Online method for testing model of industrial unstable time lag procedure

A process model and a stable technology, applied in the field of detection, can solve the problems that have not been completely solved, and the accuracy of model detection is poor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

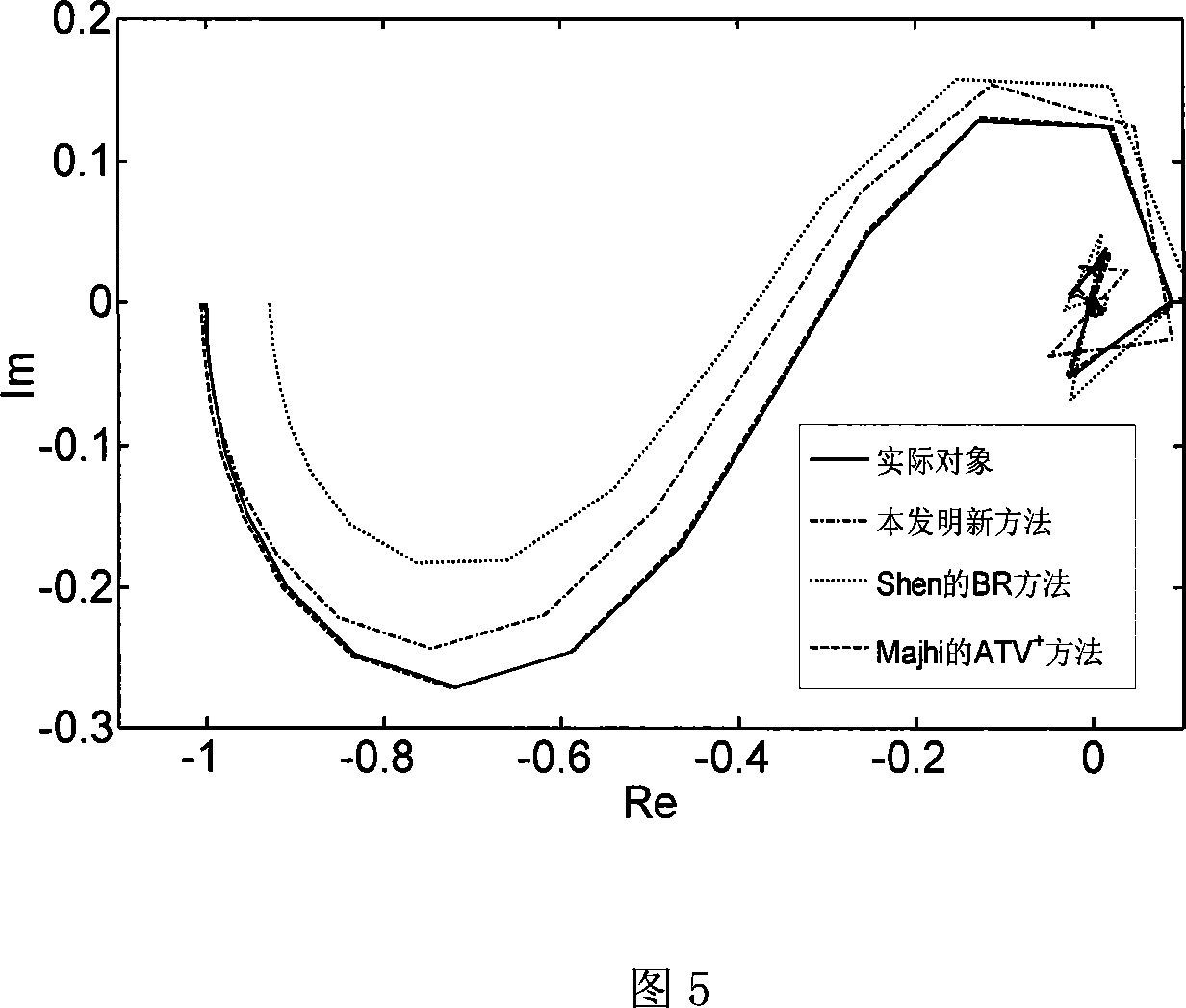

[0053] Embodiment: This embodiment is aimed at an object, assuming that its dynamic characteristics will be affected by external perturbation and will change during the self-tuning control process of the system. Part of the method for analyzing and calculating system model parameters in this embodiment can be programmed, and the compiled program is installed in the device in advance.

