Direct load bearing type composite insulator, and preparation method

A composite insulator and direct technology, applied in the field of power transmission and transformation, can solve the problems of insufficient reliability, scattered mechanical load test values, poor bearing capacity, etc., and achieve the effect of strong connection stability, enhanced bearing capacity, and good stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing and embodiment the invention will be further described

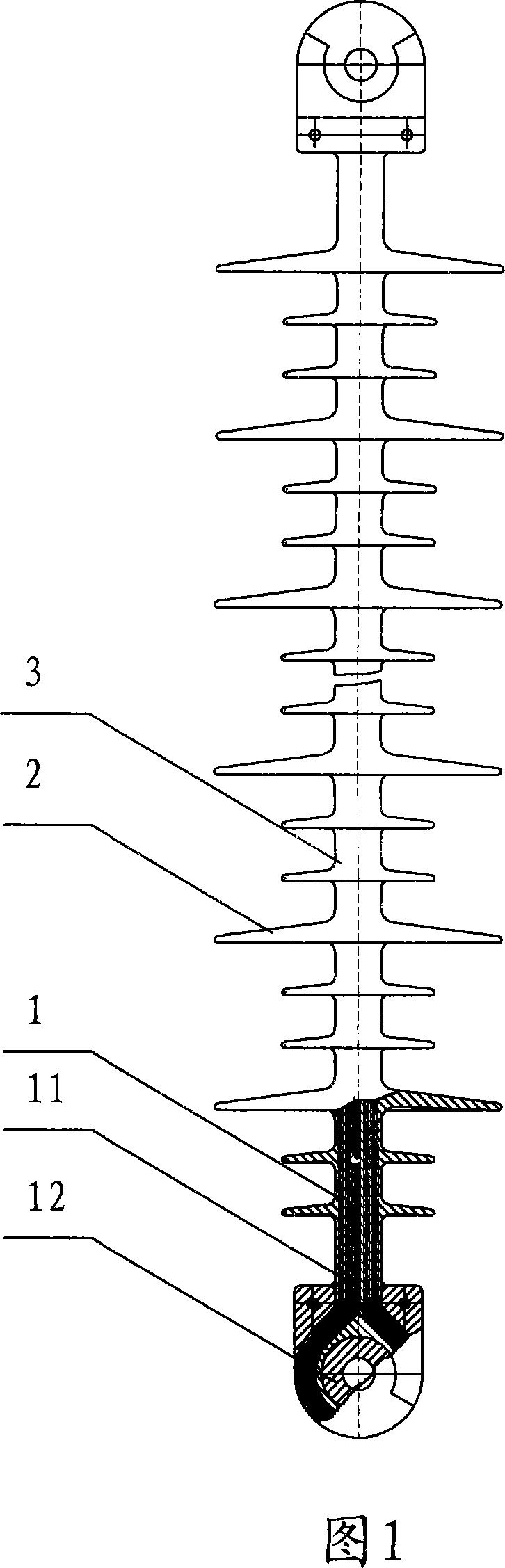

[0025] Please refer to FIG. 1 , a schematic structural diagram of a direct loading composite insulator and a preparation method thereof of the present invention. As shown in Figure 1, a direct loading composite insulator includes a core 1 and an end attachment 12 connected to the end of the core 1, the core 1 is made of glass fiber bundles 11 bonded and wrapped by silicone rubber The outside of the connecting body between the core body 1 and the end attachment 12 is formed as a whole by wrapping silicon rubber. The connection between the core body 1 and the hanging ring 12 is realized by the way that the glass fiber bundle 11 in the core body 1 wraps around the hanging ring 12 . The sheath 3 and the shed 2 are of an integrated structure, which is made by silicone rubber injection process.

[0026] A method for preparing a direct load-bearing composite insulator of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com