Organic light emitting device

A technology of organic light-emitting device and light-emitting layer, applied in the field of OLED, can solve problems such as difficulty in hole injection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

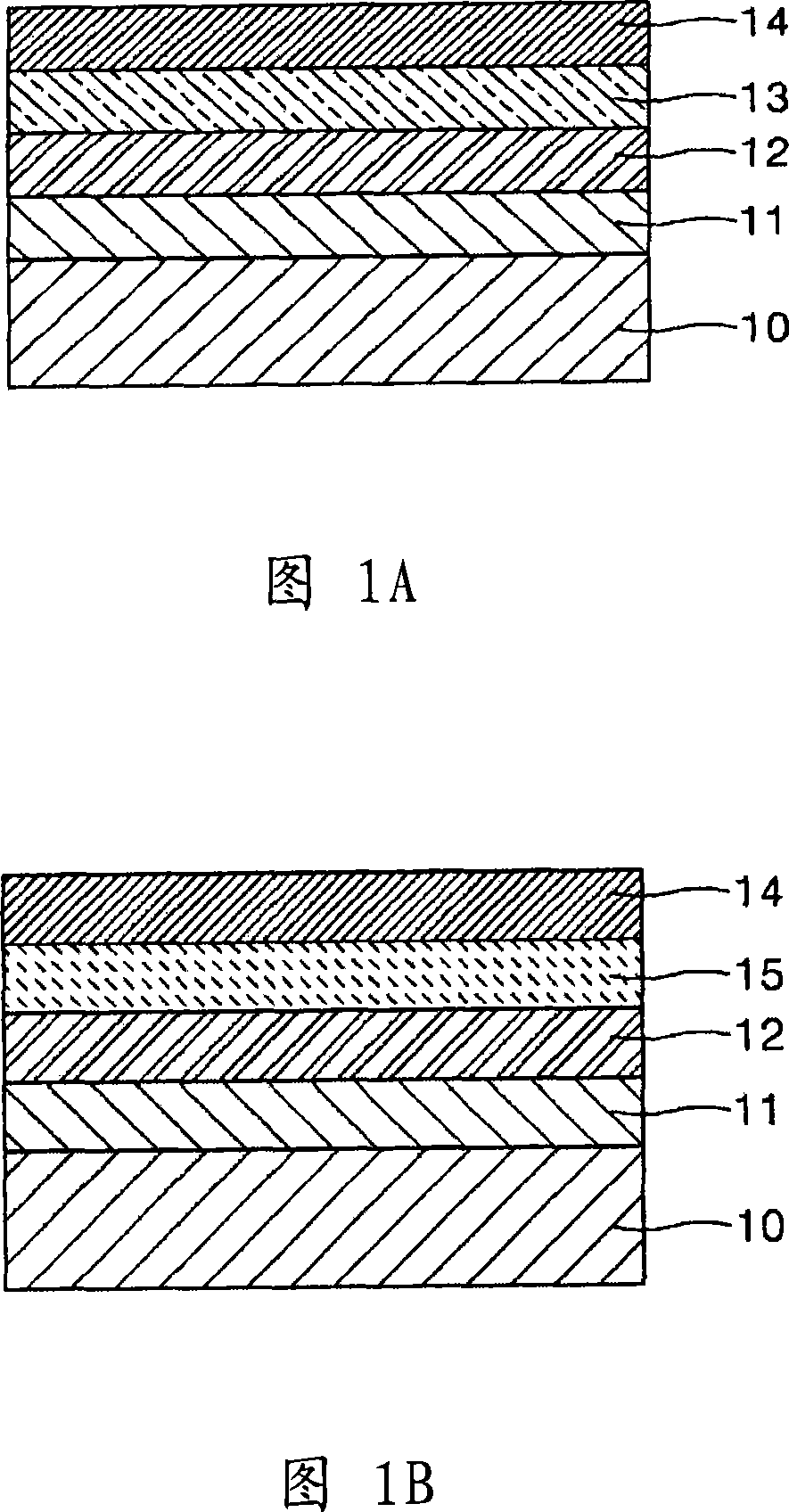

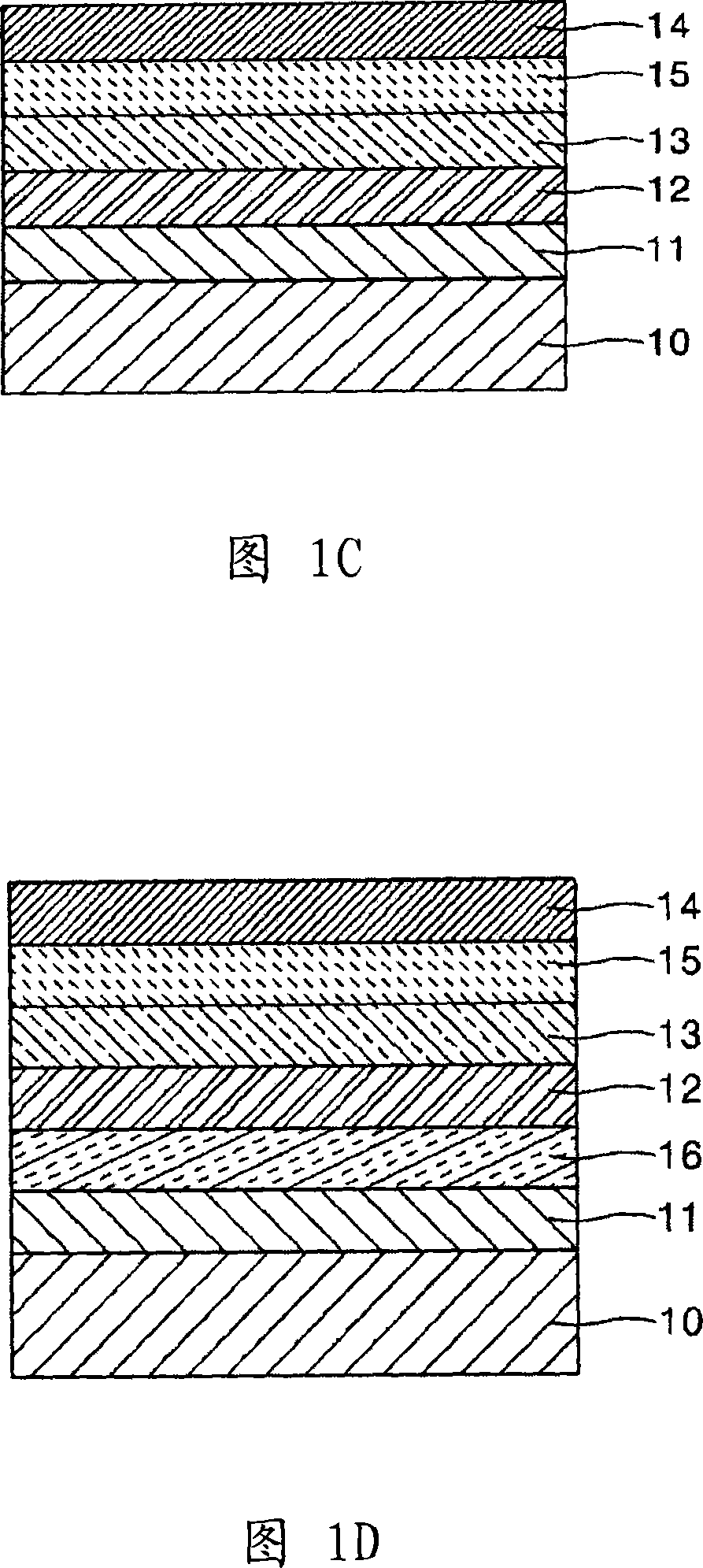

Method used

Image

Examples

preparation Embodiment 1

[0208] Preparation Example 1: Polyaniline (PANI) Conductive Polymer Composition

[0209] Polystyrenesulfonic acid-graft-polyaniline (PSSA-g-PANI) was polymerized as a self-doping conductive material using the known synthetic method of [W.J.Bae et al., Chem. Comm., pp2768-2769, 2003]. In this embodiment, the weight ratio of PSSA polymer chains and grafted PANI chains is 1:0.15. The number average molecular weight of PSSA-g-PANI was 35,000. This material was melted in water to 1.0% by weight. Then, a perfluorinated ionomer (PFI) was purchased from Aldrich Co., dispersed to 5 wt% in a solvent with a water to alcohol volume ratio of 0.45:0.55, and isopropanol and 5 wt% PFI at 1.0 wt% The PSSA-g-PANI solution was mixed and used as the material to form HIL 11. This sample is referred to as Sample A.

[0210] [Formula 14]

[0211]

[0212] (where x=1300, y=200, x=1)

preparation Embodiment 2

[0213] Preparation Example 2: Preparation of PEDOT-PSS / PFI Conductive Polymer Composition

