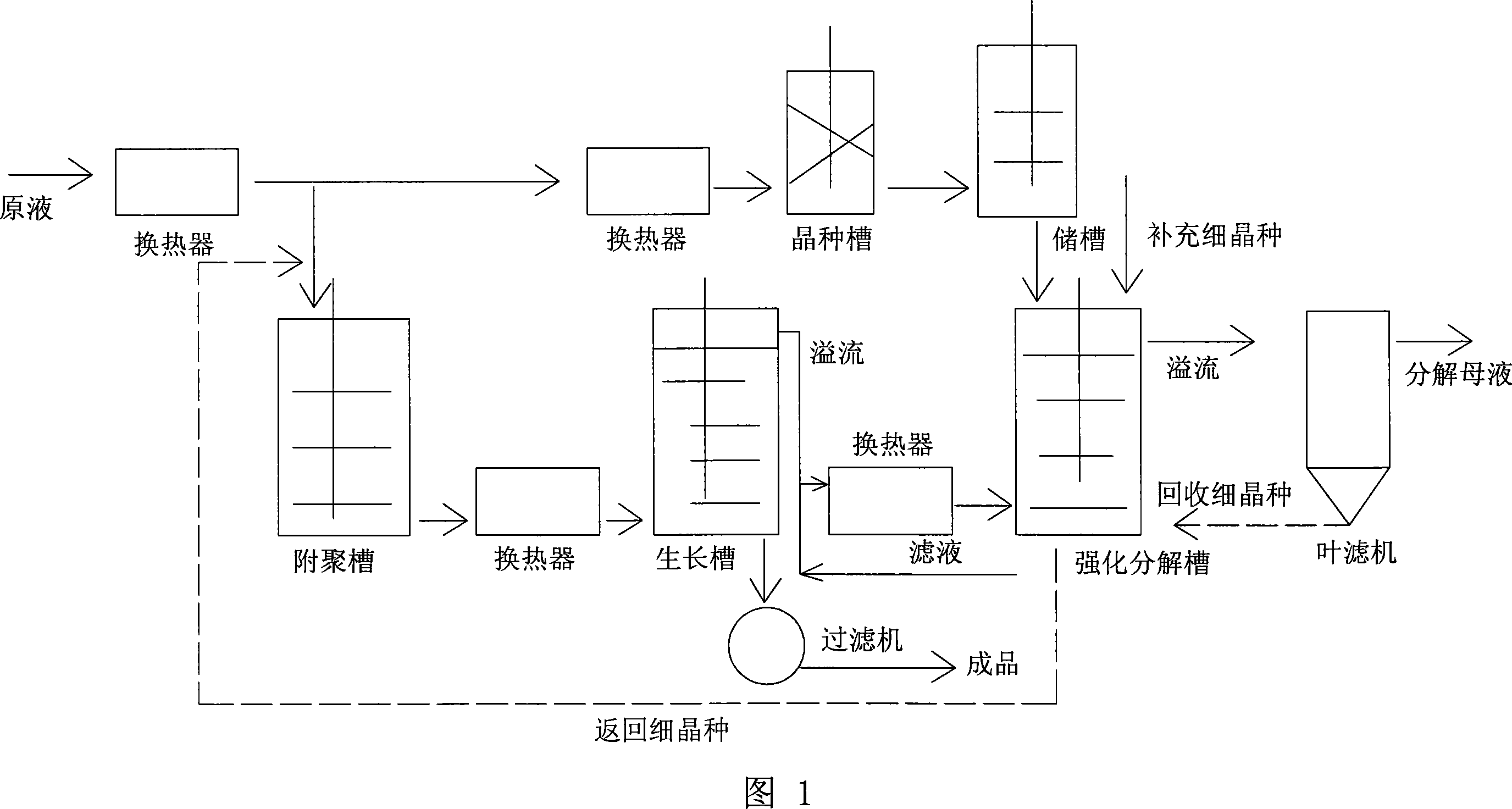

Three stages, two seeds technique of seed crystal decomposition

A seed and process technology, applied in the field of three-stage two-seed separation and decomposition process, can solve the problem of not being industrially applied, and achieve the effects of high strength, excellent product quality and saving power consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] The three-stage two-seed decomposition process of the present invention divides the seed separation process into four parts: agglomeration decomposition section, seed crystal growth decomposition section, secondary nucleation control and enhanced decomposition. Specific process parameters: seed crystal tank temperature 50°C , the agglomeration tank temperature is 70°C, the seed ratio is 0.35, the seed growth and decomposition tank temperature is 60°C, the seed crystal fineness is 70 μm, the seed crystal amount is 500g / l, and the seed ratio is 2.5; the enhanced decomposition tank temperature is 50°C, and the seed crystal fineness 25μm, the seed crystal amount is 500g / l, and the decomposition rate is 58.5%.

Embodiment 2

[0070] The three-stage two-seed decomposition process of the present invention divides the seed separation process into four parts: agglomeration decomposition section, seed crystal growth decomposition section, secondary nucleation control and enhanced decomposition. Specific process parameters: seed crystal tank temperature 50°C , agglomeration tank temperature 65°C, seed ratio 0.40, seed crystal growth decomposition tank temperature 60°C, seed crystal fineness 70μm, seed crystal volume 500g / l, seed ratio 3.0; enhanced decomposition tank temperature 45°C, seed crystal fineness 20μm, the seed crystal amount is 600g / l, and the decomposition rate is 59.5%.

Embodiment 3

[0072] The three-stage two-seed decomposition process of the present invention divides the seed separation process into four parts: agglomeration decomposition section, seed crystal growth decomposition section, secondary nucleation control and enhanced decomposition. Specific process parameters: seed crystal tank temperature 50°C , agglomeration tank temperature 60°C, seed ratio 0.40, seed crystal growth decomposition tank temperature 60°C, seed crystal fineness 60μm, seed crystal volume 600g / l, seed ratio 3.5; enhanced decomposition tank temperature 45°C, seed crystal fineness 18μm, the seed crystal amount is 600g / l, and the decomposition rate is 60.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com