Operation mechanism moving type remote-operation hoist

A technology of operating mechanism and crane, which is applied in the field of lifting machinery to achieve the effect of filling the technical gap, advanced technology and superior performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

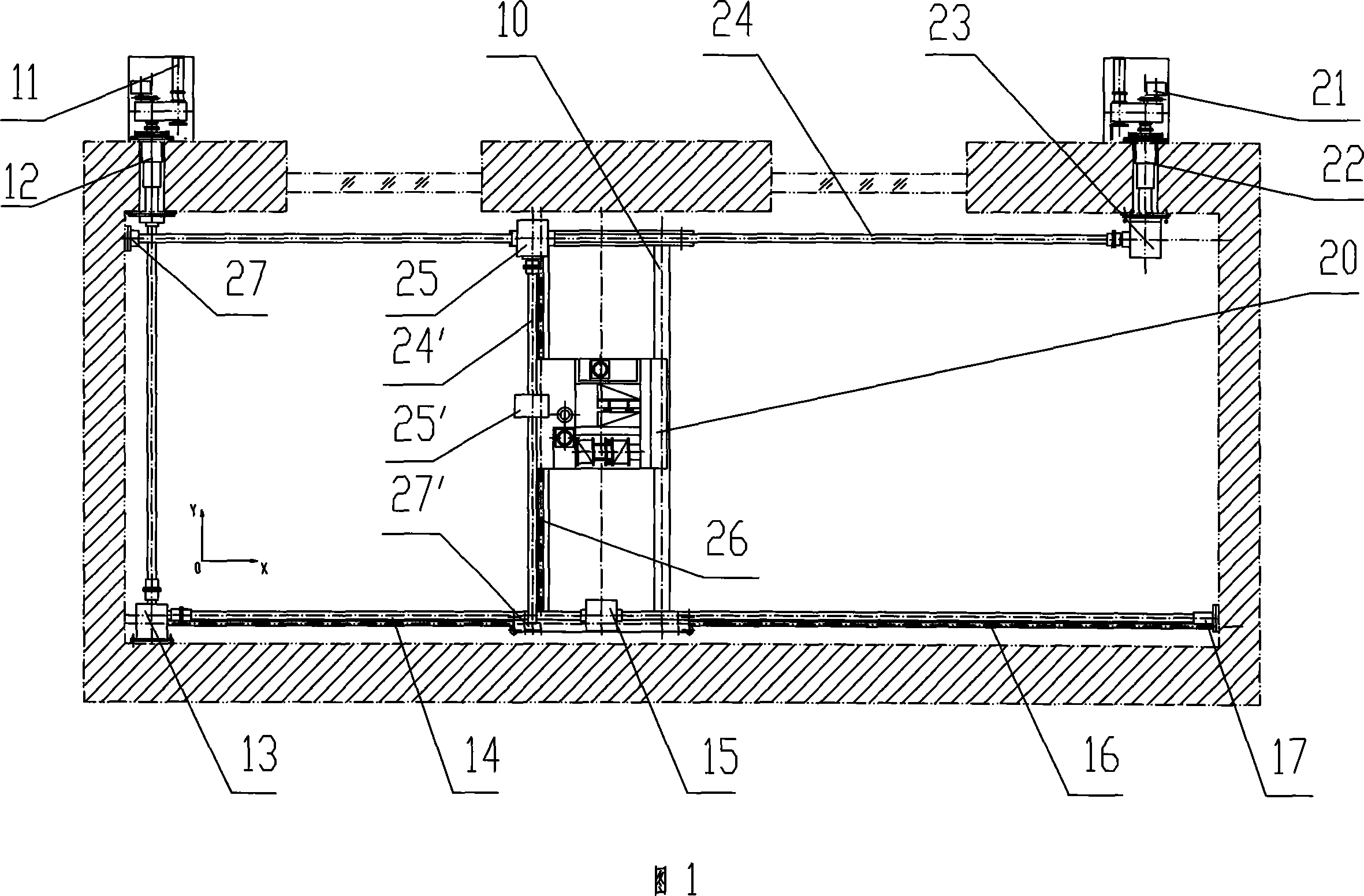

[0016] Now in conjunction with accompanying drawing, the present invention is described in further detail:

[0017] As shown in Fig. 1, the operating mechanism of the present invention is removed from the type remote control crane, which includes a crane bridge, a cart operating mechanism, a through piece I, a fixed commutator I, a transmission square shaft I, a sliding commutator I, and a gear tooth Bar meshing pair I, shaft end fixer I, trolley, trolley running mechanism, fixed commutator II, transmission square shaft II, shaft end fixer II, sliding commutator II, transmission square shaft III, sliding commutator III , Shaft end holder III, rack and pinion meshing pair II.

[0018] The operating mechanism of this kind of remote control crane with moving mechanism is removed from the main body of the crane, and is fixedly placed outside the factory building. It does not move with the crane, but drives the crane to run through a transmission system.

[0019] The transmission ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com