[0054] For a chemical boiler drum water level object, the dynamic characteristics are as follows:

[0055] 1 s - 1 e - 0.4 s

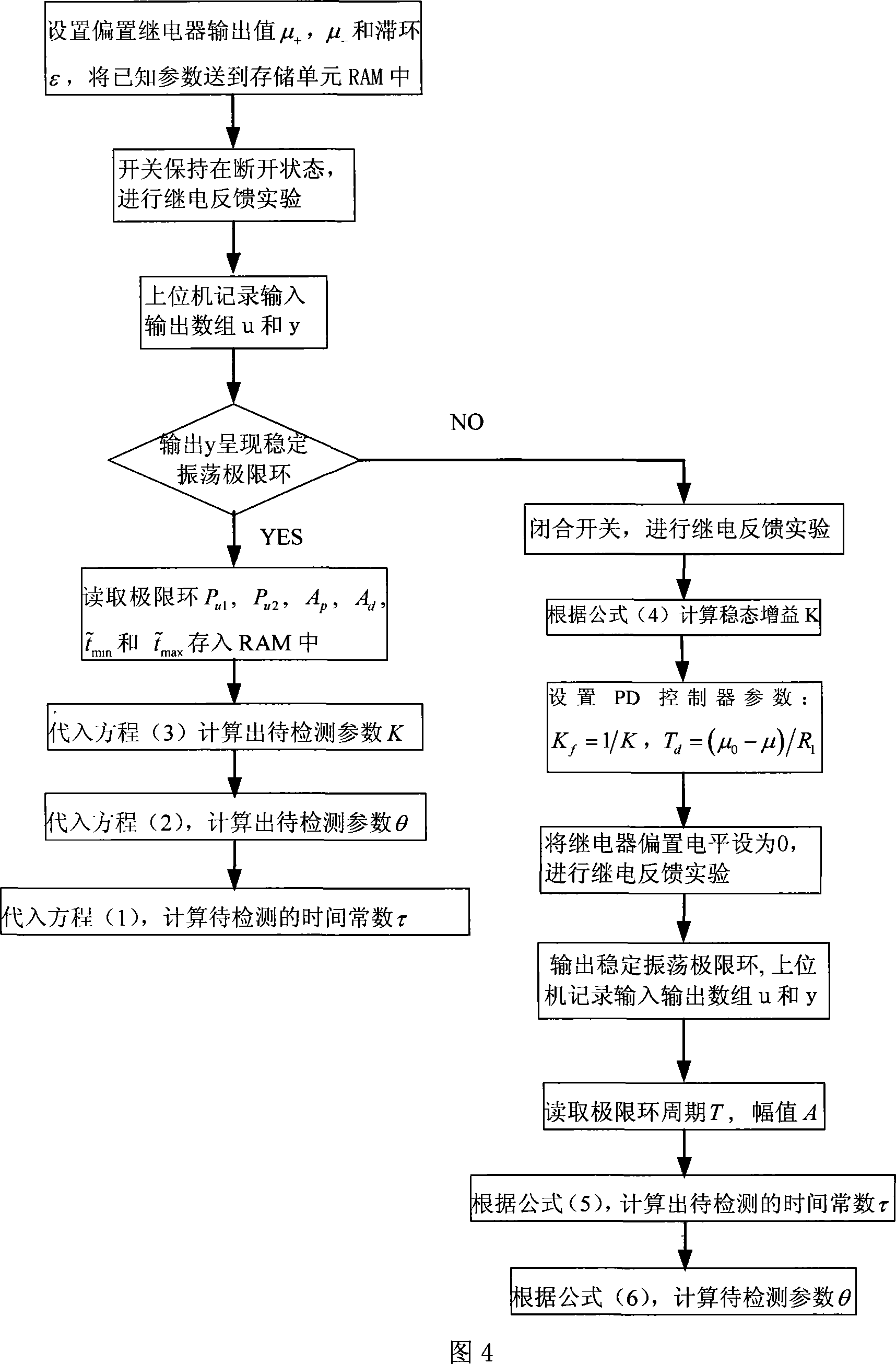

[0056] Application of the model detection method provided by the present invention, the specific implementation process is as shown in Figure 4:

