Method for preparing soluble heart trefoil protein

A kind of technology of alfalfa protein and alfalfa leaf, applied in the field of plant protein, can solve the problems of low content, poor solubility, dark green color, etc., and achieve the effect of broad application prospects, good water solubility, and light color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

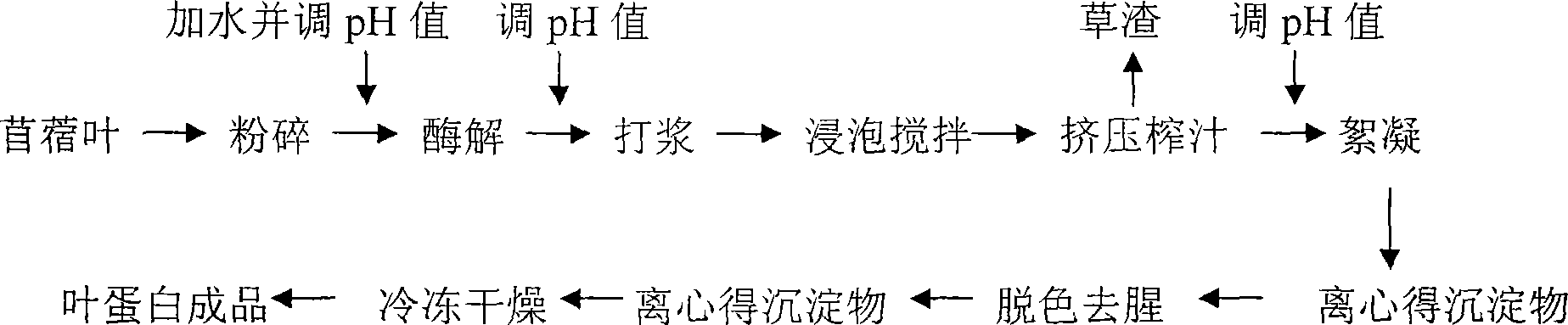

Method used

Image

Examples

Embodiment 1

[0009] Alfalfa leaves are crushed to 40 meshes, the amount of water added is material: water=1:6, the pH value is adjusted to 4.5, the enzyme is cellulase, the enzyme amount is 2.5% (w / w), the reaction temperature is 45°C, and the reaction time is 4.5 Hours; then adjust the pH value to 7.8, use a tissue masher to beat for 3 minutes, soak and stir for 30 minutes, squeeze and squeeze the juice for 3 minutes to obtain juice; then adjust the pH value to 4.0, flocculate for 5 minutes, and then put it on a 3000 rpm / separation centrifuge Centrifuge for 12 minutes to obtain the precipitate; then use 95% ethanol to extract the color and remove the fishy smell, the amount of ethanol is as follows: ethanol=1:11, the extraction temperature is 42°C, and the extraction time is 6 hours; then centrifuge at 1500 rpm for 4.5 minutes A precipitate was obtained; and then freeze-dried to obtain a soluble alfalfa leaf protein product with a crude protein content of 78.8%.

Embodiment 2

[0011] Alfalfa leaves are crushed to 40 meshes, the amount of water added is material: water=1:7, the pH value is adjusted to 4.5, the enzyme is cellulase, the amount of enzyme added is 3.0% (w / w), the reaction temperature is 45 ° C, and the reaction time is 5 Hours; then adjust the pH value to 7.8, use a tissue masher to beat for 3 minutes, soak and stir for 30 minutes, squeeze and squeeze the juice for 3 minutes to obtain juice; then adjust the pH value to 4.0, flocculate for 5 minutes, and then put it on a 3000 rpm / separation centrifuge Centrifuge for 12 minutes to obtain the precipitate; then use 95% ethanol to decolorize and remove the fishy smell, the amount of ethanol is as follows: ethanol=1:12, the extraction temperature is 50°C, and the extraction time is 5 hours; then centrifuge at 1500 rpm for 3.5 minutes to obtain the precipitate and then freeze-dried to obtain a soluble alfalfa leaf protein product with a crude protein content of 79.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com