Self-adaptive sounding method and apparatus for electric sounding device

A sounding device and self-adaptive technology, applied in the direction of sounding equipment, instruments, etc., can solve problems such as violation of natural characteristics, affecting sound level, frequency mismatch, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

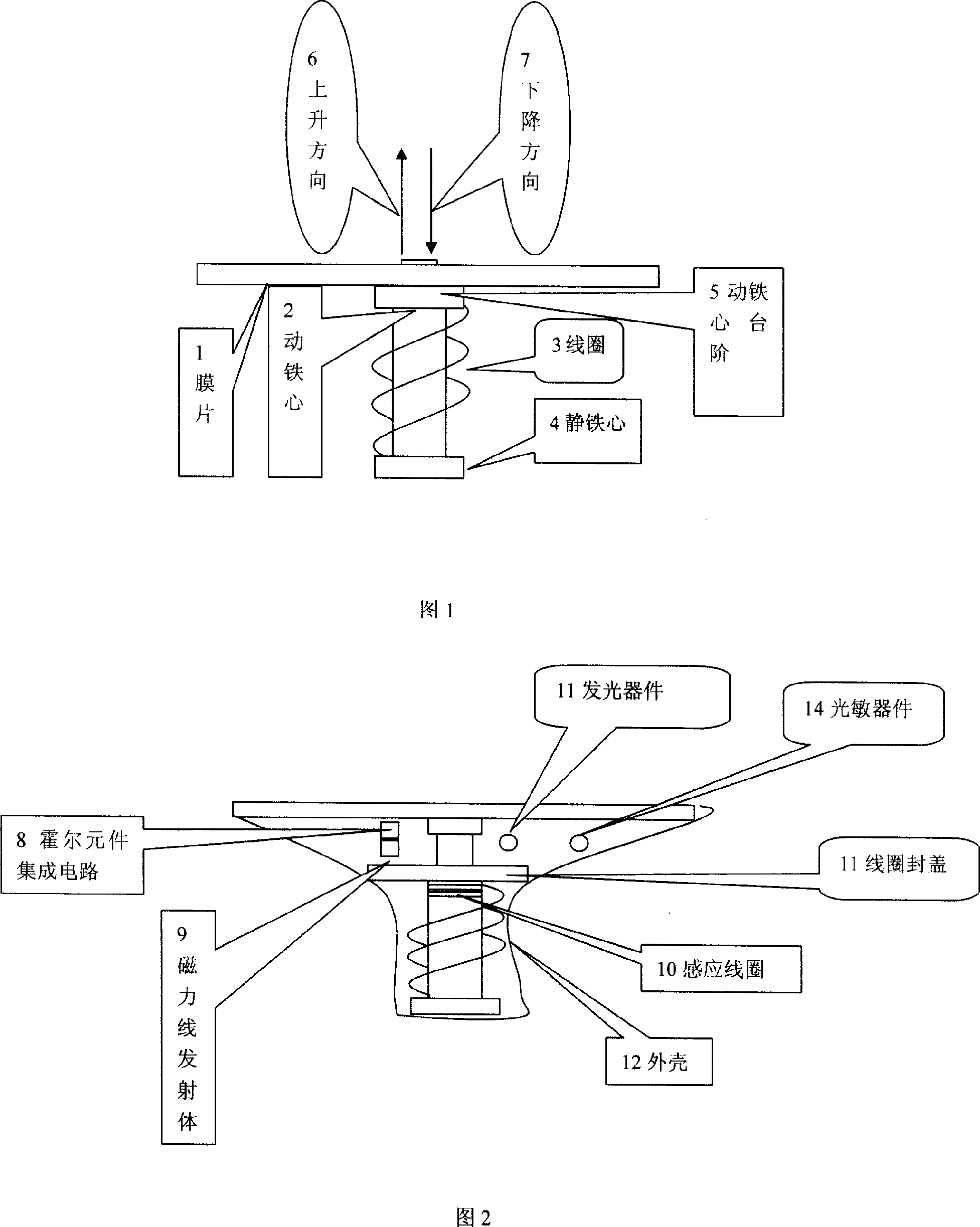

Method used

Image

Examples

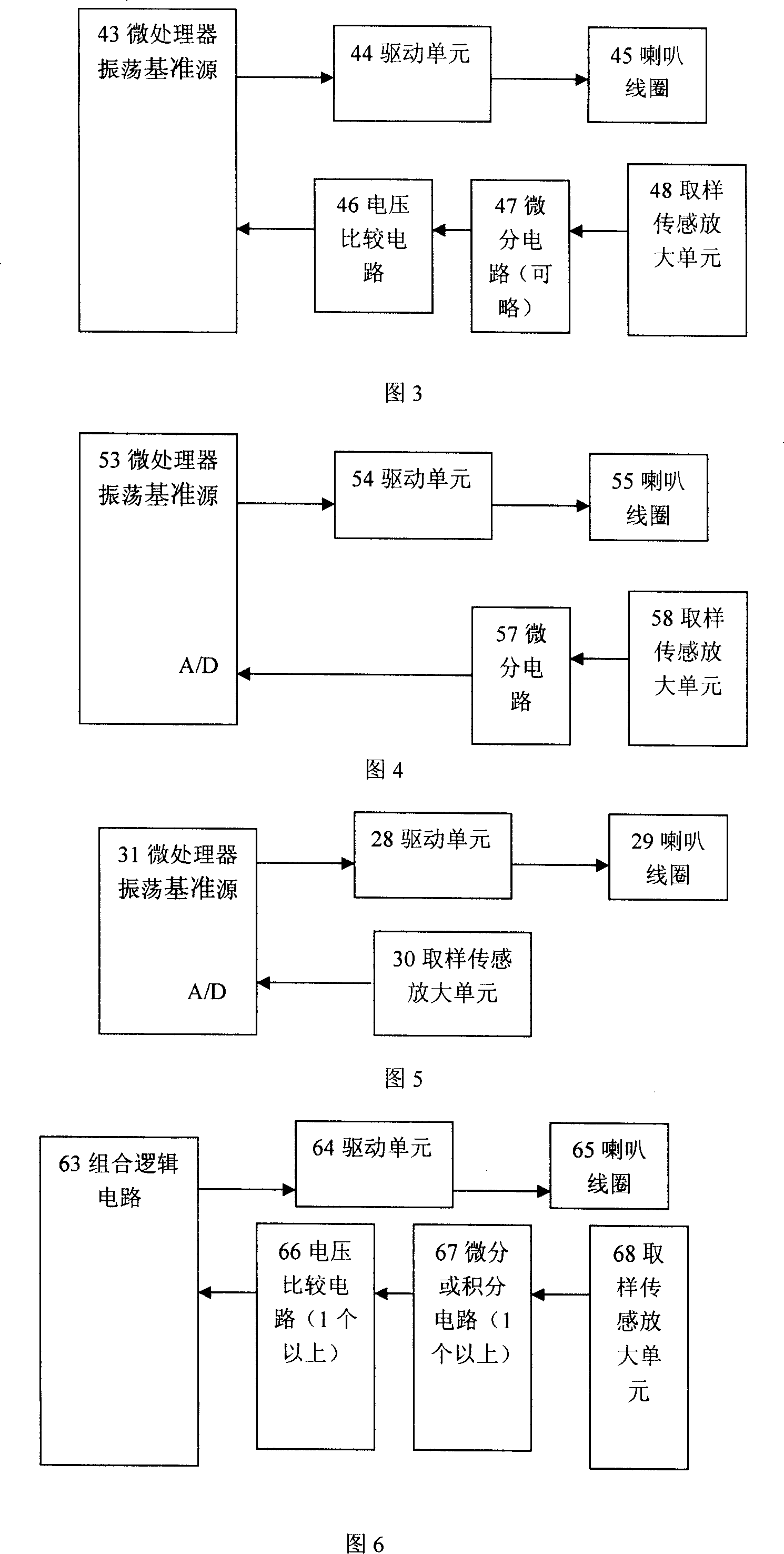

example 1

[0061] Example 1: Aftershock characteristic period method

[0062] The silicon micro-chip microphone integrated circuit is used as the sensor, the single-chip microcomputer has A / D and a comparator, the negative input terminal of the comparator is connected to the zero point voltage output by the sensor, such as 1.1V, and the positive input terminal of the comparator is connected to the output of the sensor; the power supply The voltage sampling uses a voltage divider resistor, so that when the maximum working voltage is reached, the 5v voltage can be divided, and the rated voltage can also be divided into 5v (in this case, if the voltage is greater than the rated voltage, it will not be adjusted, and it will become a conservative value), and more than 100 volts should be avoided. Power supply interference voltage, this voltage divider is connected to the A / D input terminal of the single chip microcomputer. The control terminal is output by the I / O port of the single-chip micr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com