Metallurgical industry integrative plan scheduling system and method

A technology of comprehensive planning and scheduling and comprehensive planning, applied in the direction of calculation, instrumentation, data processing and application, etc., can solve the problems of loose interrelationship, failure, and disjointed planning, and achieve the effect of enhancing integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

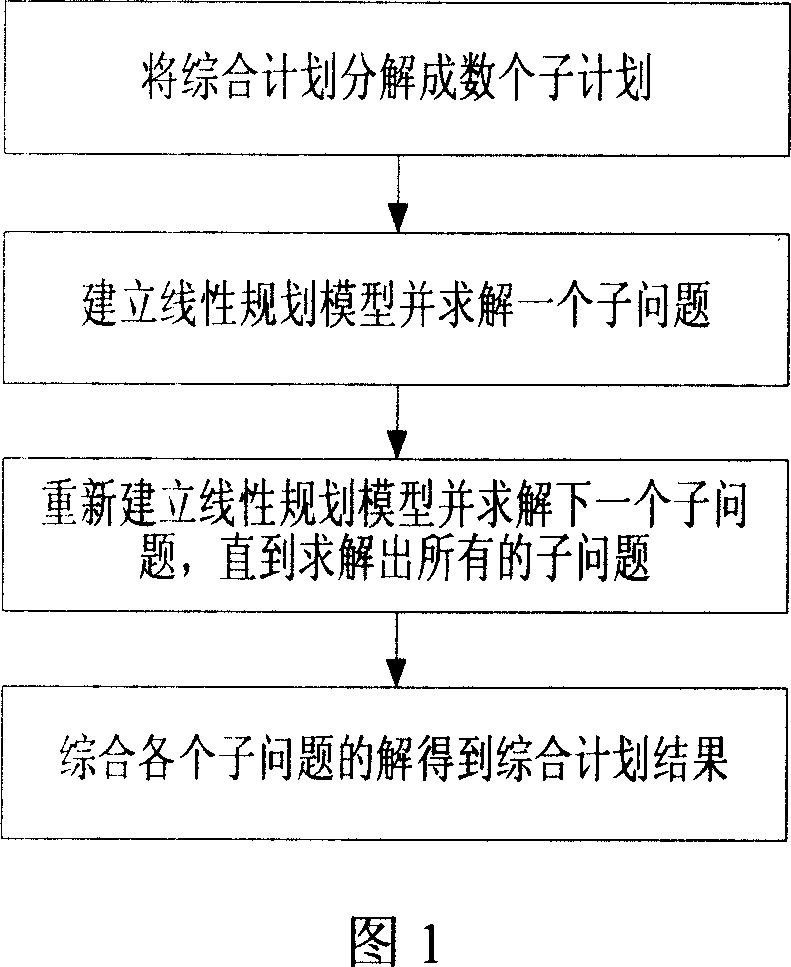

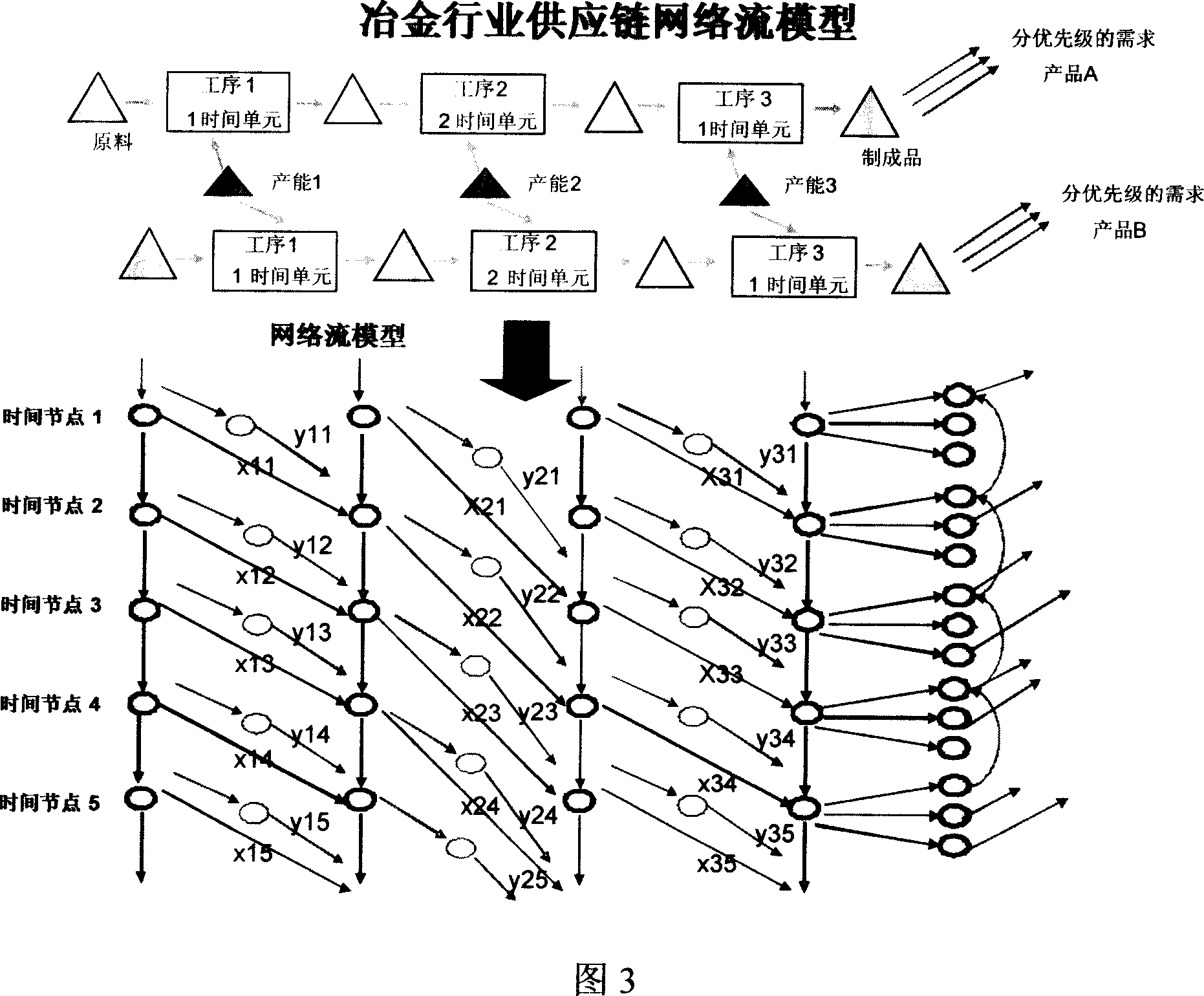

[0013] As shown in Figure 1, the technical scheme of a comprehensive planning and scheduling system and method for the metallurgical industry of the present invention includes the following steps, the first step is to divide the original comprehensive planning optimization problem into