Connector for automobile component

A technology of connectors and components, applied in the direction of connecting components, thin plate connections, vehicle parts, etc., can solve the problems of smaller structural space, unusable, no tight fit, etc., and achieve the effect of reduced production cost and simple processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

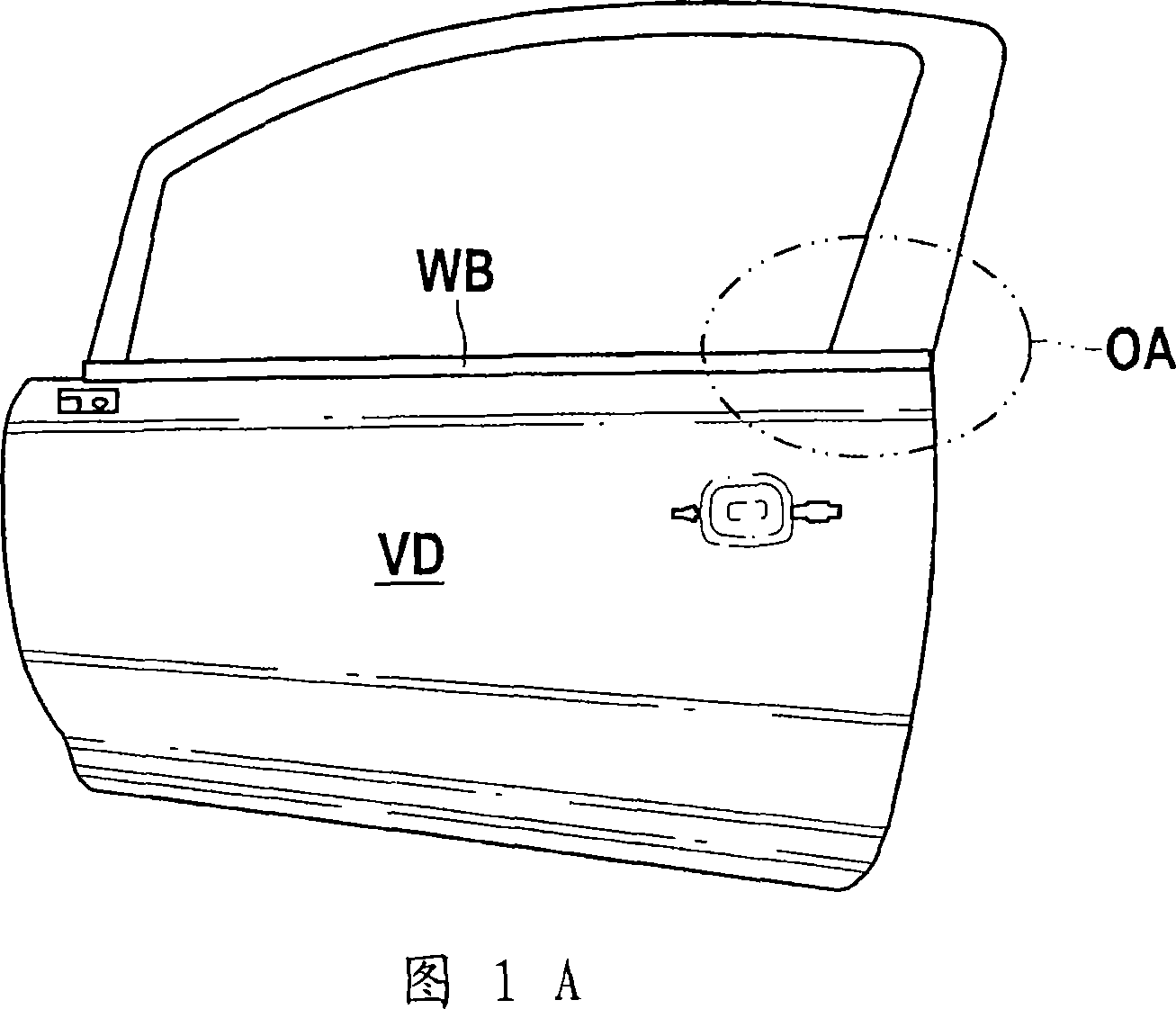

[0039] FIG. 1A shows a side view of a vehicle door VD (vehicle door) with a window belt WB (waist belt), which is not fastened in the overlap area OA (overlap area) at the free end of the door VD.

