Method for producing ethanol by wild plant starch resource as acorn starch for substituting for grain

A technology of wild plant starch and acorn starch, applied in the field of utilization of wild plant starch resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

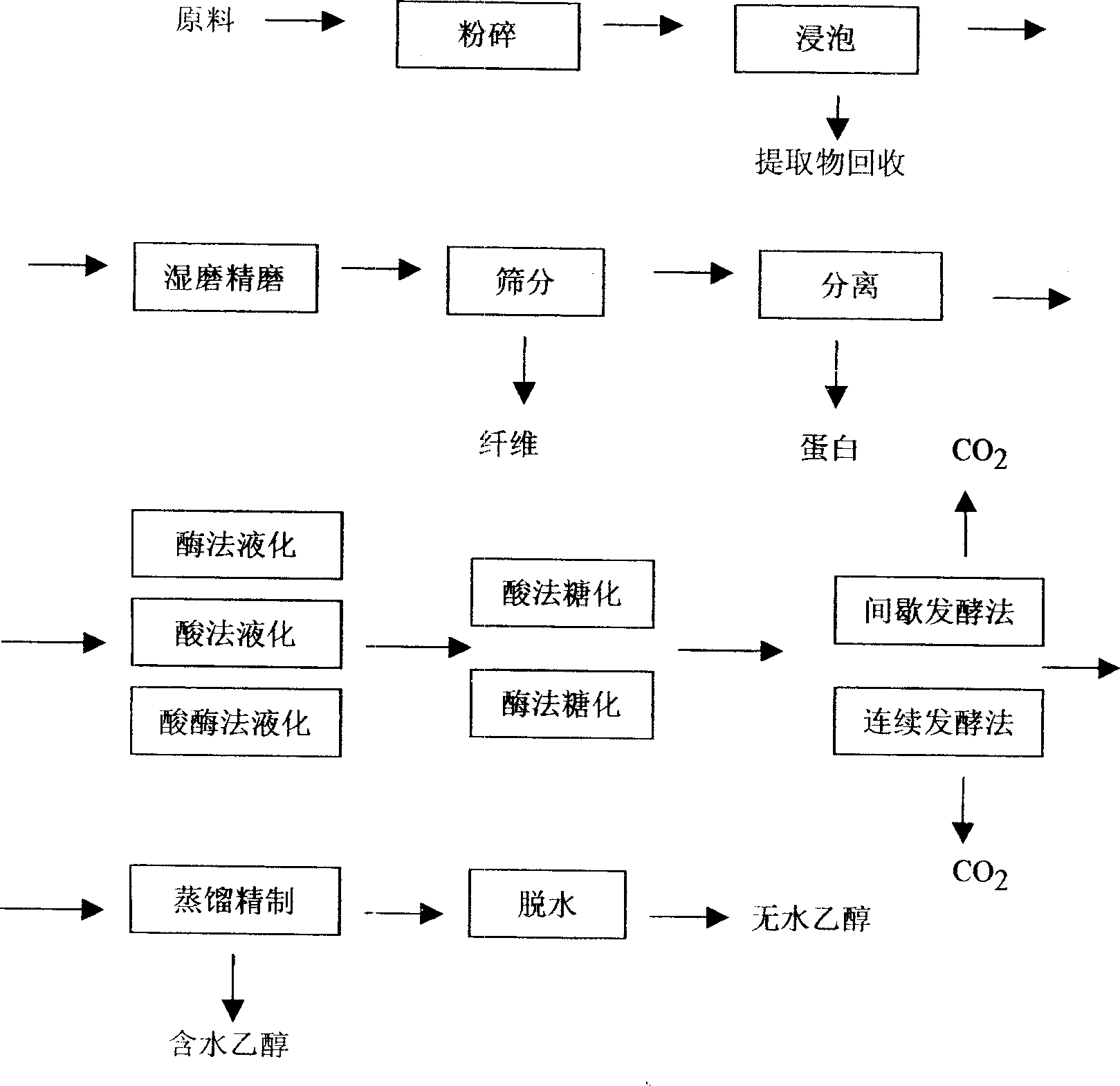

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1, prepare the former powder milk of acorn

[0037]According to the size of the harvested acorns, they are screened into different grades, and the bowl covers and shells are removed. Wash with water to remove impurities, and break into 2-5mm acorn kernel particles. Soak with an aqueous solution containing 0.2-0.6% sulfite at a temperature of 45-50°C for 64-72 hours. The number of soaking times is 6-8 times. The drained soaking liquid recovers the tannins. The soaked acorn particles are wet-milled and finely ground to obtain raw acorn powder milk with less tannin content.

Embodiment 2

[0038] Embodiment 2, adopt counter-current immersion method to prepare former acorn powder milk

[0039] According to the size of the harvested acorns, they are screened by grade, and the bowl cover and shell are removed. Wash with water to remove impurities, and break into 2-5mm acorn kernel particles. Adopt countercurrent soaking method, soak with aqueous solution containing 0.2-0.6% sulfurous acid or salt, soak at 45-50 DEG C, soak for 64-72 hours. Newly added acorns are in contact with the longest-soaked infusion; longest-soaked acorns are in contact with the newly added infusion. Discharge until the tannin content in the acorn particles reaches the standard. The drained infusion is concentrated to recover tannins. The soaked acorn particles are wet-milled finely to obtain raw acorn powder milk with very low tannin content.

Embodiment 3

[0040] Embodiment 3, prepare acorn starch milk

[0041] Adopt the raw acorn powder milk obtained in Example 2, sieve out fiber through 150-200 mesh, separate by-products such as protein by centrifugal method or air flotation method, obtain refined acorn starch milk through centrifuge and cyclone washing machine washing .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com