Modified wooden foot margin thread and processing method thereof

A processing method and technology of base line, which is applied in the field of interior decoration floor processing, can solve the problems of affecting the service life and appearance of base line, easy peeling of decorative paper, and consumption of wood, etc., so as to maintain natural ecological balance and save natural and precious wood, high definition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

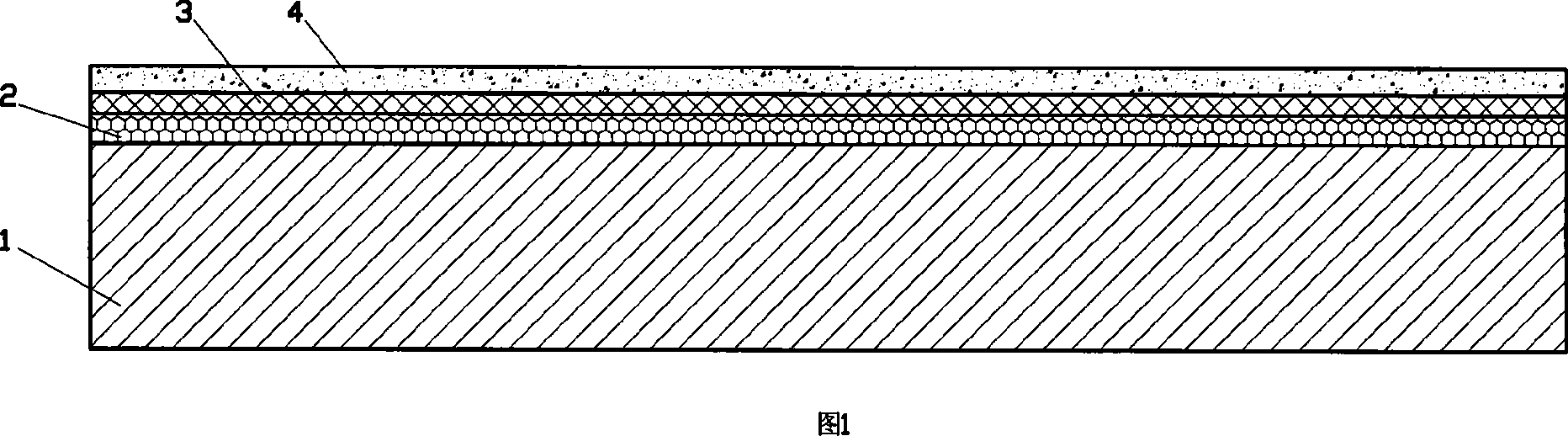

[0028] Referring to Fig. 1, an improved wooden base line includes a base material 1, and its structural characteristics are: a moisture-proof layer 2, a printed texture layer 3 forming a texture and a surface protection paint layer 4 are sequentially provided on the base material 1.

[0029] The moisture-proof layer 2 is formed by coating the base material 1 with paint with high adhesion, and has the functions of covering the ground color and waterproofing. The printed texture layer 3 is formed by printing a simulated real wood grain texture pattern by a roller coater; the surface protective paint layer 4 is formed by coating a protective paint.

[0030] The manufacturing process of the present invention will be described below by taking the finished base line printed with wood grain texture as an example. It includes the following steps:

[0031] Divide the base material (such as high-density fiberboard, reinforced composite base material) into blanks to make the base line s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com