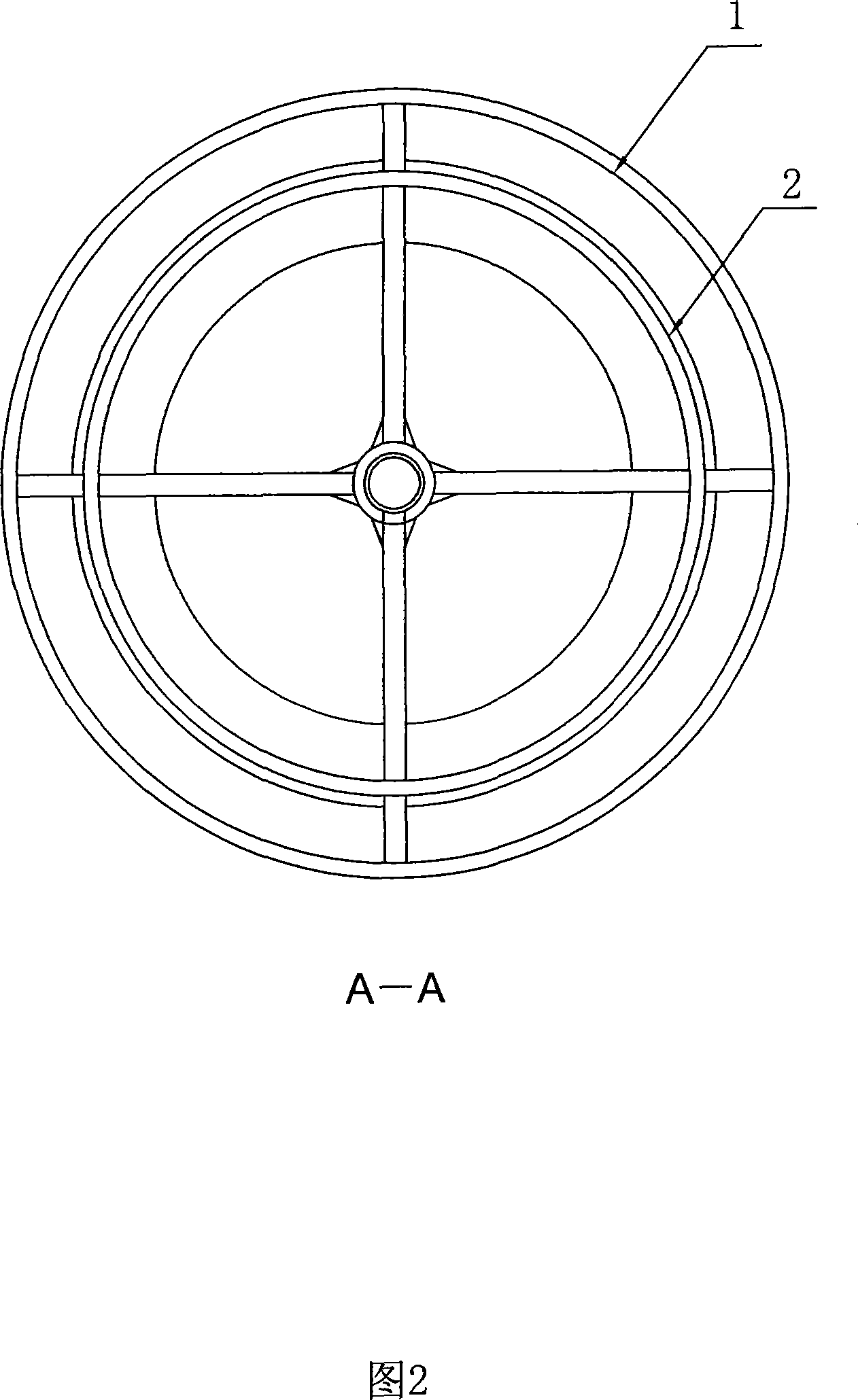

[0038]Referring to Fig. 1, get 5 tons of straws with a moisture content of 10%-22% and a length of 300-350mm, slice them, cut them into grass slices with a length of 20-80mm and knead their knots, slice and The grass flakes obtained after kneading are transported into the cyclone separator for dust removal, and the dust, grass clippings, and ears with low density in the grass flakes are extracted from the separator, and the grass flakes are not drawn out due to their large weight, and then conveyed Screening in the cylinder sieve, the impurity content in the grass slices entering the cylinder sieve is 18%, the cylinder sieve is placed inclined relative to the horizontal ground, and the inclination between the horizontal plane is 6°, the sieve of the inner screen basket on the cylinder sieve The hole is a square screen hole, the side length is 30×30mm, and the rotation speed is 10 rpm. The screen hole of the outer screen basket on the cylindrical screen is a round hole, and the ...

Embodiment 2

[0040] Referring to Figure 1, take 5 tons of wheat straw with a moisture content of less than 10%, slice it and knead it, cut it into small sections with a length of 20--50 mm, and require that the wheat straw can be kneaded, and the wheat straw slices obtained after slicing are transported into the Dust removal is carried out in the cyclone separator. The dust, grass clippings and ears with low density in the grass slices are extracted from the separator. The wheat straw slices will not be drawn out due to their large weight, and then they are transported to the cylinder screen for screening. The impurity content in the wheat straw flakes entering the cylinder sieve is 20%. The cylinder sieve is placed obliquely relative to the horizontal ground, with an inclination of 8° between the horizontal plane. The sieve holes of the inner sieve basket on the cylinder sieve of the cylinder sieve are square The sieve hole is 30×30mm, and the sieve hole of the outer screen basket of the c...

Embodiment 3

[0042] Take cotton stalks with a moisture content below 18% and slice them into small sections with a length of 20 mm. The cotton stalks obtained after slicing are transported into a cyclone separator for dust removal. The dust, grass clippings, The ear is drawn out from the separator, the cotton stalk will not be drawn out because of its large weight, and then it is transported to the cylinder screen for screening. The impurity content in the cotton stalk entering the cylinder screen is 22%, and the cylinder screen is relatively It is placed on a horizontal ground with an inclination of 10° to the horizontal plane. The dust-removed grass slices first enter the inner screen basket 2 of the cylindrical screen. The speed of the inner screen basket is 12 rpm, and the speed of the outer screen basket is maintained at 20. rpm, when the cylinder sieve rotates around the shaft, the grass flakes pass through the inner screen basket of the cylinder sieve and enter the outer screen baske...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com