Emergency braking device for elevator and elevator

An emergency braking and elevator technology, which is applied in the field of elevators, can solve the problems of incompatibility of friction parts, inability to ensure friction, and poor pressing force, etc., and achieve high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Hereinafter, the emergency braking device for an elevator according to the present invention will be described with reference to the drawings.

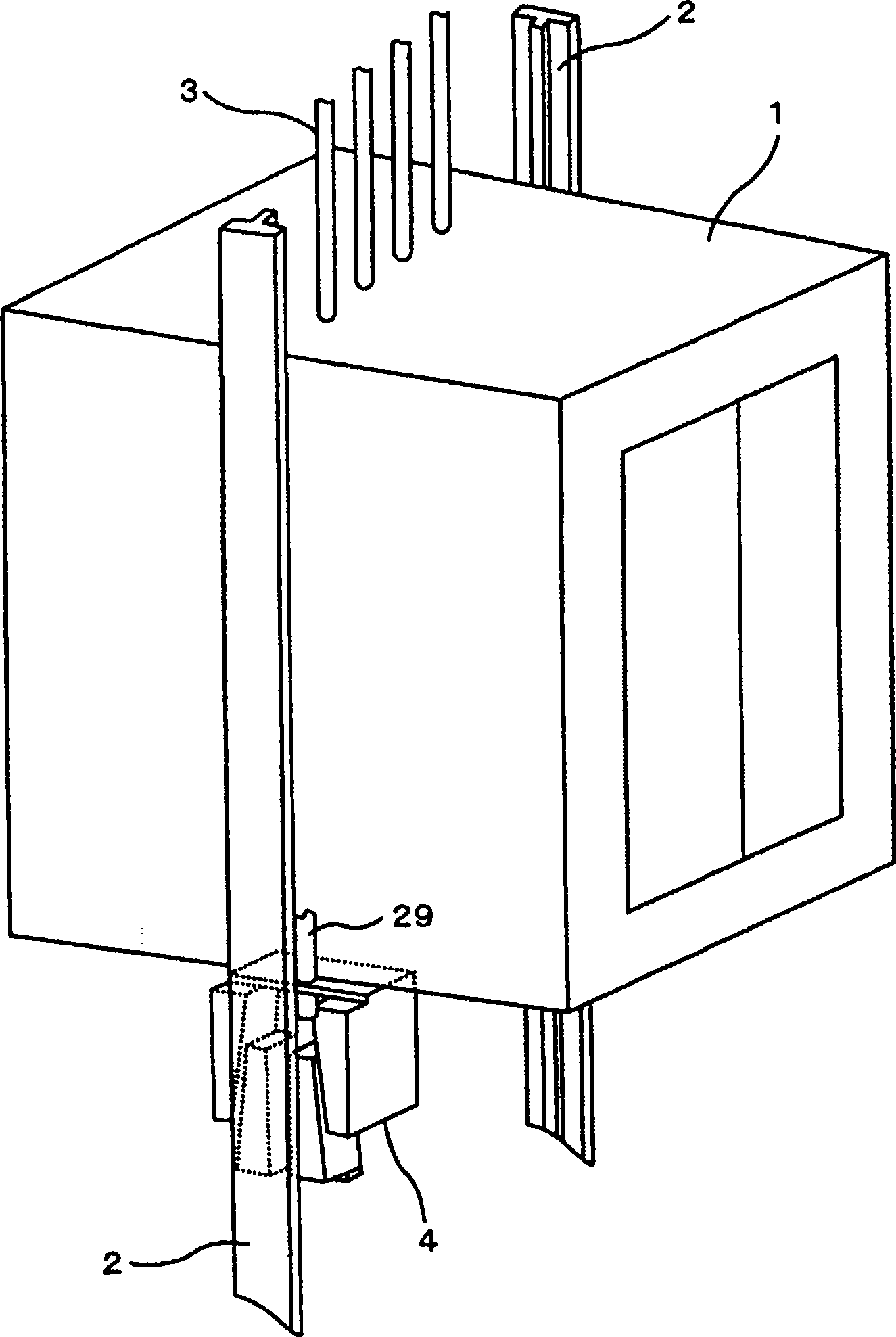

[0039] figure 1 It is a perspective view of the elevator car 1 of the elevator and the emergency braking device installed at the lower part of the elevator car 1. The elevator car 1 used to carry passengers is connected to the uppermost floor of the building (not shown) through the sling 3 drive system connection. In this figure, for ease of understanding, the detailed illustration of the elevator door opening and closing equipment and the outer frame is omitted.

