Dust-proof electric cabinet

An electrical cabinet and dust-proof technology, which is applied in the field of electrical cabinets, can solve the problems of difficult disassembly of the filter screen, dust entering the electrical cabinet, and reduced cooling effect, so as to achieve the effect of improved heat dissipation and ventilation, and good dust removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

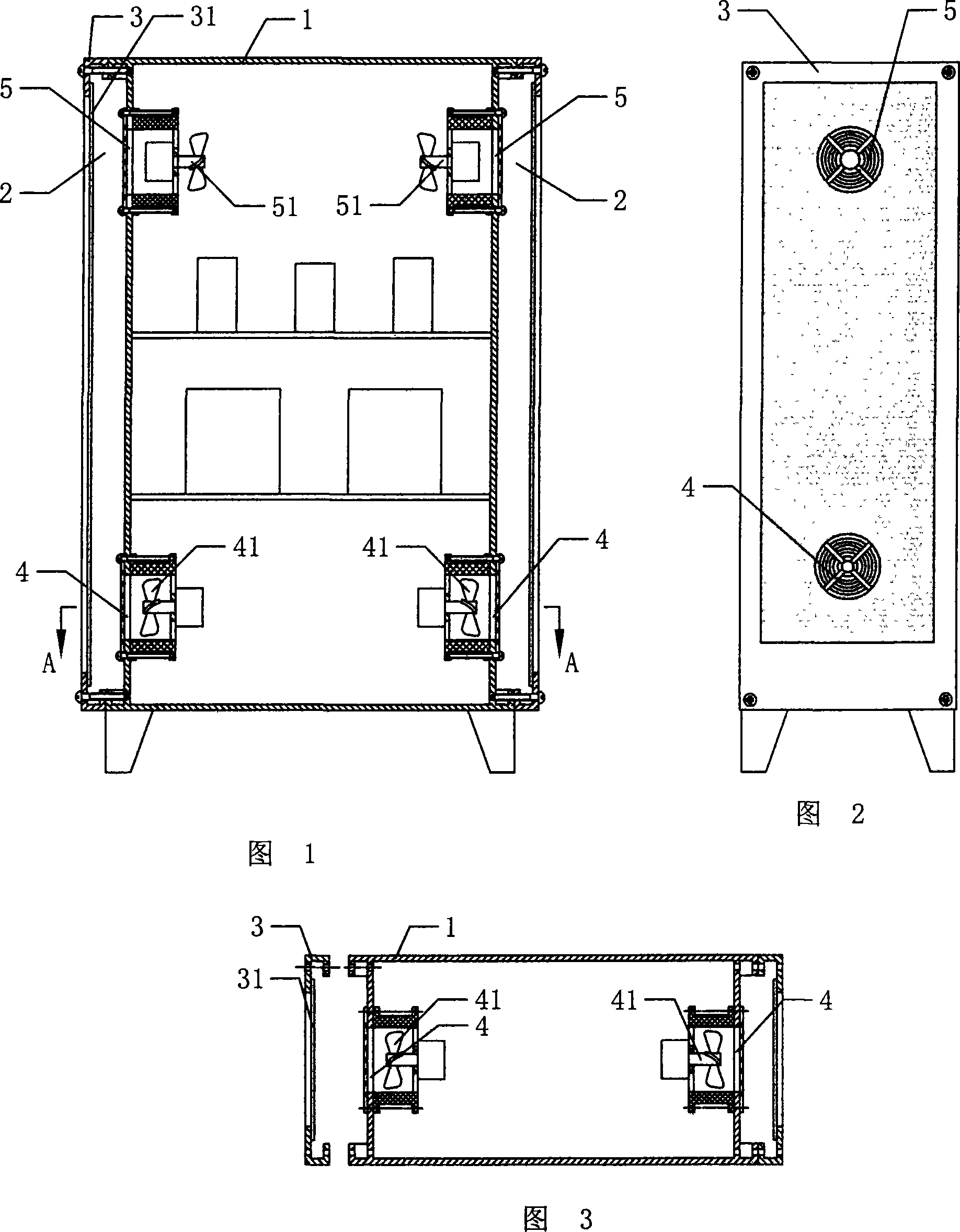

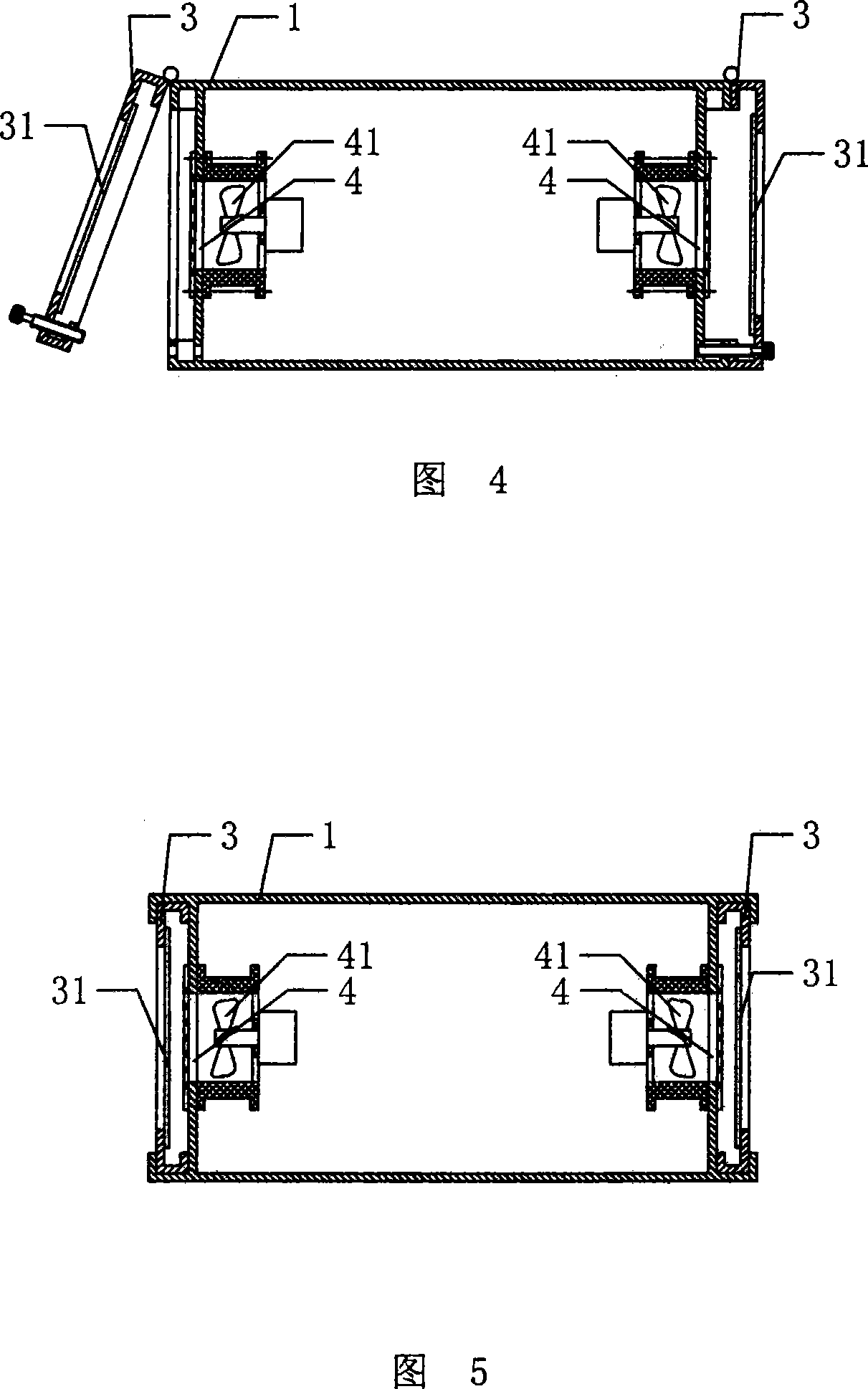

[0025] Embodiment 1: As shown in Figure 1, Figure 2 and Figure 3, the dust-proof electrical cabinet includes an electrical cabinet housing 1, a ventilation device arranged on the side wall of the electrical cabinet housing 1, and the housing 1 The side wall provided with the ventilation device has a ventilation cavity 2 communicated with the ventilation device, and the side wall of the ventilation cavity 2 is equipped with a ventilation cavity 2 communicating with the outside space. filter device. The air exchange cavity 2 is a cavity formed by the outward extension of the side wall of the shell 1 for air exchange; Net support 3, described filter net support 3 is provided with filter screen 31, and described filter screen support 3 is fixed on the side wall of described housing 1 by four screws, can be arranged on described filter net 31 like this When there is a lot of dust or damage, the filter screen support 3 can be removed in time to clean or replace the filter screen 31...

