Composite hollow ceramic solar energy heat collection plate production method

A technology of solar collector plate and composite ceramics, which is applied in the parts of solar collectors, solar collectors, solar thermal energy, etc., can solve the problem of attenuation of sunlight absorption rate, complex structure and manufacturing process of vacuum glass tube collectors , high price issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

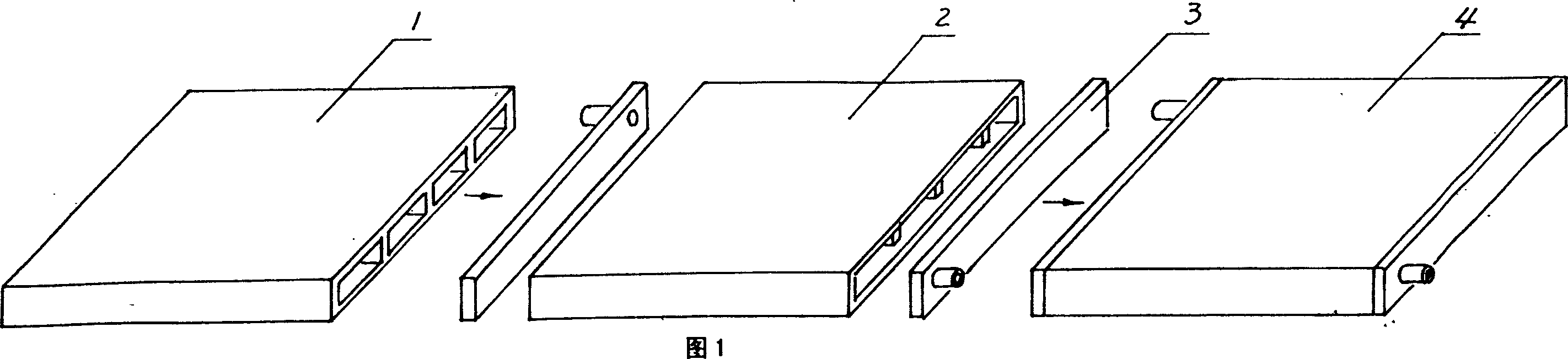

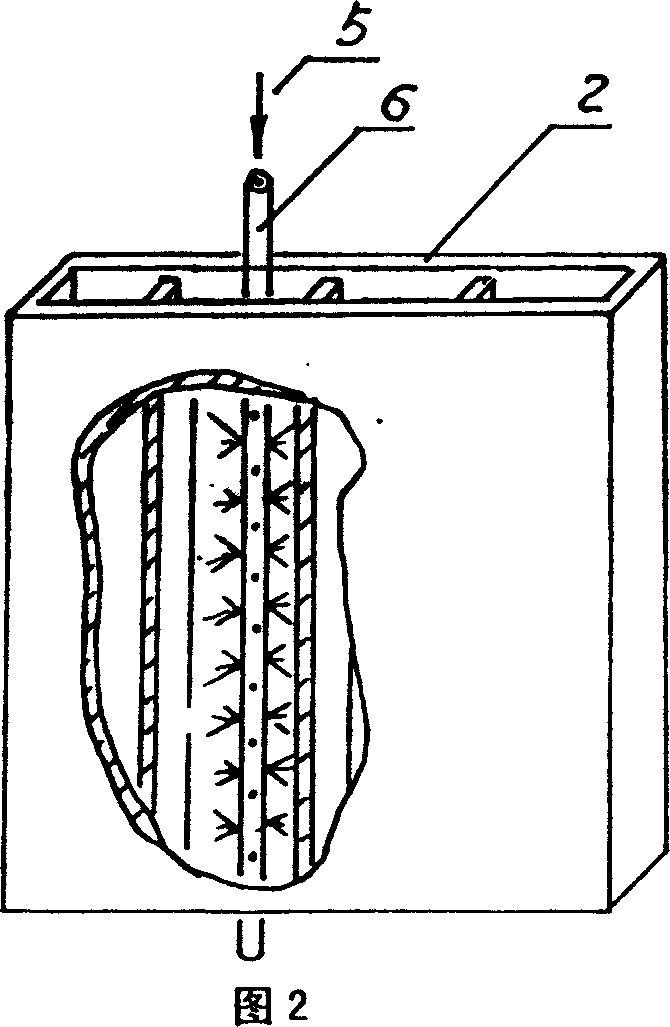

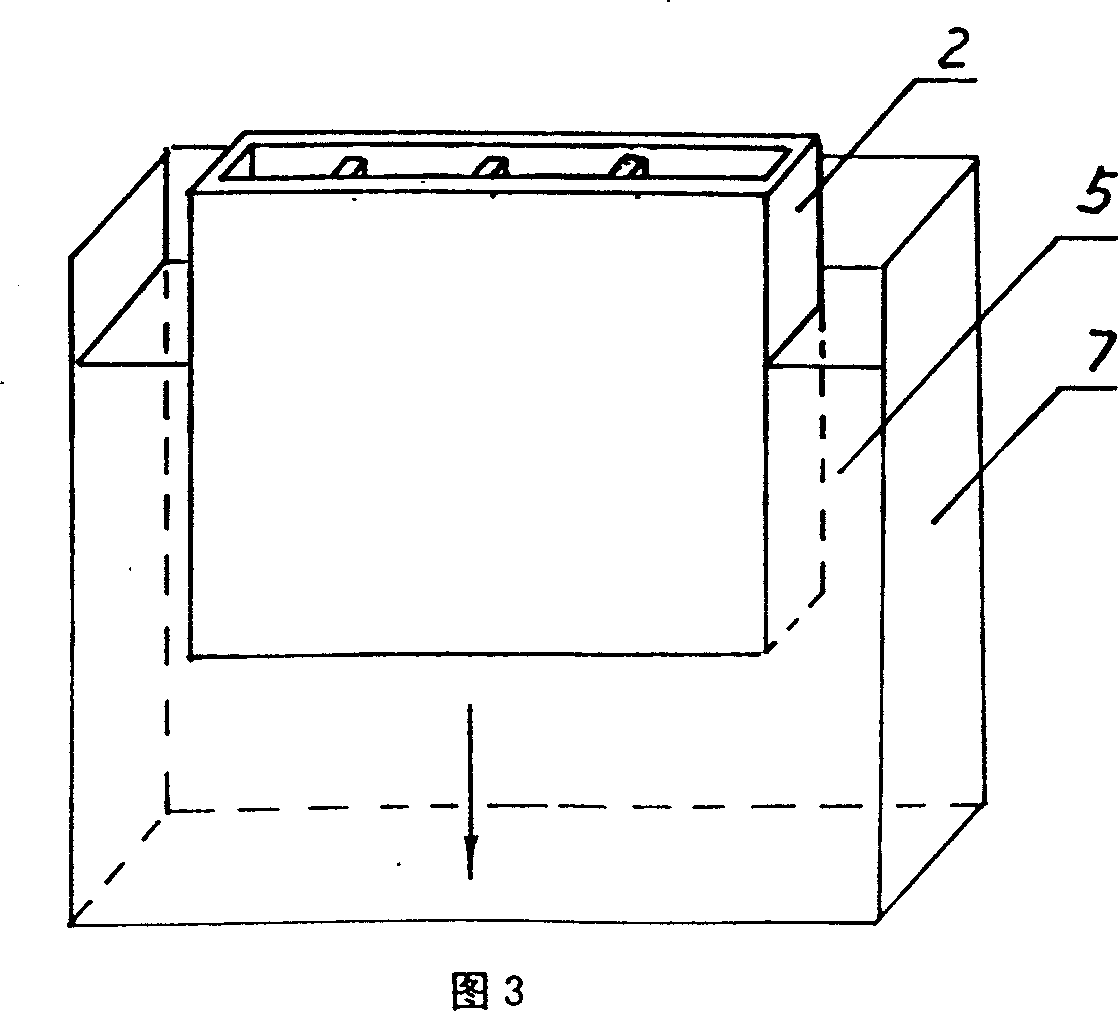

[0030]1. Common ceramic raw materials clay, quartz, feldspar are crushed and ball-milled to become ordinary ceramic mud. After passing through a 200-mesh vibrating screen, excess water is removed by pressure filtration to form a mud cake. After rough refining, a vacuum mud mixer is used to squeeze it into a mud section. Put it into the stale house, and then use a vacuum extruder to extrude it into a porous through-hole plate with a width of 500 mm, a thickness of 38 mm, 12 holes in the middle, a thickness of the hole wall of 5 mm, and a length of 1000 mm. The partial partition wall at the end of the through hole connects the two ends of the through hole to form a through hole plate connected to the end of the hole. The two ends of the through hole plate are bonded with plugs with inlet and outlet of the same material, which becomes a ceramic hollow plate green body. As shown in Figure 1, after the ceramic hollow green slab is dried, stand it upright to extract 65% of vanadium t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com