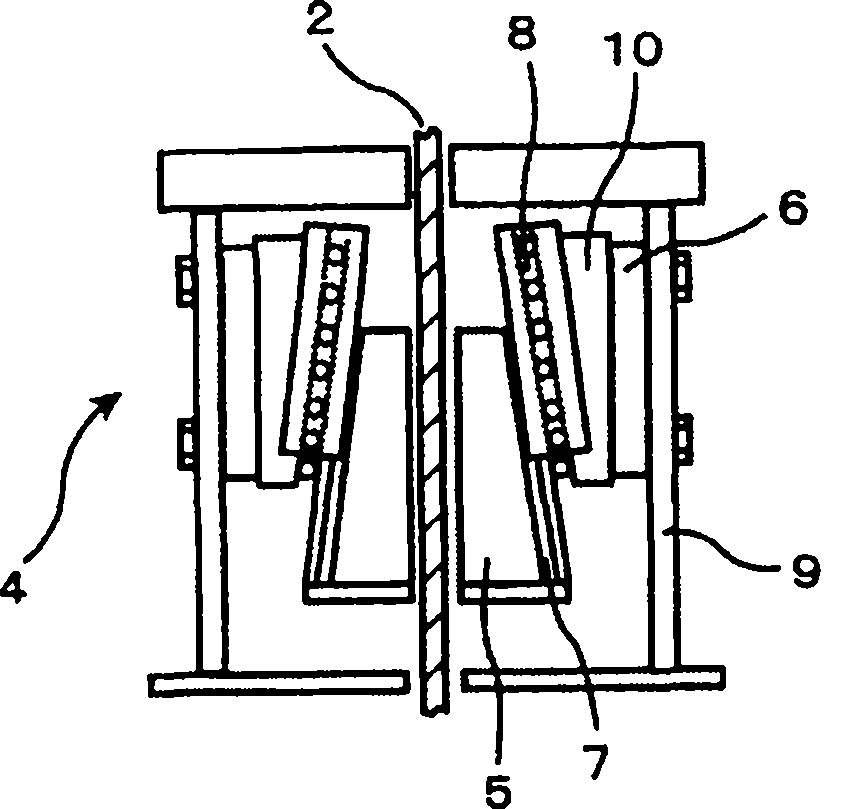

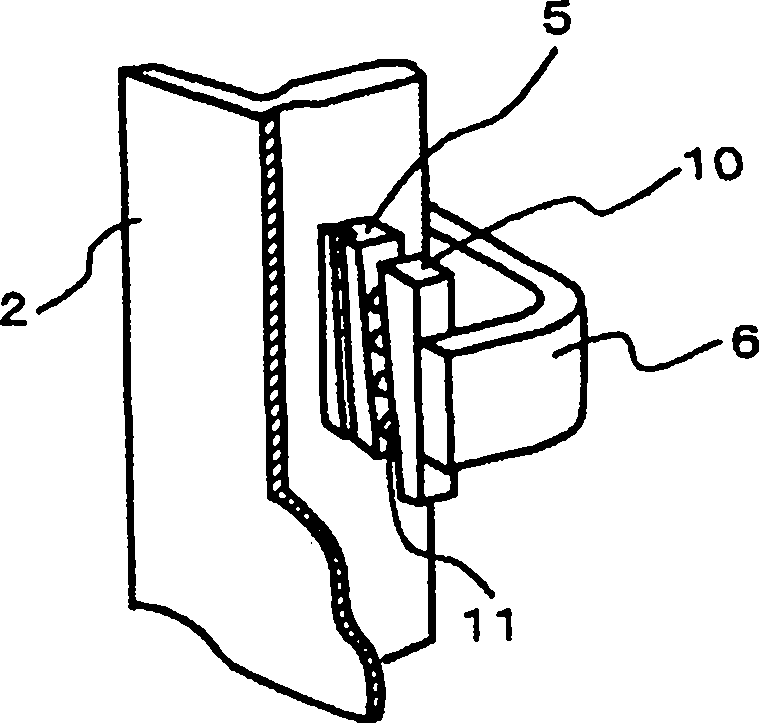

[0040] On both sides of the hoistway, a pair of guide rails 2 are provided to guide the elevator car 1 when going up and down. A pair of emergency stoppers 4 are provided at the lower part of the elevator car 1, and the pair of emergency stoppers clamp the T-shaped longitudinal rails of the respective guide rails 2 formed in a T-shaped cross-sectional shape. The p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com