Drill platform power management system

A power management and drilling platform technology, applied in drilling equipment, signal transmission system, electrical signal transmission system, etc., can solve problems such as poor fuel economy and unit overload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

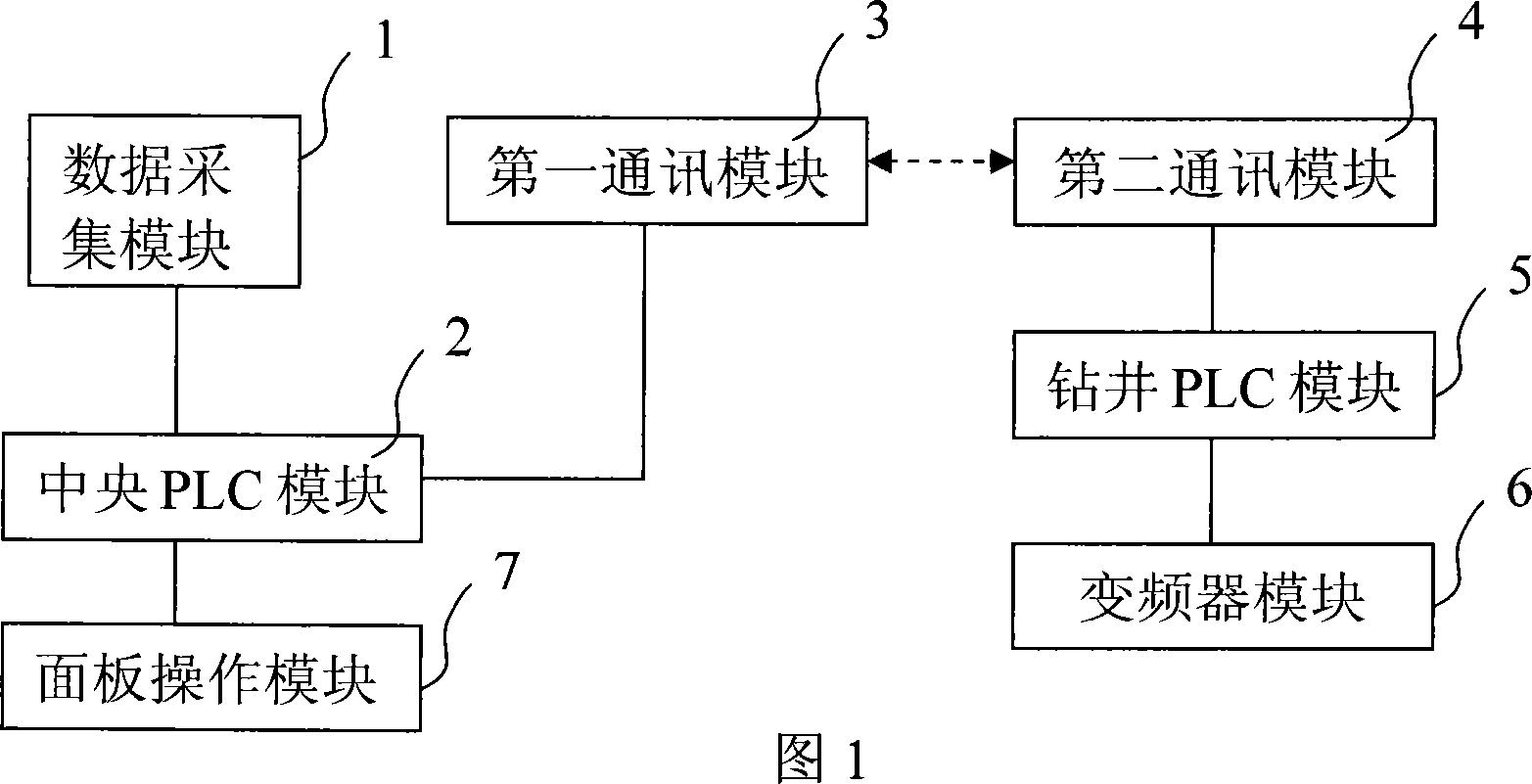

[0013] As shown in Figure 1, the present invention comprises: data acquisition module 1 (5), central PLC module 2, first communication module 3, second communication module 4, drilling PLC module 5, frequency converter module 6 panel operation module 7; The data acquisition module 1 is connected to the first communication module 3 through the central PLC module 2 , and the second communication module 4 is connected to the frequency converter module 6 through the drilling PLC module 5 .

[0014] The data acquisition module 1 is set on the incoming line circuit breaker of each generator set, and is used to collect parameters such as current and voltage of the motor running on site, and transmit the collected parameters to the central PLC module 2 . The data collection modules 1 can be set according to specific conditions, for example, five are set.

[0015] The central PLC module 2 is used to calculate the parameters collected from the data acquisition module 1, and compare them...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com