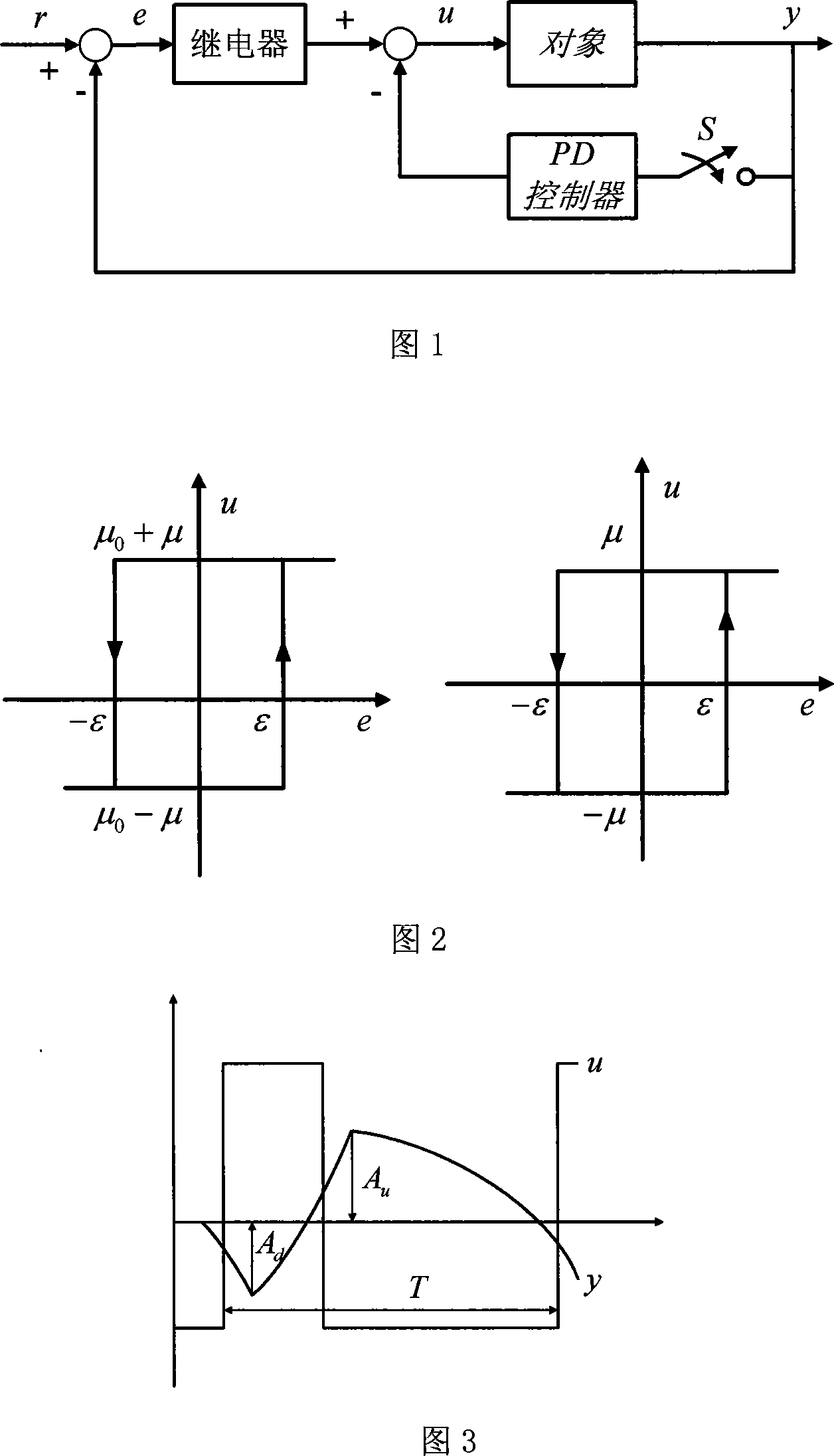

[0057] Step 1: Build a relay feedback test system according to the structure diagram shown in Figure 1; the input and output characteristics of the bias re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com