several sub-problems; the second step is to establish Linear programming model and solve a sub-problem; the third step, deduct the production capacity, materials and other resources occupied by the sub-problem in the second step, re-establish the linear programming model and solve the next sub-problem until all sub-problems are solved; fourth The first step is to synthesize the solutions of each sub-problem to obtain the comprehensive plan result.

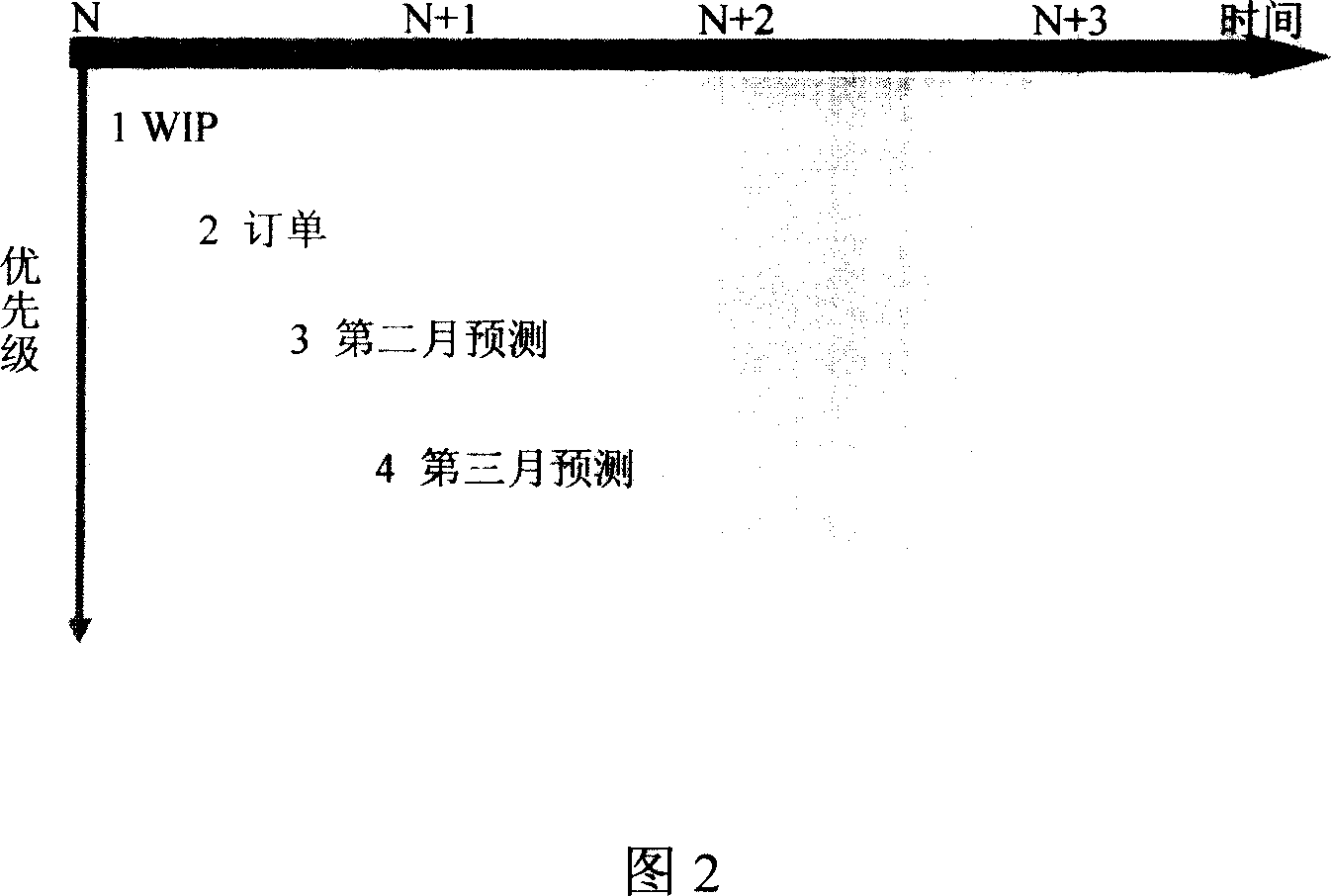

[0014] Take Baosteel's comprehensive monthly process plan as an example. First, decompose the problem and divide the original comprehensive planning optimization problem into several sub-problems. The time span of Baosteel's comprehensive monthly pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com