Preprocess system of garbage power

A waste-to-energy and pre-treatment technology, applied in combustion methods, combustion types, incinerators, etc., can solve the problems of reducing the economic benefits of enterprises, unstable combustion, high waste humidity, etc., to improve stability and power generation efficiency, and is conducive to The effect of full combustion and reduction of treatment methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

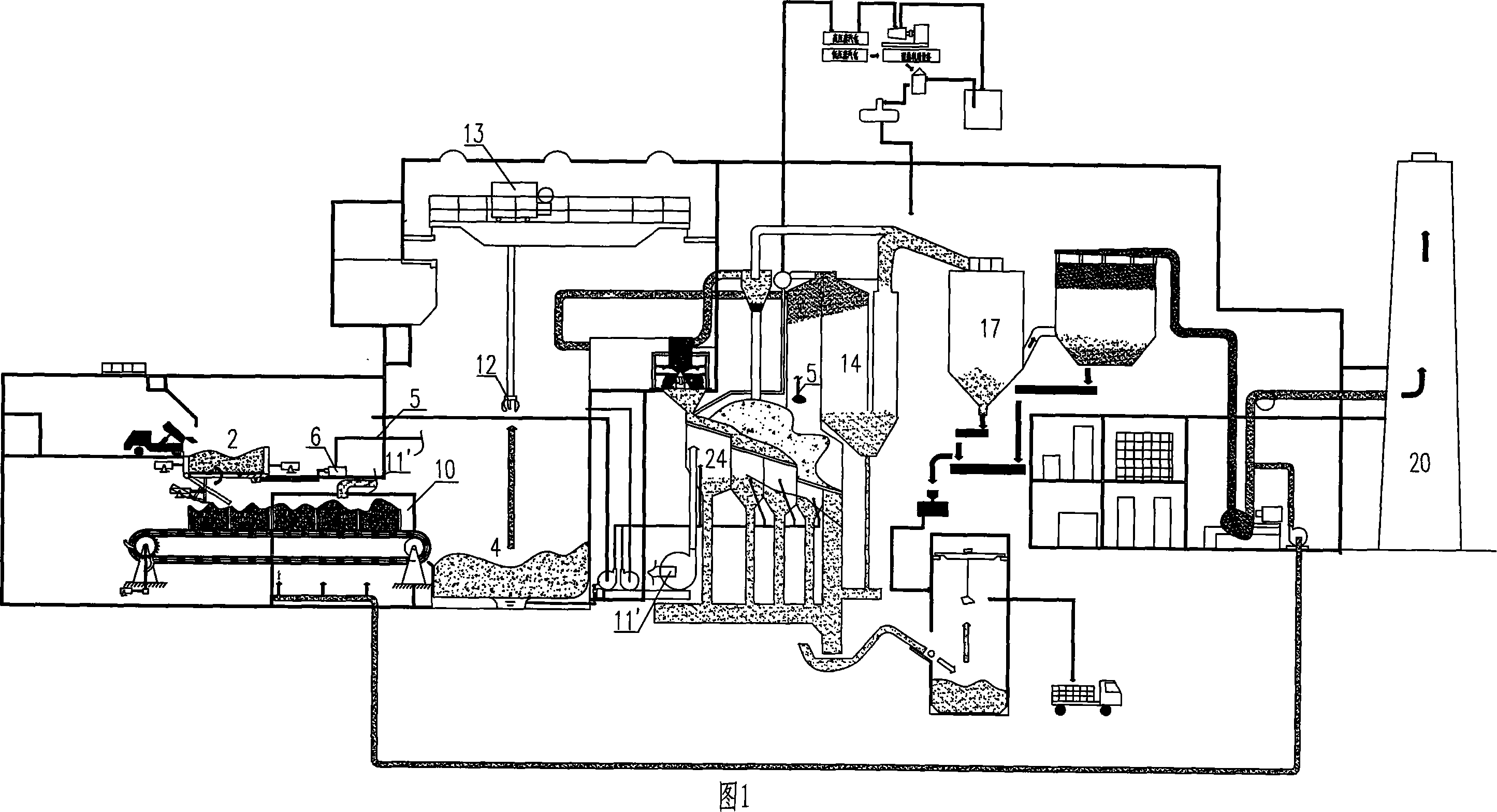

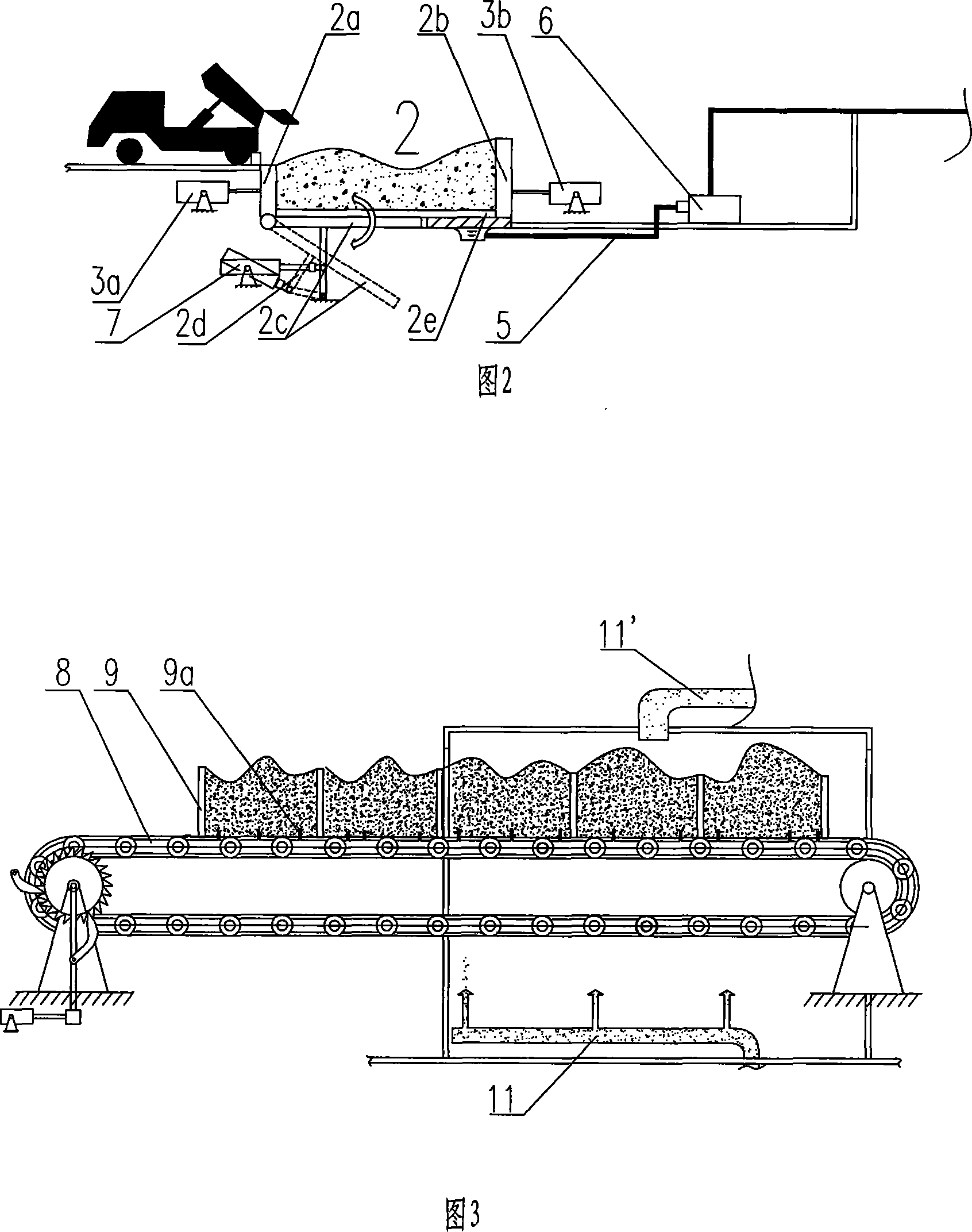

[0023] As shown in Figure 1, Figure 2, and Figure 3: a waste-to-energy pretreatment system consists of a waste storage pit 4, a waste operating mechanism, a preheating section fire grate 24, a combustion furnace 14, a gas dust collector 17, a chimney 20, and an extrusion system. Composed of drying mechanism and pre-drying grate mechanism,

[0024] Wherein the garbage storage pit 4 is connected with the preheating section fire grate 24 through the garbage operation mechanism, the output port of the preheating section fire grate 24 is connected with the input port of the combustion furnace 14, and the combustion waste gas outlet port of the combustion furnace 14 The pipeline communicates with the waste gas inlet port of the gas dust collector 17, and the outlet port of the gas dust collector 17 communicates with the chimney 20; wherein ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com