A method for connecting ceramic tesserae

A technology of inlaying blocks and ceramics, applied in ceramic molding machines, inlaid decorative structures, decorative arts, etc., can solve the problem of damaging the quality of the final product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

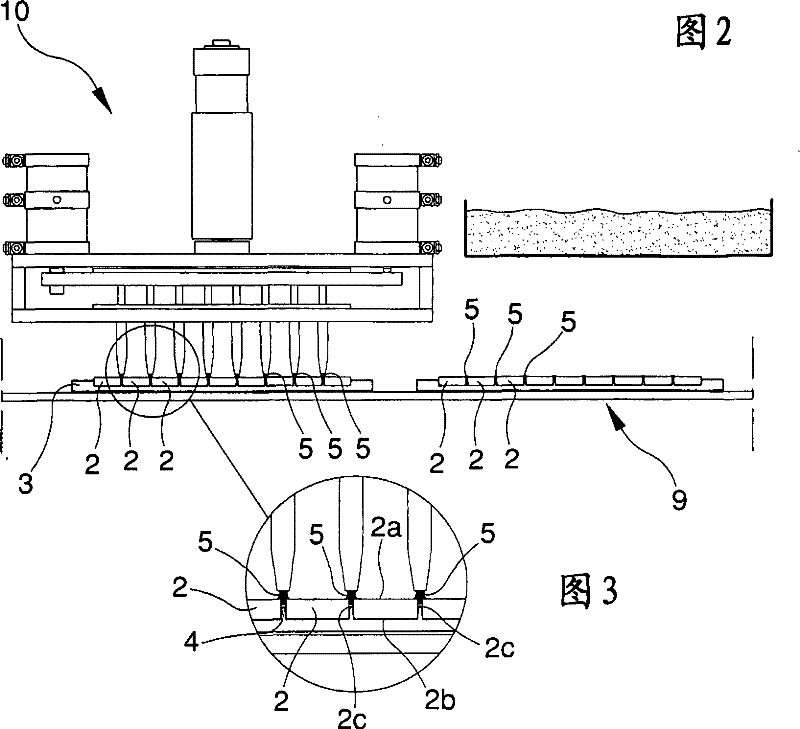

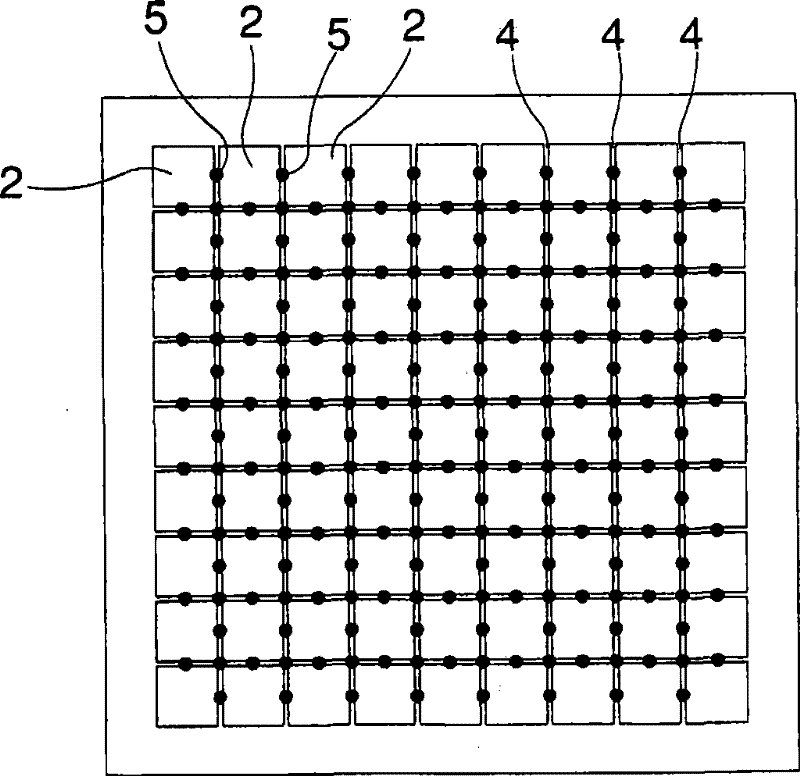

[0018] The ceramic insert 2 shown in the drawings has a laying surface 2a, a surface 2b parallel to and opposite to the laying surface 2a, and a side surface 2c connecting the laying surface 2a with the shown surface 2b. The laying surface 2a, which is not visible when the covering is covered, essentially constitutes the surface at which the slug is placed on the supporting surface of the covering. The surface 2b shown is visible after the covering has been placed.

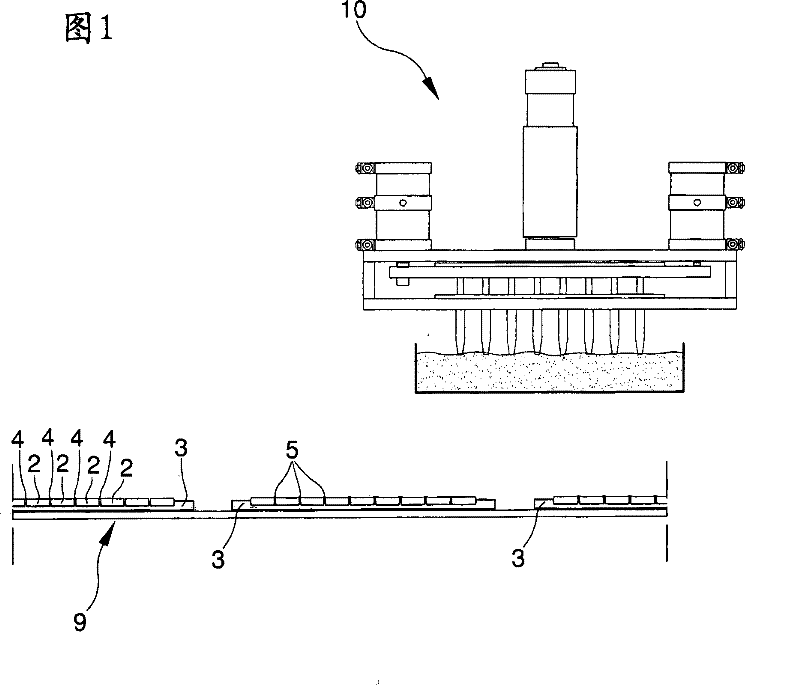

[0019] The method of the invention comprises the step of positioning ceramic slugs 2 in a predetermined order on a support surface 3, wherein the ceramic slugs 2 are separated from each other by spacer lines 4 (also called fugues) having a predetermined width, wherein the slugs are characterized by their The laying surface 2a is positioned facing upwards. The support surface 3 is preferably formed by a base plate provided with recesses for receiving ceramic inserts. The placement of the slugs is preferably linea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com