Automatic executing agency for fruit and vegetable on-line detection and separation

An automatic execution, fruit and vegetable technology, applied in sorting and other directions, can solve the problems of unstable mechanism, bruises, abrasions and crushes on the surface of fresh fruits, and achieves the effect of simple and compact structure, continuous production process and improved work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

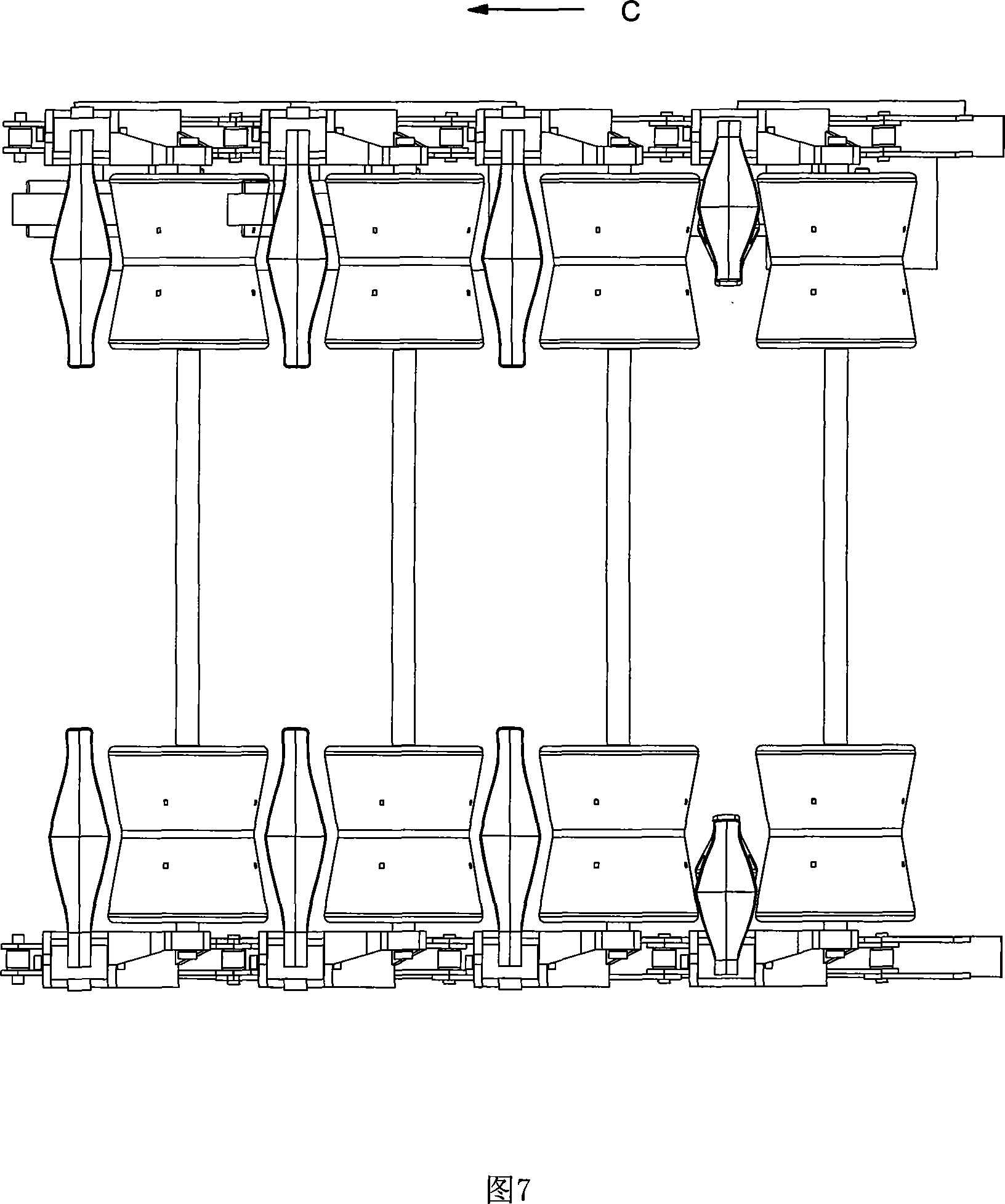

[0033] The automatic execution mechanism for fruit and vegetable online detection and sorting as shown in Figures 1-10 includes a frame 1 and a fruit and vegetable rolling device 2, an automatic fruit unloading device 3, an automatic photographing device and a transmission device. The fruit and vegetable rolling device 2 includes a card holder 201, a connecting shaft 202 and a supporting wheel 203; the automatic fruit unloading device includes levers 301, 302, electromagnets 401, 402 and a fruit unloading tray 5; the transmission device is a double chain 7 transmission; automatic The photographing device (not shown in the figure, which is a well-known technology) is located above the fruit and vegetable rolling device 2.

[0034] As shown in Figures 1 to 4, the diameter of the two ends of the supporting roller 203 is larger than the diameter of the middle part, which can make the fruits and vegetables turn more stable and prevent the fruits and vegetables from rolling away between...

Embodiment 2

[0040] The difference between this embodiment and the first embodiment is that the supporting wheel 203 is mounted on the connecting shaft 202, and the two connecting shafts 202 are jointly fixed on a holder 204. The fruit unloading tray 5 is located between the two supporting wheels 203 and is connected to the holders 201 and 204 through a pin 6 (that is, the holders 201 and 204 have slightly different structures). In this way, a part of the fruit unloading tray is hinged on the holder 201, the other part of the fruit unloading tray is hinged on the holder 204, and the holders 201 and 204 are installed on the chain at intervals. This solution can also achieve the goals of simple and compact structure, stable operation, accurate positioning, continuous production process and high efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com