Method and system for separating ethanol based on sweet sorghum stalk solid ferment material

A solid-state fermentation and fermented material technology, applied in the field of distillation-rectification coupling, can solve the problems of low efficiency of brewing process, long fermentation cycle, high cost of raw material pretreatment, etc., and achieve the effect of preventing ethanol loss, reducing energy consumption and realizing waste heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

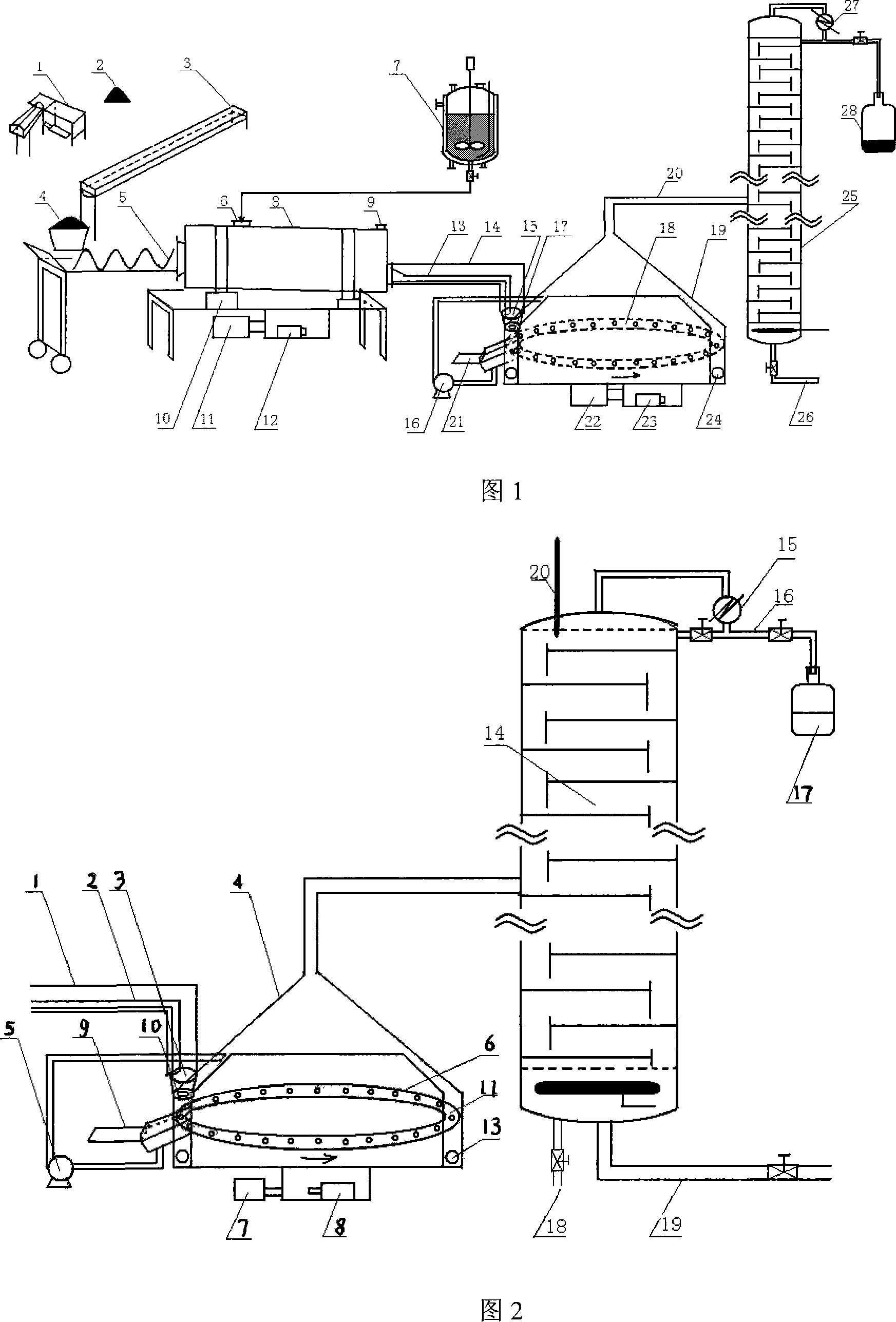

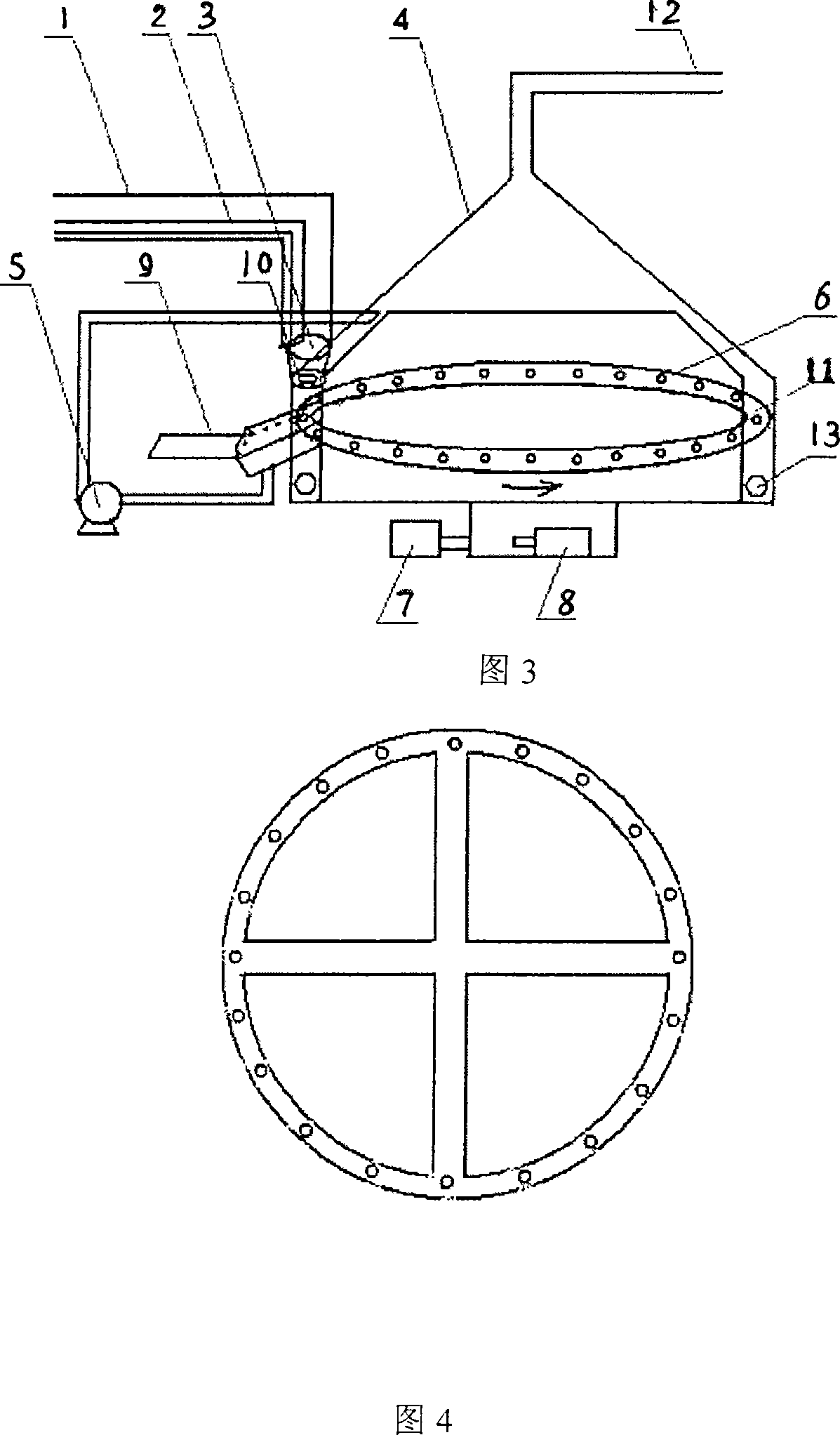

[0032] Below in conjunction with accompanying drawing and embodiment the technical scheme of the present invention is described further:

[0033] The technical scheme adopted in the present invention is: the technology and equipment for continuous separation of ethanol from solid-state fermentation materials include the following procedures and supporting equipment:

[0034] (1) Sealed transportation of fermented material: The solid-state fermentation system directly performs solid-state fermentation on the mature sweet sorghum stalk crushed material; the fermented material is conveyed through a closed tunnel belt to prevent ethanol volatilization;

[0035] (2) Continuous feeding and discharging and solid-state distillation: By adopting a solid-state distillation system with a sealed annular porous rotating disc, the fermentation material can be continuously moved in and the dregs can be continuously removed, and the efficient separation of ethanol and dregs can be realized;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com