Composite degradable soil nutrition amendment and preparation method thereof

A composite, conditioner technology, applied in soil conditioning materials, chemical instruments and methods, fertilizer mixtures, etc., can solve the problems of lack of water supply stimulation effect and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

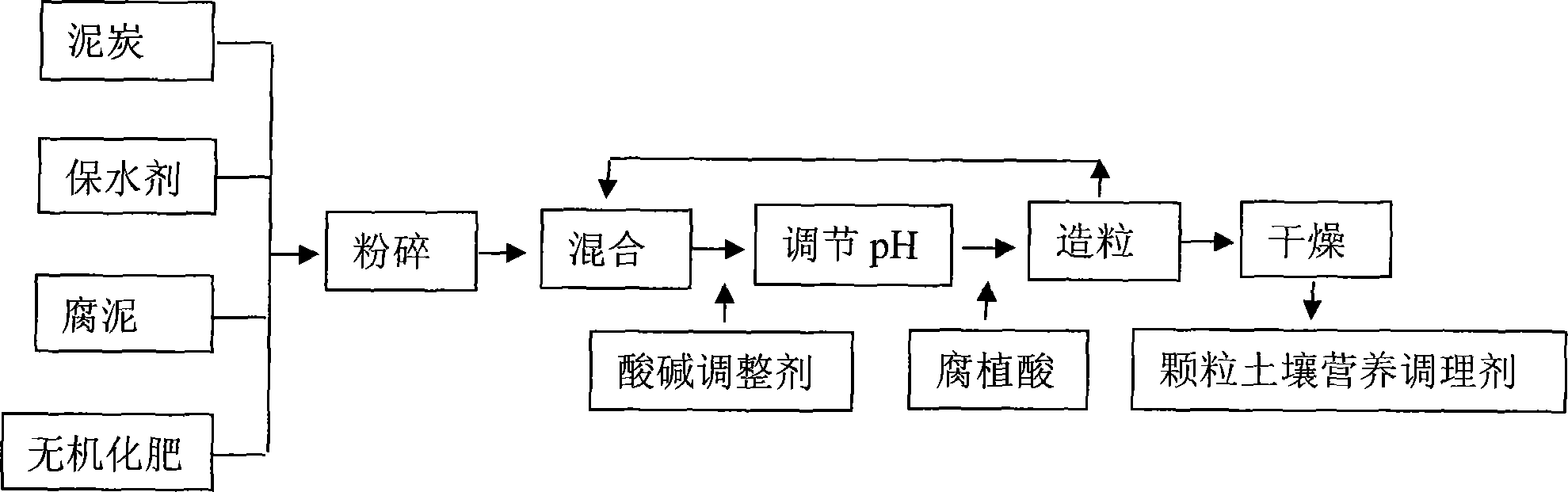

Method used

Image

Examples

Embodiment 1

[0026] In parts by weight, 60 parts of component A peat (organic matter 50%, water content 25%), 3 parts of component B sodium humate (containing humic acid 0.1%), 2 parts of component C biodegradable Superabsorbent resin (pH8.0, moisture 5%, particle size below 0.5mm), 30 parts of component D sapropel (water content 40%, organic matter content 10%), 5 parts of component E (2 parts urea+ 1.5 parts of superphosphate + 1.5 parts of potassium chloride), mix well, and crush into powder.

Embodiment 2

[0028] In parts by weight, 70 parts of component A peat (organic matter 50%, water content 20%), 1 part of component B humate, 1 part of component C biodegradable superabsorbent resin (pH8, Moisture 5%, particle size below 1.0mm), 23 parts of component D sapropel (water content 40%, organic matter content 10%), 5 parts of component E (2 parts of urea + 1.5 parts of limestone + 1.45 parts of potassium sulfate +0.05 parts of zinc sulfate), mix well, and adjust the pH value with component F (20% ammonia water), so that it is controlled at about 8.

Embodiment 3

[0030] Component A peat (organic matter 58%, water content 30%), component C biodegradable superabsorbent resin (pH8, water content 5%), component D sapropel (water content 44%, organic matter content 3.5%) Component E (urea+overstone+potassium chloride) is pulverized to less than 1mm, according to parts by weight, 90% of component A, 0.5% of component C, 4.5% of component D sapropel (water content 44% , organic matter content is 3.5%), 5% component E (2 parts of urea + 1.5 parts of stone + 1.5 parts of potassium chloride) is mixed evenly, sent to the granulator, and sprayed on the top of the rolling material bed. B, granulation for 10 minutes. Dry at 130°C for 25 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com