Arrangement for sucking dust

A technology of suction device and cleaning device, which is applied in the direction of safety device, dust prevention, fire prevention, etc., can solve the problem of not being able to effectively prevent dust, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

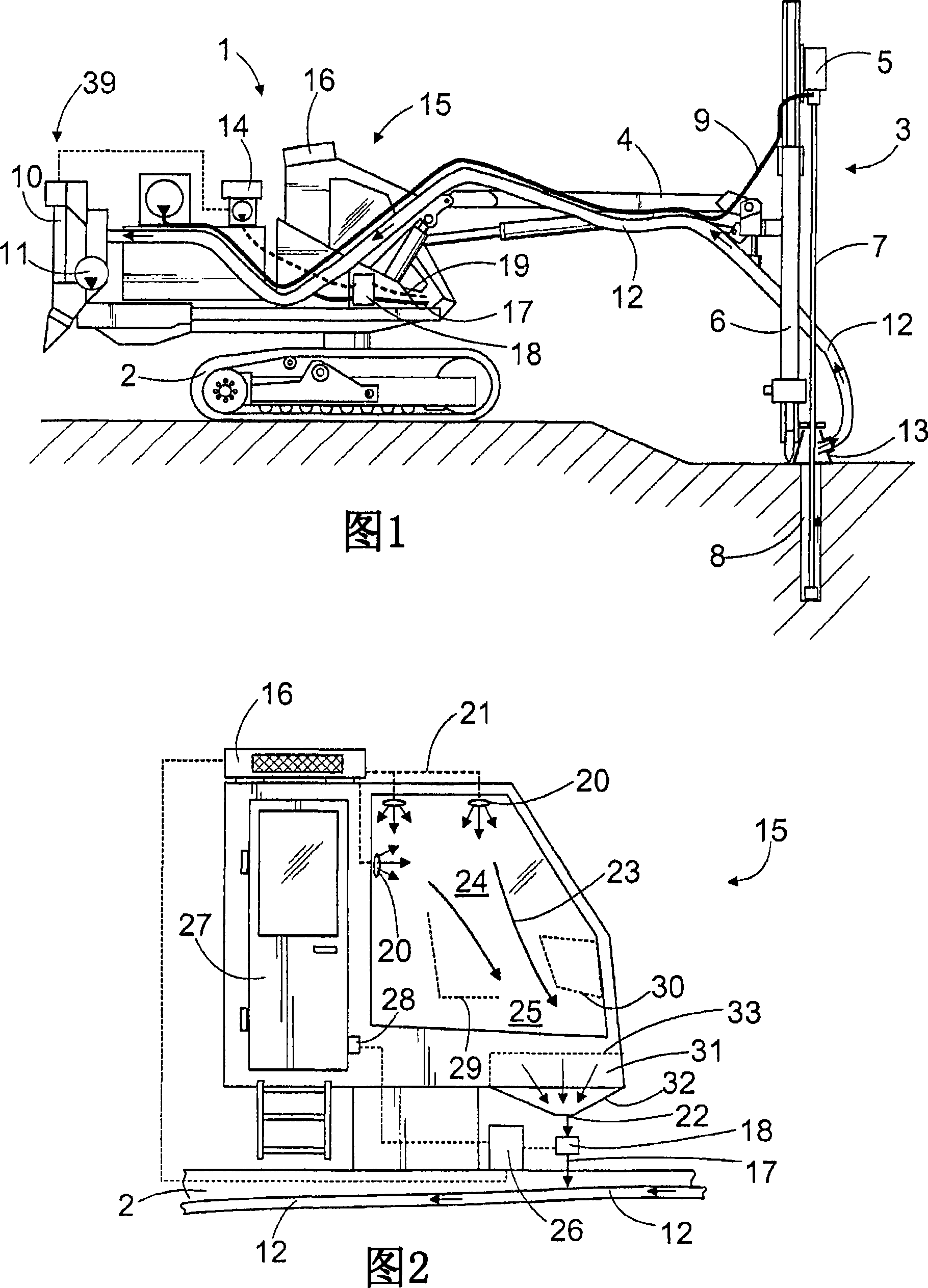

[0028] FIG. 1 shows a rock drilling rig 1 , which may comprise a movable carrier 2 with a boom 4 equipped with one or more rock drilling rigs 3 . The rock drilling arrangement 3 may comprise a rock drilling machine 5 movable on a feed rod 6 . The rock drill 5 has a percussion device which can be used to transmit a percussion impulse to the tool 7 which causes the tool to break the rock and form a borehole 8 . Cuttings (ie dust) and other rock material produced in the drilling are washed out of the borehole 8 during drilling. A flushing medium, such as compressed air, may be supplied through the flushing medium tank 9 and into the borehole 8 through the tool 7 to push cuttings towards the exit of the borehole 8 . The rock drilling rig 1 may comprise a dust collection system that sucks cuttings from the outlet of the borehole 8 and brings them to a filter 10 that separates solid material from air. The dust collection system may comprise a suction device 11 which may be located...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com