Tyre module and tyre comprising a module of this type

A tire module, pneumatic tire technology, applied in tire measurement, tire parts, electrical components and other directions, can solve problems such as complex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

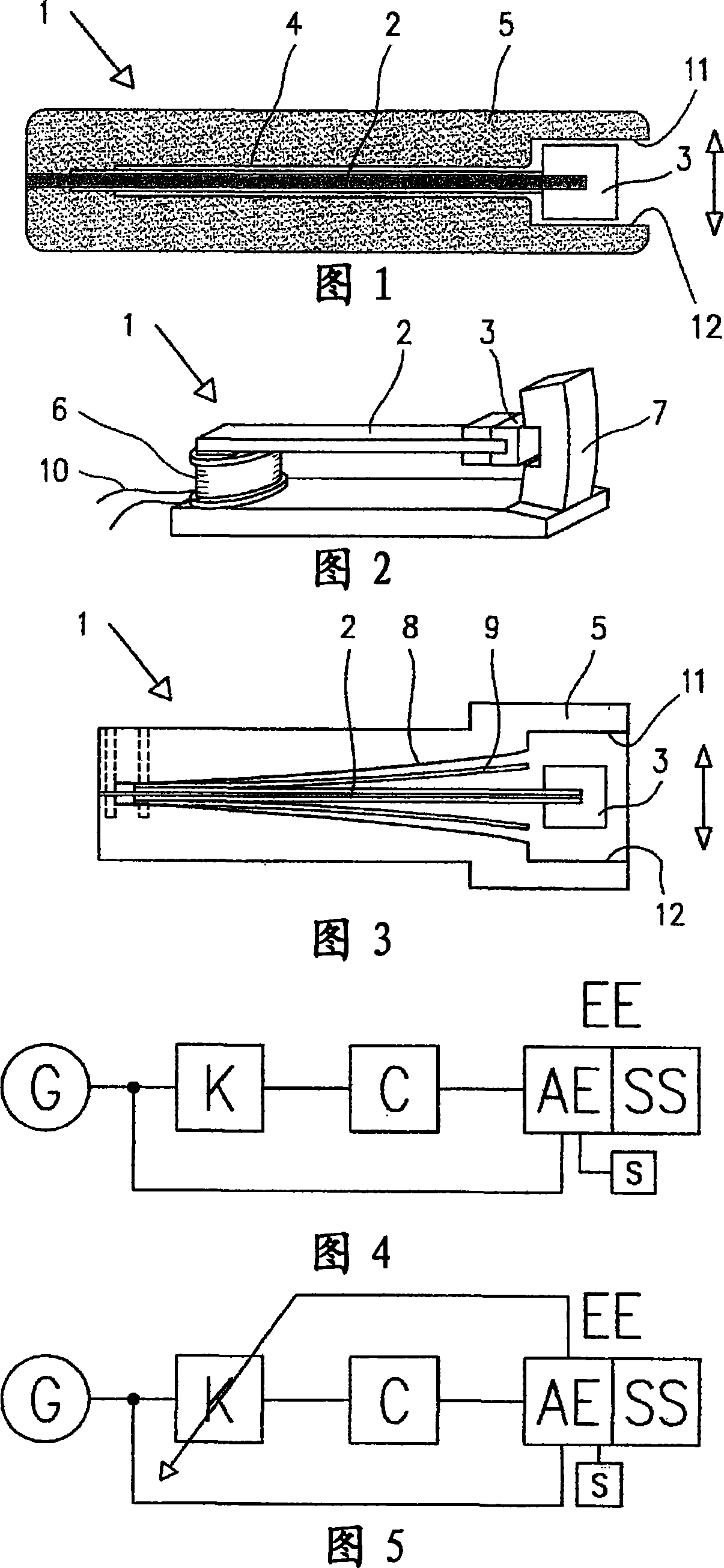

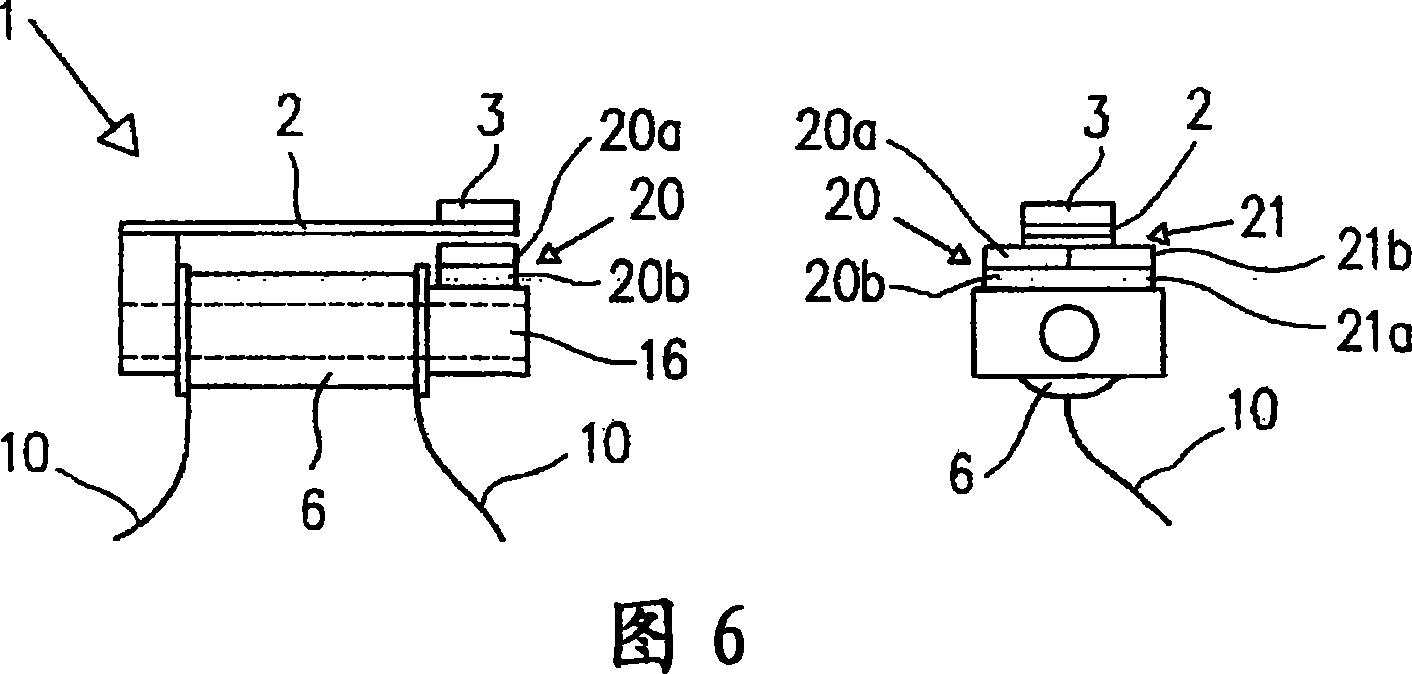

[0027] FIG. 1 shows a section through a tire module 1 which is preferably arranged on the inner side of a pneumatic tire opposite the tread region. The housing part 5 has a groove in which the spring part 2 , which is a leaf spring in the present embodiment, is clamped at one end. At the end of the spring element 2 opposite the clamping end there is a vibrating mass 3 which vibrates as a result of mechanical impulses. The spring part 2 and the seismic mass 3 together form a spring-mass oscillator which moves oscillatingly within the housing 5 . A piezoelectric layer 4 is provided on the top and bottom of the spring element 2, said layer being suitably polarized and equipped with a contact surface. The application is designed such that a deflection of the spring element 2 results in an elongation or compression of the piezoelectric layer 4 . A voltage can be taken from contact surfaces not shown, so that the kinetic energy caused by the oscillating seismic mass 3 can be conve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com