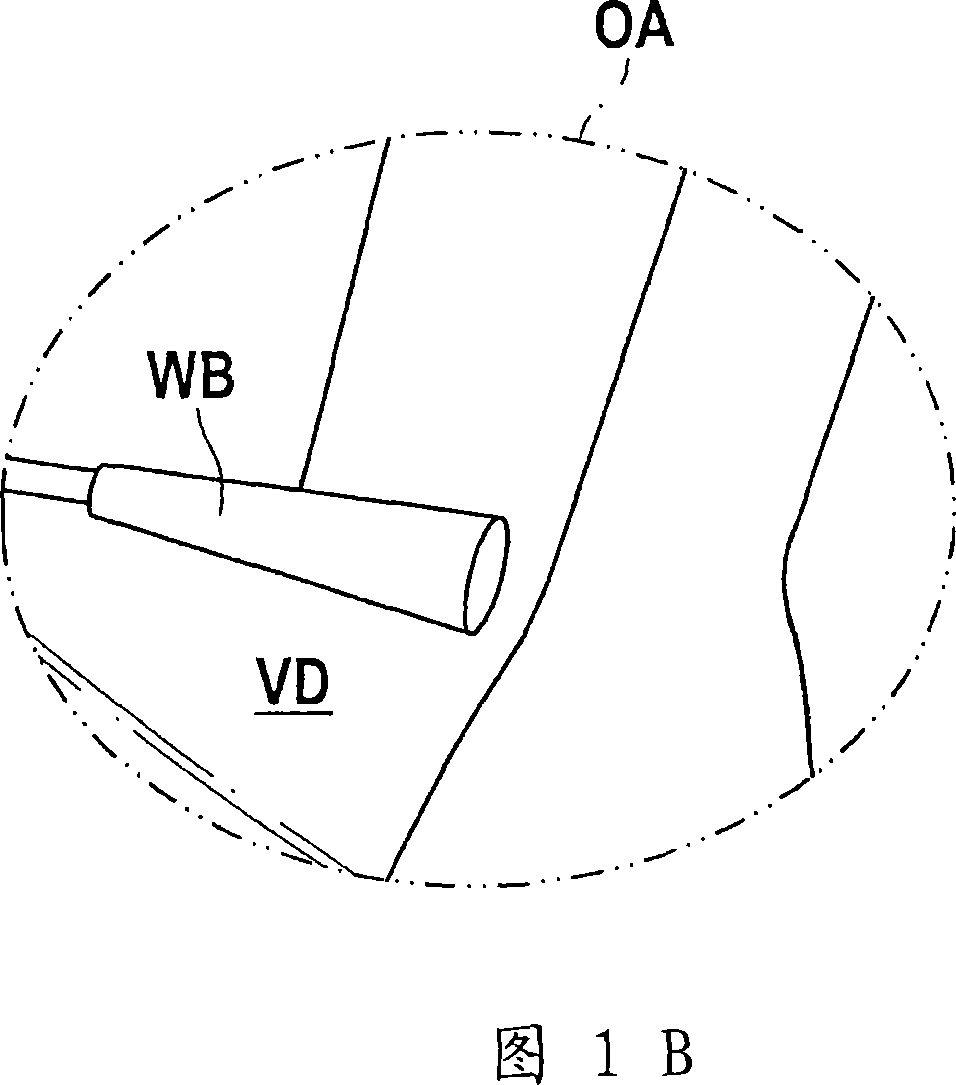

[0040] FIG. 1B shows an enlarged view of the area OA of FIG. 1A. It can be seen from this figure that the stiffness of the side strip WB is not sufficient to secure it in the overlapping area OA of the outer skin of the door VD when the vehicle is in use. Due to the particularly narrow installation space in this area, however, fastening can be difficult without compromising the specified aesthetic requirements. This situation is further exacerbated by the required outward turning of the door frame.