Embodiment 2

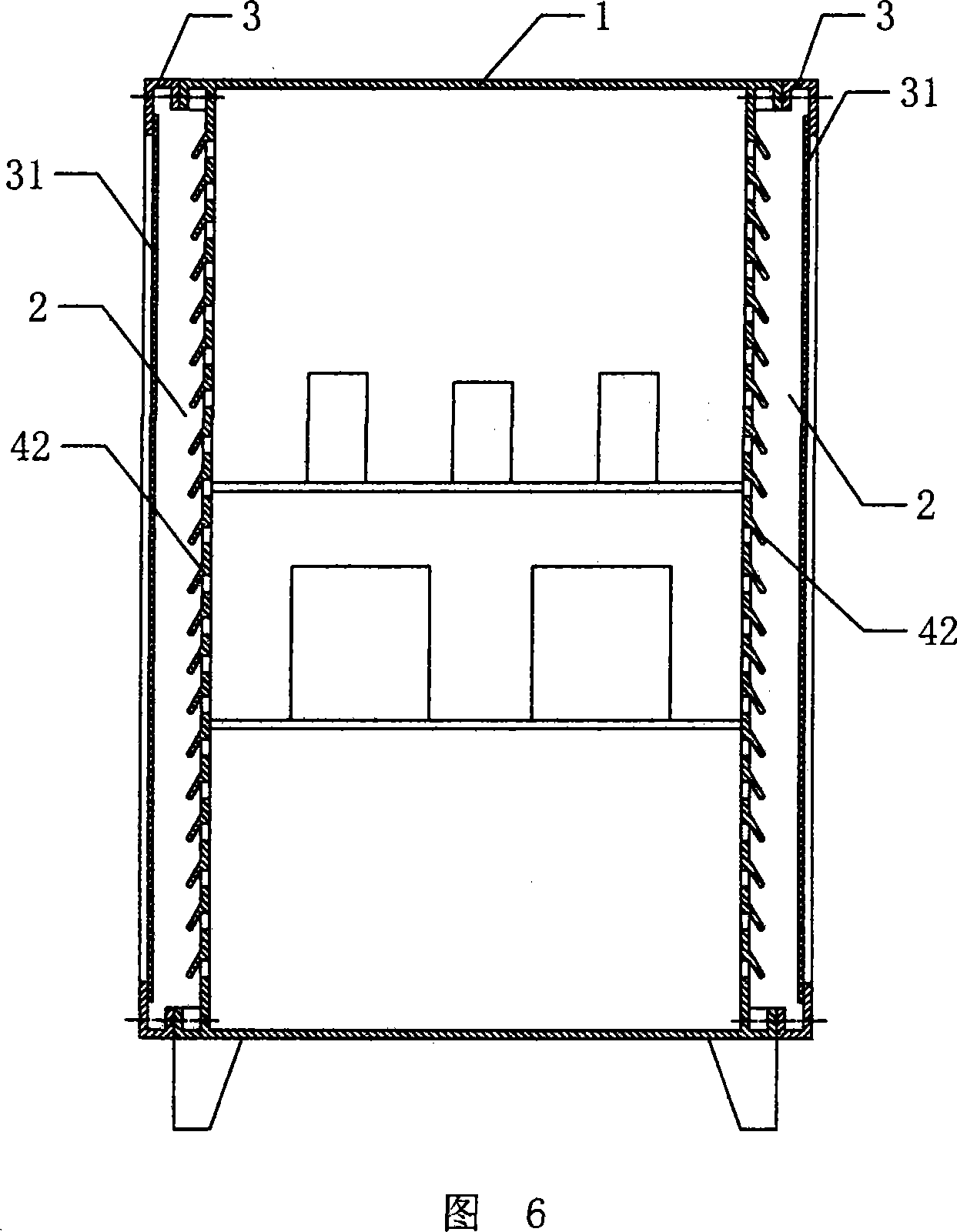

[0028] Embodiment 2: As shown in FIG. 6, the basic structure of the dust-proof electrical cabinet is basically the same as that of Embodiment 1, the difference is that the ventilation device is several hundreds of valves arranged on the two side walls of the housing 1. Page window 42, that is, the ventilation device described is a natural ventilation device. In an electrical cabinet that generates less heat, setting this ventilation device can save the power used for installing fans, etc., and can make the structure simple and the cabinet The inner space becomes larger, and the maintenance cost caused by fan failure and other problems is also saved.

Embodiment 3

[0029] Embodiment 3: As shown in FIG. 7 , the basic structure of the dust-proof electrical cabinet is basically the same as that of Embodiment 1, the difference is that the ventilation device includes an air inlet 4 arranged at the lower end of the side wall of the housing 1 , the air intake fan 41 fixedly installed at the air inlet 4, and a number of shutters 42 arranged on the upper ends of the two side walls of the housing 1. This kind of ventilation device enters the air through the air inlet 4 and enters the electrical cabinet. After sufficient heat exchange in the cabinet, the air in the cabinet is discharged through the louvers 42 on the upper ends of the two side walls of the housing 1 under the pressure of the air intake fan 41, which meets the requirements when the electrical cabinet generates more heat. , can get heat exchange in time, and increase the internal space of the electrical cabinet to a certain extent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com