Temp lowering device for deep mine

A cooling device, deep mining technology, applied in mining equipment, ventilation of mines/tunnels, earthwork drilling, etc., can solve the problem of high system investment and operating costs, and achieve low system investment and operating costs, high efficiency, and conveying capacity. less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

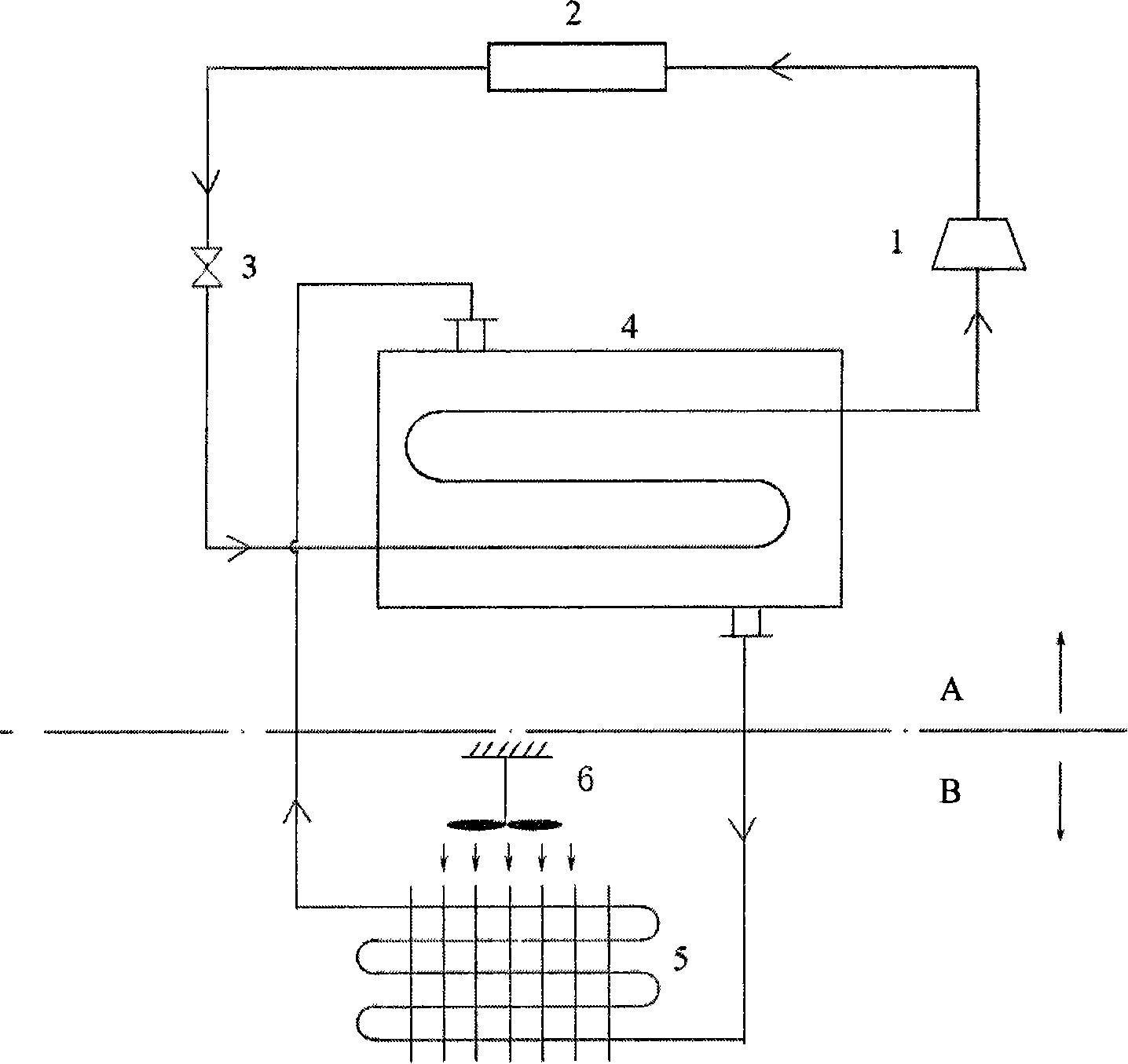

[0026] A cooling device for deep mining mines according to the present invention is composed of two parts: a surface unit A and an underground unit B. The underground unit B consists of a heat exchanger 5 and a blower 6; the ground unit A includes a compressor 1, a condenser 2, an expansion valve 3, and an evaporation condenser 4. The inlet of compressor 1 is connected to the outlet of evaporative condenser 4, the outlet of compressor 1 is connected to the inlet of condenser 2, the outlet of condenser 2 is connected to the inlet of expansion valve 3, and the outlet of expansion valve 3 is connected to evaporative condenser 4 The inlet of the evaporative condenser 4 is connected to the inlet of the compressor 1. The bottom heat exchange working medium outlet of the evaporative condenser 4 is connected with the inlet of the downhole heat exchanger 5 through a connecting pipe, and the outlet of the downhole heat exchanger 5 is connected with the top heat exchange working medium i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com