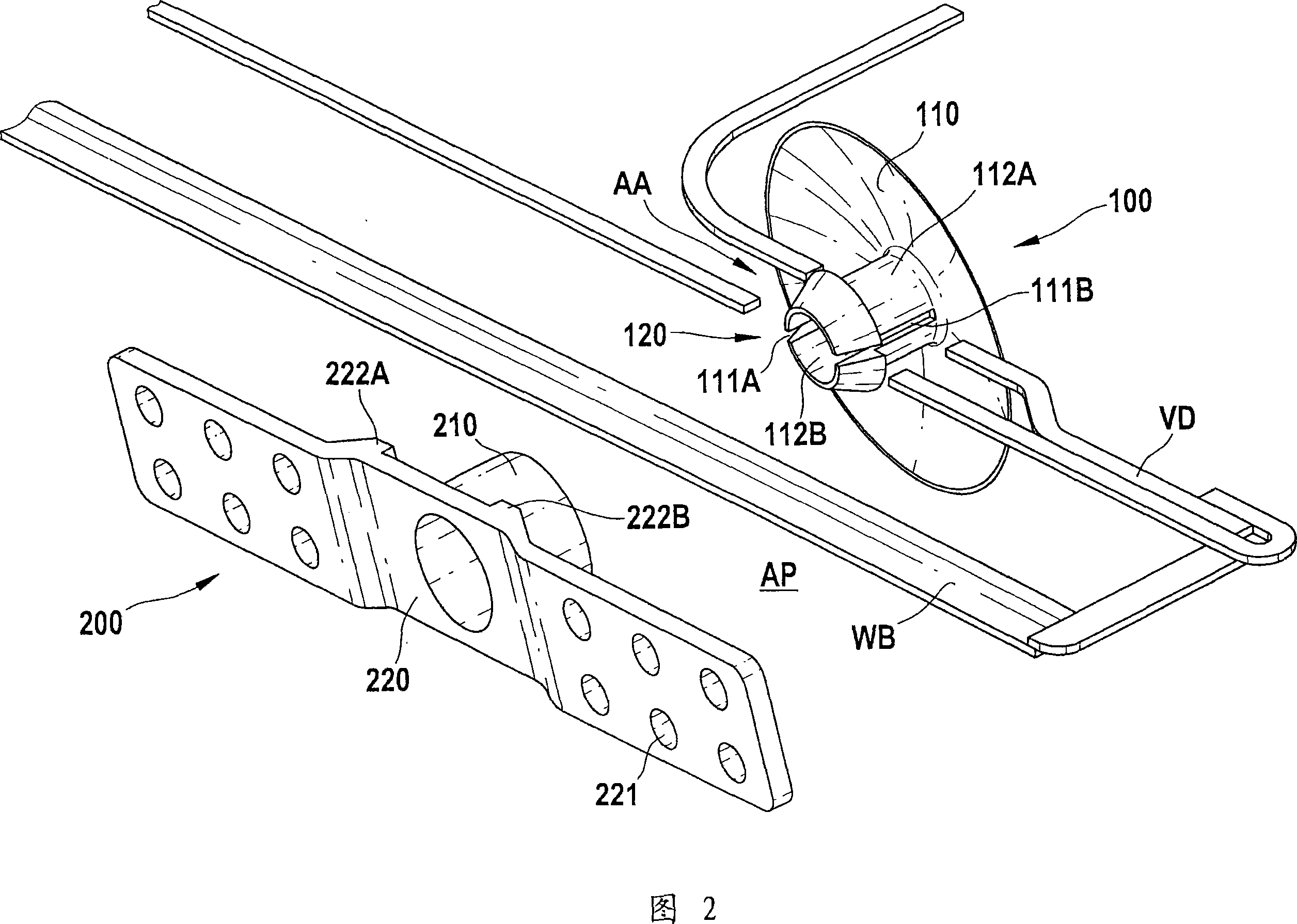

[0041] Fig. 2 shows a partially cut perspective view of the connecting element according to the present invention, the connecting element is in the assembly position AP (assembly position) on the automobile door VD shown in Fig. 1A, and its rivet 100 and its opposite support 200 are o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com