Synthetic resin window section bar having metal qualitative sense and surface coating equipment thereof

A technology of synthetic resin and metal texture, which is applied to the device for coating liquid on the surface, special surface, coating, etc. It can solve the problems of difficult application of 3D products and cumbersome operation process, so as to achieve a wide range of applications and improve production efficiency , good durability and external aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

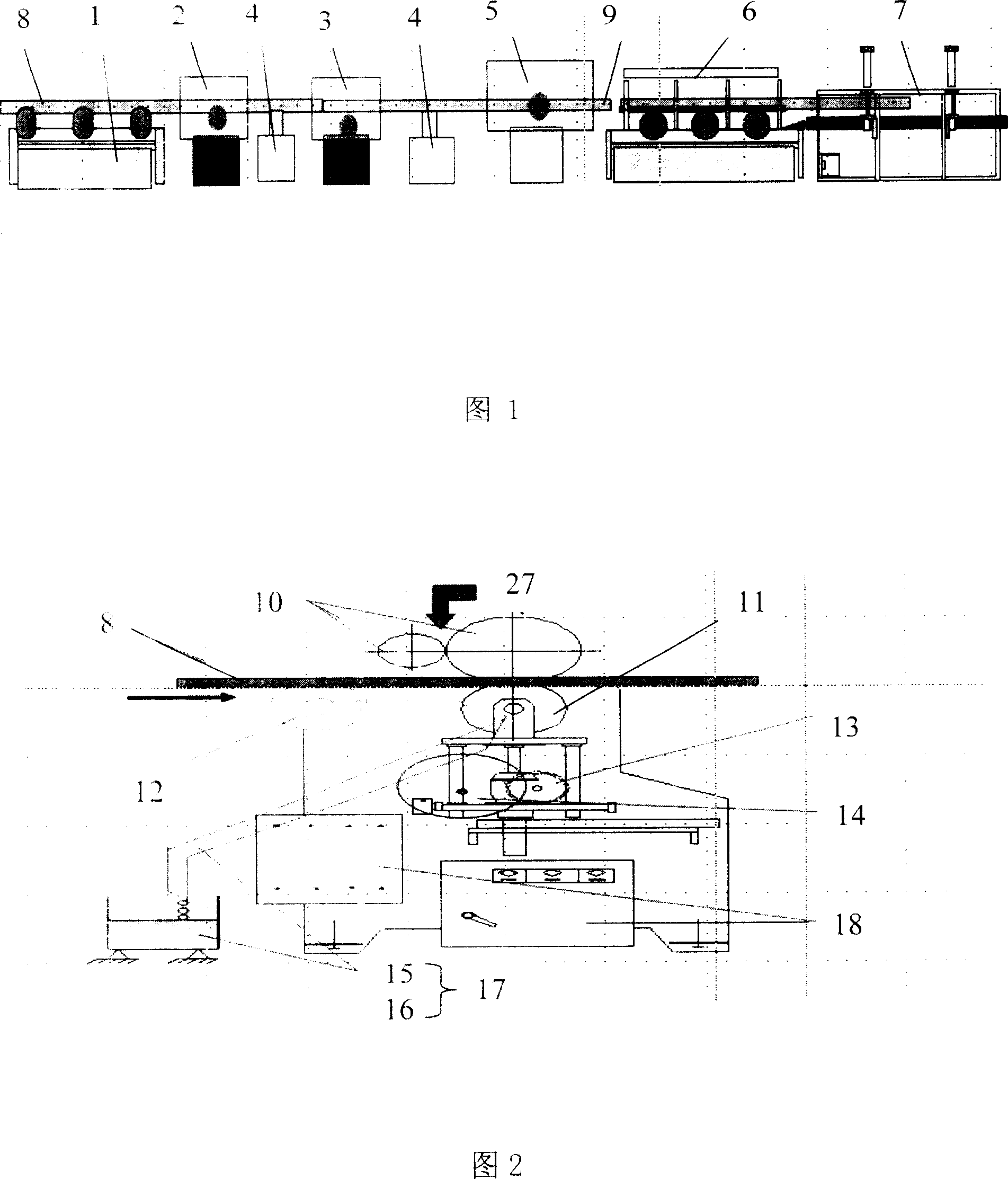

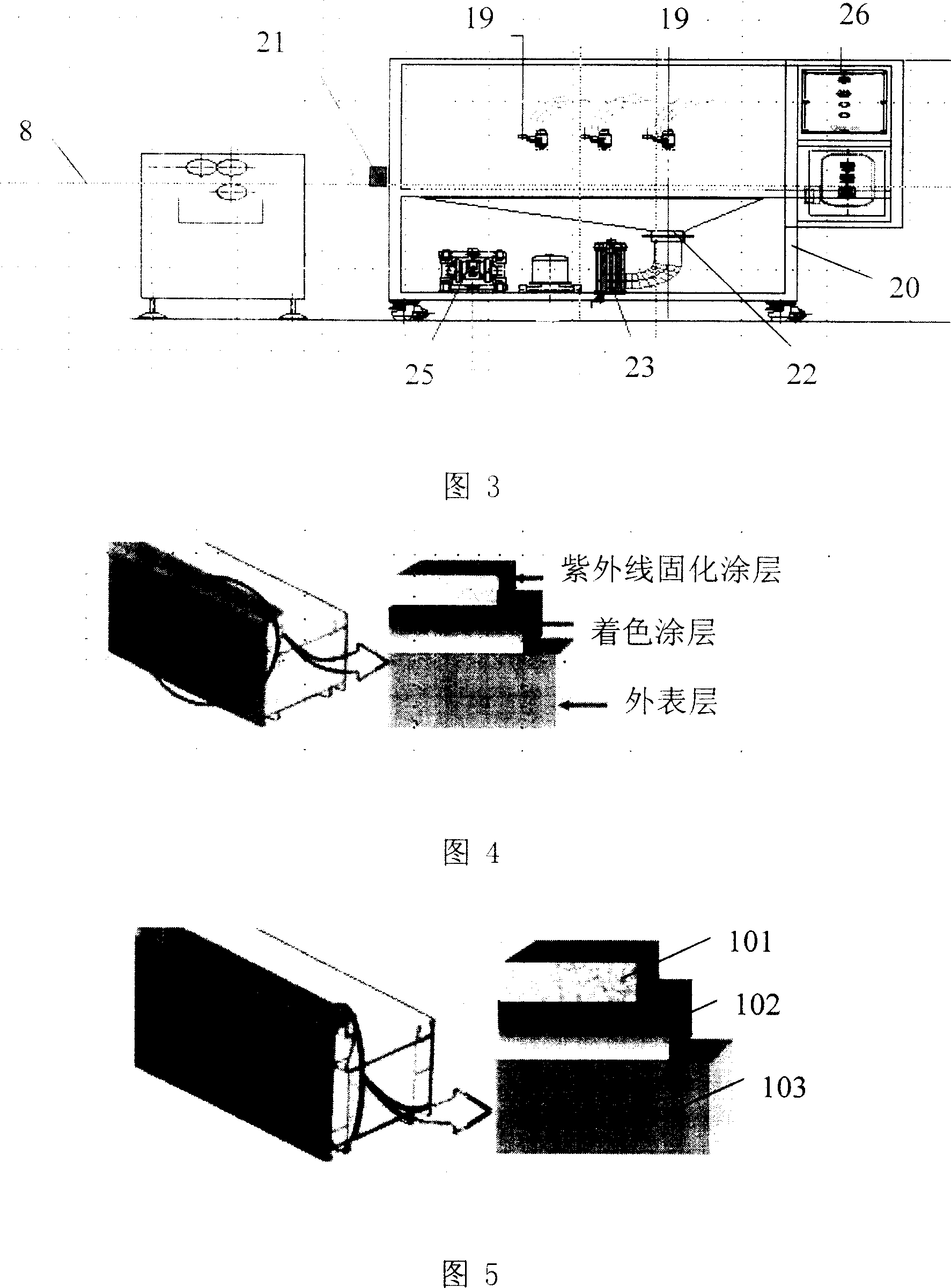

[0039] As shown in Figure 1, the synthetic resin window profile surface coating equipment with metal texture provided by the present invention comprises: be used to provide the feeder 1 of the common synthetic resin window profile 8 that utilizes molding method to make; After 1, a roll coating device 2 and a spray coating device 3 capable of rolling and spray coating an ultraviolet curable coating or a thermosetting coating on at least one surface of a common synthetic resin window profile 8; 2 and the conveyor belt 4 behind the spray coating device 3; it is possible to cure the UV curable coating or thermosetting coating coated on the surface of the common synthetic resin window profile 8 to form a UV curing or thermosetting coating, thereby making a metallic texture The curing part 5 of the synthetic resin window profile 9; and the transfer part 6 and the stacker 7 for transferring and stacking the synthetic resin window profile 9 with metallic texture.

[0040] As shown in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com