[0214] PEDOT-PSS (model: Baytron P VP A14083) from H.C. Starck, a subsidiary of Bayer Aktien AG, was purified to control the Na and sulfate content to 5 ppm or less. Then, PFI of formula 14 was purchased from Aldrich Co. dispersed to 5 wt% in water and alcohol. Then, HIL 11 with each different composition of PEDOT-PSS was prepared. The proportions of this composition are listed in Table 1 below.

[0215] [Table 1]

[0216] sample code

Embodiment 1

[0217] Evaluation Example 1 - Work Function Evaluation of Conductive Polymer Films

[0218] The conductive polymer compositions obtained in Preparation Examples 1 and 2 were spin-coated on an ITO substrate to form a thin layer to a thickness of 50 nm, and heated on a hot plate in air at 200° C. for 5 minutes, and the conductive polymer was evaluated The work function of the composition. Surface Analyzer Model AC2 as a photoelectron spectrometer in air (PESA) manufactured by RIKEN KEIKI, Co., Ltd. was used as an evaluation apparatus. Sample A shows a work function of 5.6 eV, sample B shows a work function of 5.55 eV, sample C shows a work function of 5.63 eV, sample D shows a work function of 5.72 eV, and sample E shows a work function of 5.79 eV, and sample F showed a work function of 5.95 eV.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com