Multi-head packet type loading machine and loading method

A multi-head, component technology, applied in electrical components, electrical components and other directions, can solve the problems of high equipment wear and failure rate, inability to meet the needs of expanding production, setting and changing troubles, etc., to reduce equipment wear and failure rate and adjust speed. The effect of convenience and speed, reducing the waste of time and distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

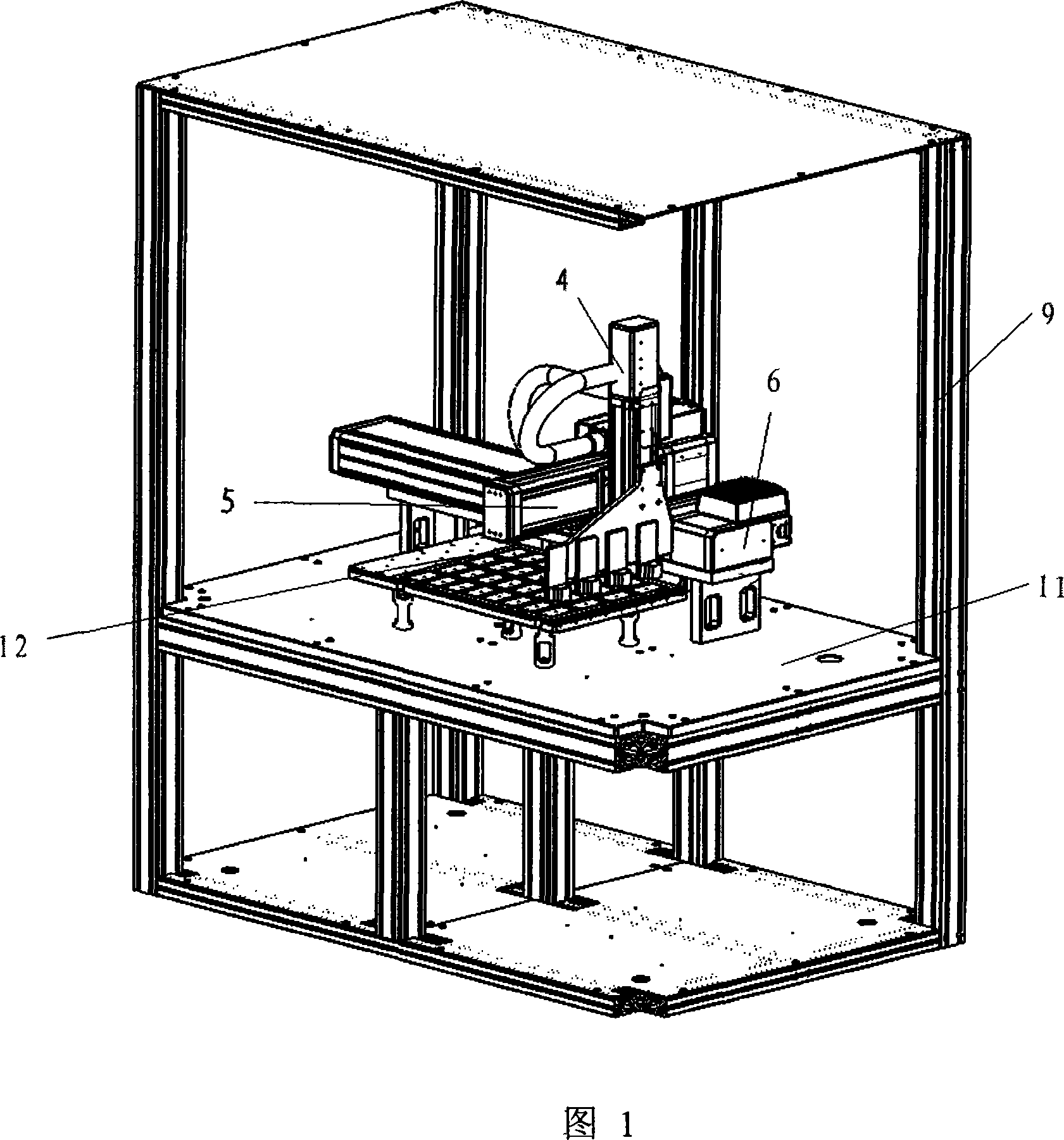

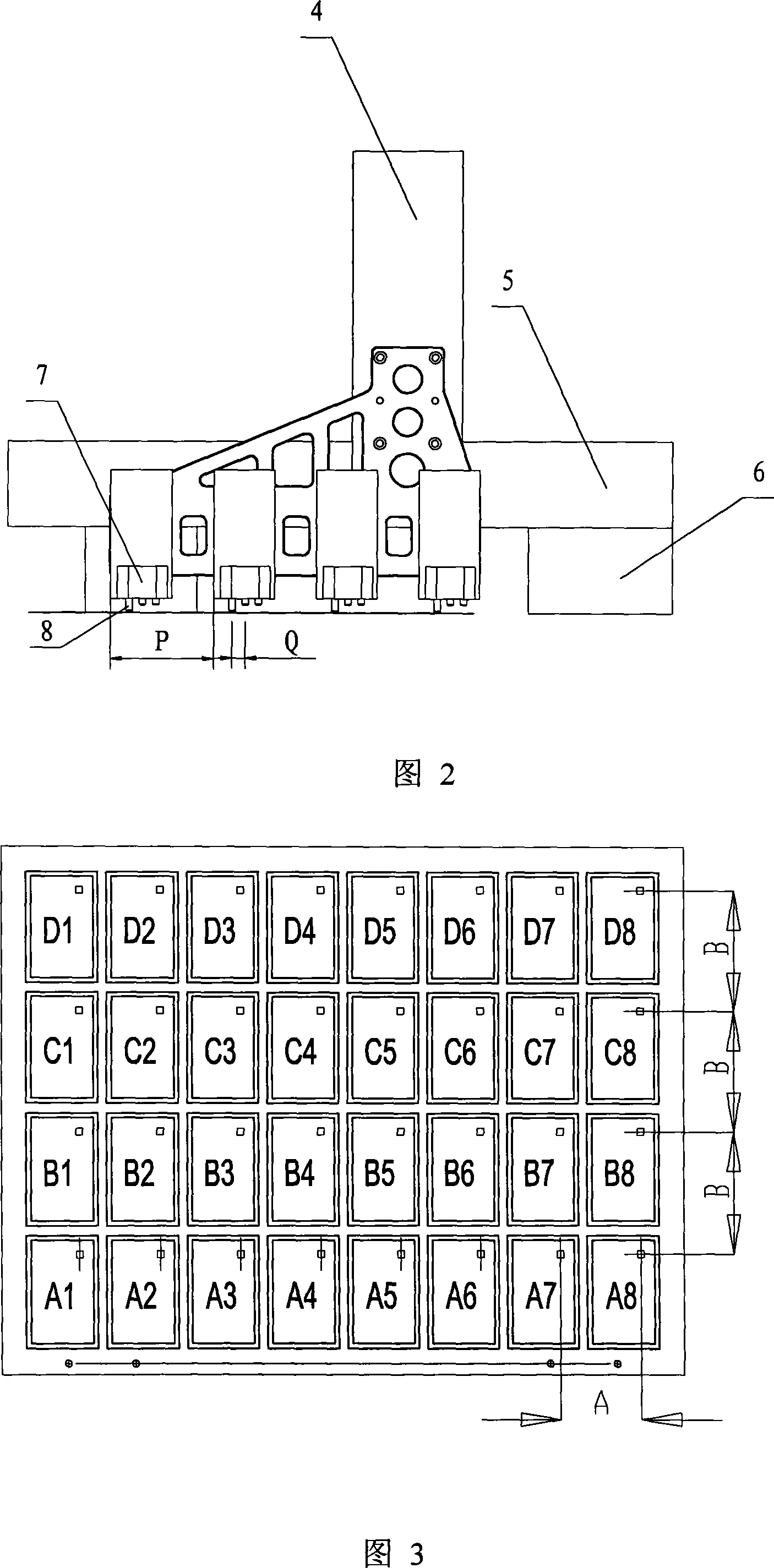

[0031] With reference to Fig. 1 and Fig. 2, multi-head grouping type filling machine of the present invention comprises body 9, is installed on the body 9 and is used for carrying the workbench 11 of filling base 12 and the filling head that is used to place to be filled on the filling base Assembly 7, and the multi-axis drive mechanism of filling head assembly 7. In an embodiment of the multi-head grouped filling machine of the present invention, the multi-axis drive mechanism includes three-dimensional X-axis, Y-axis and Z-axis (6, 5, 4 in the figure). Multiple filling head assemblies 7 are installed in the same device, and multiple filling heads 8 are installed on each filling head assembly 7 . When in use, as long as there is still something to be filled on the filling head, the moving distance of the equipment does not exceed the distance A+Q, and the filling can be carried out. Relying on automatic control technology and software, multiple filling heads 8 are assembled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com